IBanga eliPhezulu eliPhezulu leNtsimbi yeMbhobho yoMbhobho weSilidi weTitanium Umxokomezo wokwenza uMatshini weMibhobho yoShishino oomatshini bokwenza umbhobho

Ngokwesiqhelo ijolise kubathengi, kwaye yeyona nto sigxile kuyo ekubeni ingeyiyo kuphela yoyena mboneleli unoxanduva, othembekileyo nothembekileyo, kodwa neqabane labathengi bethu kwiBanga eliPhezulu eliPhezulu loMbhobho weSpeed Pipe Tube Mill iTitanium Duct Ukwenza uMatshini weMibhobho yoShishino loKuqulunqa uMbhobho Umatshini, Iimveliso ezenziwe ngexabiso lophawu. Sizimasa ngokuzimisela ukuvelisa nokuziphatha ngemfezeko, nangokuthanda abathengi basekhaya nakwamanye amazwe kushishino lwe-xxx.

Ngokwesiqhelo ijolise kubathengi, kwaye yeyona nto sigxile kuyo ekubeni ingeyiyo kuphela yoyena mntu unoxanduva, othembekileyo nothembekileyo umnikezeli, kodwa neqabane labathengi bethu.Umatshini Wokwenza uMbhobho waseTshayina kunye noMshini Wokwenza uMbhobho wentsimbi, Ukuthatha ingcamango engundoqo "yokuba yiNgxelo". Siza kubuyisela uluntu kwiimveliso ezikumgangatho ophezulu kunye nenkonzo elungileyo. Siya kuqala ukuthatha inxaxheba kukhuphiswano lwamazwe ngamazwe ukuze sibe ngabavelisi abakumgangatho wokuqala wale mveliso ehlabathini.

Isicelo&Mgangatho&Qaphela:

1. Ifanele UKUSHIYWA KWESITIMI ESIKABHABHONI KUNYE NENTENYE YE-ALLOY EPHANTSI, KWAKUNYE NAMANDLA OKUFANELEKILEYO WEBOILER, umbhobho, isithuthi, i-BUILDING, BRIDGE KUNYE NEZINYE IZIQULATHO, ezifana ne-Q345.

2. Umgangatho esidibene nawo: GB/T5117 E5016, AWS A5.1 E7016 & A5.1M E4916, ISO2560-A:E 42 3 B 1 2, ISO 2560-B: E4916 A

Imiqathango ye-welding:

Ngaphambi kwe-welding, i-weldment kufuneka ingabikho ngokupheleleyo kwioli, i-rust, umswakama, njl.; ukomisa kwi-350 ° C ngeyure; kunye nokumisa ngokusetyenziswa

3. Sebenzisa i-welding yokudlula emxinwa kunye ne-arc welding emfutshane; Uqhagamshelo lwe-AC kunye ne-DC umva.

Ingasetyenziselwa ukuwelda intsimbi yekhabhoni ephantsi kunye ne-490MPa yamandla aphezulu entsimbi yombhobho wentsimbi edibeneyo, inokuqonda ukuwelda kwecala elinye lokubumba kabini.

I-electrode yeyohlobo oluphantsi lwe-hydrogen, umbhobho we-welding kunye nesakhiwo ngokubanzi sengcambu ye-weld, inokuqonda i-welding yecala elinye-macala amabini, ngoko inokugcina isithende se-welding yokucoca, ukwenzela ukuba ukusebenza kakuhle kwe-welding kuphuculwe. .

Amanqaku aphambili enkqubo:

1, ukomisa ngaphambi kokusetyenziswa, 300 ~ 350 ℃ ukomisa imizuzu engama-30 ~ 60;

I-2, khetha i-current efanelekileyo kunye ne-groove, ukuze ufumane i-weld back weld;

3. Xa ucima i-arc, khokela umgodi we-arc kwicala le-groove uze uphule i-arc;

4. Ixesha lokuqala le-arc usebenzisa i-arc yokuqalisa ipleyiti okanye kwicala le-groove arc;

5. Gcina i-arc i-welding emfutshane;

6. Sebenzisa uqhagamshelo lwe-AC okanye lwe-DC.

Iimbonakalo

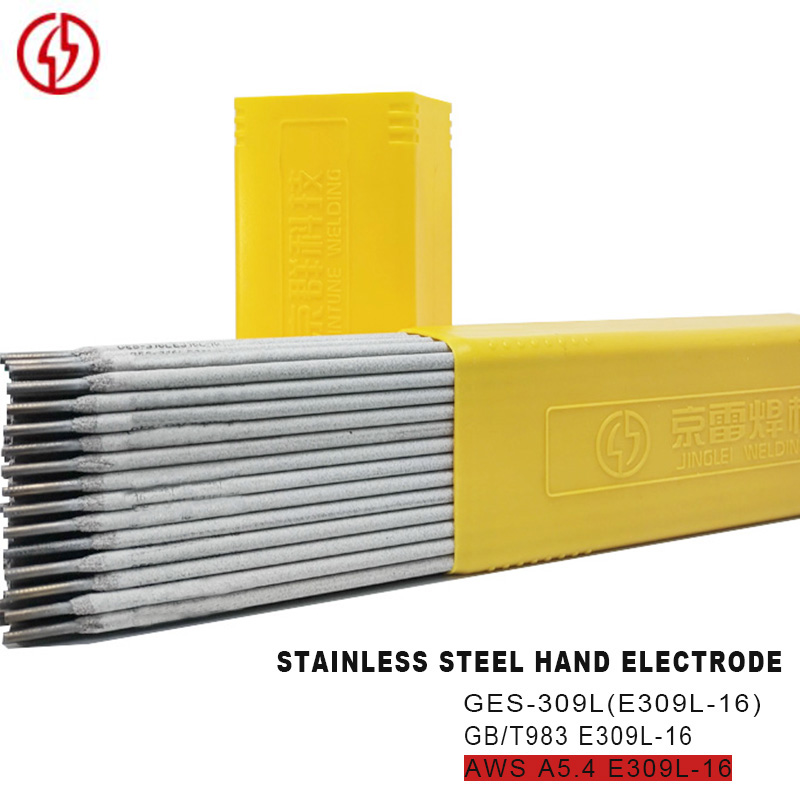

1. I-Titanium calcium i-electrode yensimbi engenasici, ukubunjwa okuphambili ngu-18% CR-8% Ni-6% Mn;

2. I-arc ezinzileyo, ukubunjwa okuhle, ama-ripples amahle, i-splashes embalwa, i-de-slagging elula, ukumelana nomlilo okulungileyo kwesikhumba samachiza, ukuxhathisa okulungileyo kwesisu.

3. Iimpawu ezizinzileyo zomatshini, izinga lokupasa kwe-X-reyi liphezulu.

E307-16with Grade (AWS A5.4),Stainless steel welding I-Electrode luhlobo olwahlukileyo lwentsimbi yokuwelda njenge-welding austenitic manganese kwi-carbon steel castings okanye i-forgings.

Zisetyenziswa kakhulu kwishishini lezicelo ezahlukeneyo kwaye zenziwe ngetekhnoloji ye-urbane kunye nenqanaba eliphezulu lemathiriyeli ekrwada eneempawu ezintsha, Ezi electrode zokuwelda ze-SS zisenokwenziwa ngokwesiko ngokunxulumene nobukhulu kunye nobukhulu bazo ngokweemfuno zabathengi.

Inkampani kunye neFactory

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T IMIGAQO | 0.20 | 4.5-7.5 | 1.20 | 17-20 | 44752.00 | 0.75 | 0.035 | 0.03 | 0.75 |

| I-AWS IMIGAQO | - | - | - | - | - | - | - | - | - |

| UMZEKELO IXABISO | 0.071 | 5.58 | 1.03 | 19.12 | 8.9 | 0.2 | 0.028 | 0.006 | 0.012 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | |||||||||

| GB/T IMIGAQO | 350 | 500 | - | - | 25 | |||||||||

| I-AWS IMIGAQO | - | - | - | - | - | |||||||||

| UMZEKELO IXABISO | - | 635 | - | - | 36 | |||||||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| UMBANE (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

IINKCUKACHA ZOKUPAKA:

| UKWAHLUKANA | UBUDE | PCS/1KG | Ubunzima/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

PHAWULA:

H / W: ukuwelda indawo ethe tye

O / W: phezu-intloko isikhundla welding

Amatyala aqhelekileyo

Isatifikethi

Ngokwesiqhelo ijolise kubathengi, kwaye yeyona nto sigxile kuyo ekubeni ingeyiyo kuphela yoyena mboneleli unoxanduva, othembekileyo nothembekileyo, kodwa neqabane labathengi bethu kwiBanga eliPhezulu eliPhezulu loMbhobho weSpeed Pipe Tube Mill iTitanium Duct Ukwenza uMatshini weMibhobho yoShishino loKuqulunqa uMbhobho Umatshini, Iimveliso ezenziwe ngexabiso lophawu. Sizimasa ngokuzimisela ukuvelisa nokuziphatha ngemfezeko, nangokuthanda abathengi basekhaya nakwamanye amazwe kushishino lwe-xxx.

IBanga eliphezuluUmatshini Wokwenza uMbhobho waseTshayina kunye noMshini Wokwenza uMbhobho wentsimbi, Ukuthatha ingcamango engundoqo "yokuba yiNgxelo". Siza kubuyisela uluntu kwiimveliso ezikumgangatho ophezulu kunye nenkonzo elungileyo. Siya kuqala ukuthatha inxaxheba kukhuphiswano lwamazwe ngamazwe ukuze sibe ngabavelisi abakumgangatho wokuqala wale mveliso ehlabathini.

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T IMIGAQO | 0.20 | 4.5-7.5 | 1.20 | 17-20 | 44752.00 | 0.75 | 0.035 | 0.03 | 0.75 |

| I-AWS IMIGAQO | - | - | - | - | - | - | - | - | - |

| UMZEKELO IXABISO | 0.071 | 5.58 | 1.03 | 19.12 | 8.9 | 0.2 | 0.028 | 0.006 | 0.012 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | |||||||||

| GB/T IMIGAQO | 350 | 500 | - | - | 25 | |||||||||

| I-AWS IMIGAQO | - | - | - | - | - | |||||||||

| UMZEKELO IXABISO | - | 635 | - | - | 36 | |||||||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| UMBANE (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

IINKCUKACHA ZOKUPAKA:

| UKWAHLUKANA | UBUDE | PCS/1KG | Ubunzima/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

PHAWULA:

H / W: ukuwelda indawo ethe tye

O / W: phezu-intloko isikhundla welding