I-Nickel alloys MIG ERNiCr-3 Uqhagamshelwano lweSoldering

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T IMIGAQO | 0.10 | 2.5-3.5 | 0.50 | 18.0-22.0 | ≥67 | - | 3.0 | 2.0-3.0 | - | - |

| I-AWS IMIGAQO | 0.10 | 2.5-3.5 | 0.50 | 18.0-22.0 | ≥67 | - | 3.0 | 2.0-3.0 | 0.03 | 0.02 |

| UMZEKELO IXABISO | 0.023 | 2.81 | 0.09 | 20.15 | 72.86 | 0.19 | 0.84 | 2.46 | 0.001 | 0.004 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | ||||

| GB/T IMIGAQO | - | - | - | - | ||||

| I-AWS IMIGAQO | - | 550 | - | - | ||||

| UMZEKELO IXABISO | - | 675 | 92/-196 | 42 | ||||

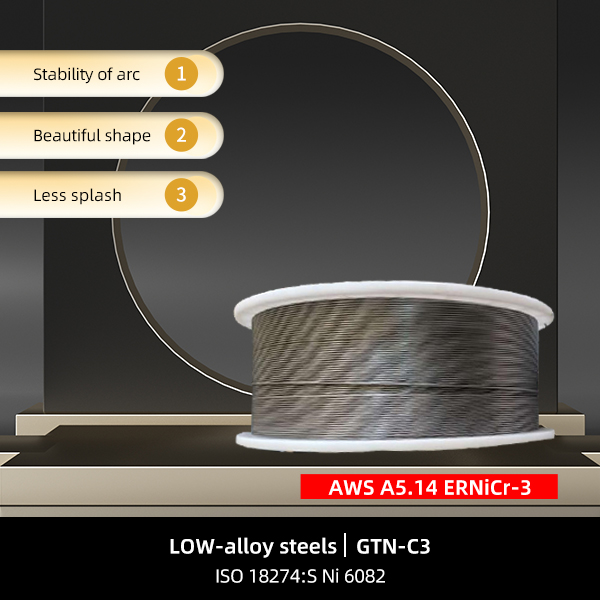

Ukuqulunqwa okuphambili yi-72Ni-20Cr-3Mn-2.5Nb + Ta, i-nickel-chromium alloy argon arc welding wire.

Isinyithi esinyibilikisiweyo sineempawu ezilungileyo zoomatshini kunye nokuxhathisa kakuhle kwi-corrosion yemingxuma kunye nokuhlwa kwemingxuma.

Ukutya okugudileyo kocingo, i-arc ezinzileyo, ukubunjwa okuhle, ukuhamba kakuhle kwentsimbi etyhidiweyo, ukuchaphaza okuncinci, kunye nokusebenza kakuhle kwenkqubo ye-welding.

-

85000 m3 Enkulu Kakhulu Ethylene Carrier (VLEC)

-

Iprojekthi yeLNG yaseCanada

Harbin yombane ezintathu umnyango CMT

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T IMIGAQO | 0.10 | 2.5-3.5 | 0.50 | 18.0-22.0 | ≥67 | - | 3.0 | 2.0-3.0 | - | - |

| I-AWS IMIGAQO | 0.10 | 2.5-3.5 | 0.50 | 18.0-22.0 | ≥67 | - | 3.0 | 2.0-3.0 | 0.03 | 0.02 |

| UMZEKELO IXABISO | 0.023 | 2.81 | 0.09 | 20.15 | 72.86 | 0.19 | 0.84 | 2.46 | 0.001 | 0.004 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | ||||

| GB/T IMIGAQO | - | - | - | - | ||||

| I-AWS IMIGAQO | - | 550 | - | - | ||||

| UMZEKELO IXABISO | - | 675 | 92/-196 | 42 | ||||

Bhala umyalezo wakho apha kwaye uwuthumele kuthi