Iintsimbi ezingenasici ze-TIG ER308L Ukudibanisa i-Welding

Isicelo

Ifanelekile kwi-petrochemical, isitya soxinzelelo, oomatshini bokutya, izixhobo zonyango kunye namanye amashishini, kunye neetanki zokugcina ubushushu obuphantsi, izitya kunye nezinye -196 ℃ izixhobo zokushisa eziphantsi, ezifana ne-SUS304L.

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T IMIGAQO | 0.03 | 1.0-2.5 | 0.3-0.65 | 19.5-22.0 | 9.0-11.0 | 0.75 | 0.03 | 0.03 | 0.75 | |

| I-AWS IMIGAQO | 0.03 | 1.0-2.5 | 0.3-0.65 | 19.5-22.0 | 9.0-11.0 | 0.75 | 0.03 | 0.03 | 0.75 | |

| UMZEKELO IXABISO | 0.017 | 2.06 | 0.54 | 19.88 | 9.72 | 0.01 | 0.018 | 0.007 | 0.01 | |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | ||||

| GB/T IMIGAQO | - | - | - | - | ||||

| I-AWS IMIGAQO | - | - | - | - | ||||

| UMZEKELO IXABISO | - | 595 | 75/-196 | 42 | ||||

Okukhethekileyo

Elona candelo liyi-20%Cr-9%Ni.

Isinyithi esinyibilikisiweyo sineempawu ezilungileyo zoomatshini kunye nokumelana nomhlwa, kunye nokuqina okugqwesileyo kwi -196 ℃.

I-arc ezinzileyo, ukubunjwa okuhle, ukuhamba kakuhle kwentsimbi etyhidiweyo, kunye nokusebenza kakuhle kwenkqubo ye-welding.

Bonisa iinkcukacha

Ukuzinza kwe-arc

Ubume obuhle

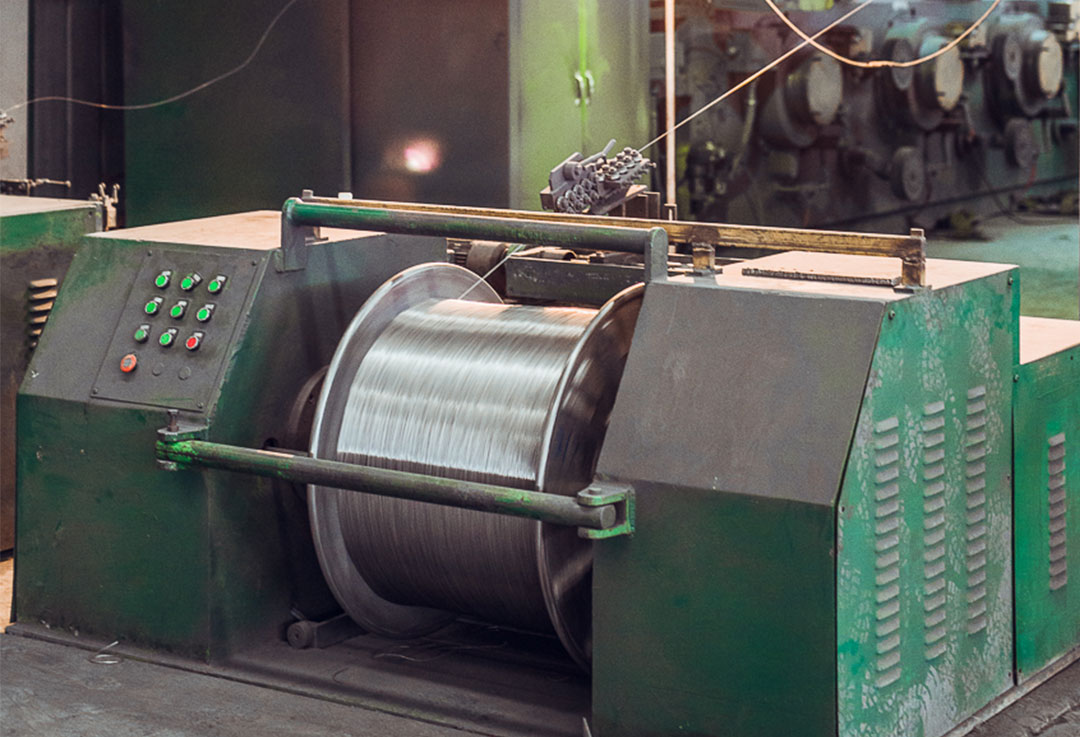

Umboniso wefioor wefektri

Ityala lesicelo

JU2000E jack-up yokomba rig

Ibhokisi yokutofa yokhuseleko

Okwenyani ukudubula kwefektri

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T IMIGAQO | 0.03 | 1.0-2.5 | 0.3-0.65 | 19.5-22.0 | 9.0-11.0 | 0.75 | 0.03 | 0.03 | 0.75 | |

| I-AWS IMIGAQO | 0.03 | 1.0-2.5 | 0.3-0.65 | 19.5-22.0 | 9.0-11.0 | 0.75 | 0.03 | 0.03 | 0.75 | |

| UMZEKELO IXABISO | 0.017 | 2.06 | 0.54 | 19.88 | 9.72 | 0.01 | 0.018 | 0.007 | 0.01 | |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | ||||

| GB/T IMIGAQO | - | - | - | - | ||||

| I-AWS IMIGAQO | - | - | - | - | ||||

| UMZEKELO IXABISO | - | 595 | 75/-196 | 42 | ||||

Bhala umyalezo wakho apha kwaye uwuthumele kuthi