I-Nickel alloys TIG ERNiCrMo-3 Izinto zokuthengisa

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T IMIGAQO | 0.10 | 0.50 | 0.50 | 20.0-23.0 | ≥58 | 8.0-10.0 | 5.0 | 3.0-4.2 | - | - |

| I-AWS IMIGAQO | 0.10 | 0.50 | 0.50 | 20.0-23.0 | ≥58 | 8.0-10.0 | 5.0 | 3.15-4.15 | 0.02 | 0.015 |

| UMZEKELO IXABISO | 0.006 | 0.15 | 0.12 | 22.02 | 64.84 | 8.75 | 0.18 | 3.49 | 0.001 | 0.001 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | ||||

| GB/T IMIGAQO | - | - | - | - | ||||

| I-AWS IMIGAQO | - | - | - | - | ||||

| UMZEKELO IXABISO | - | 790 | 159/-196 | 46 | ||||

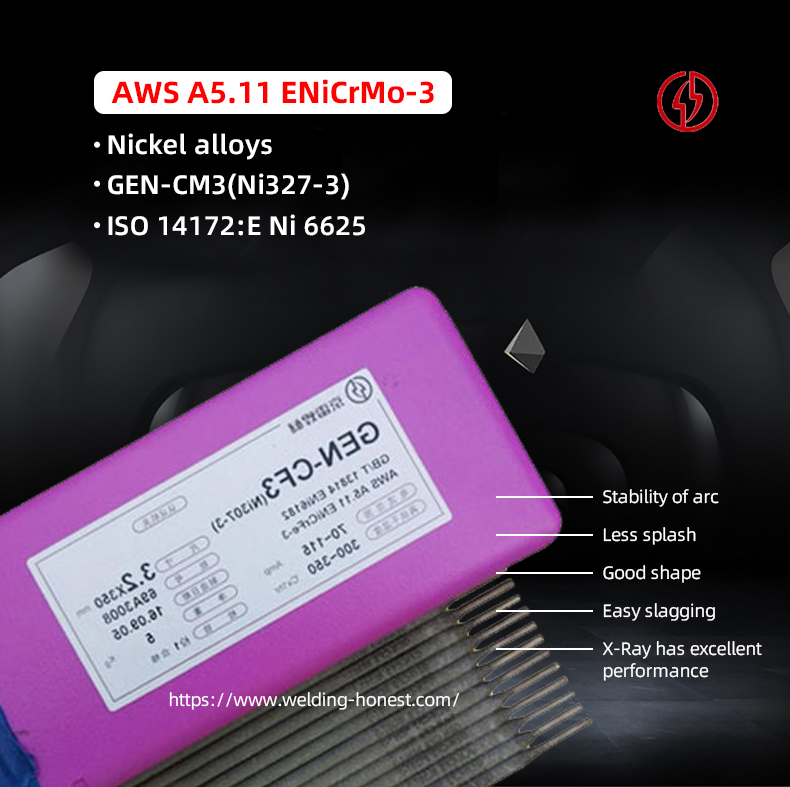

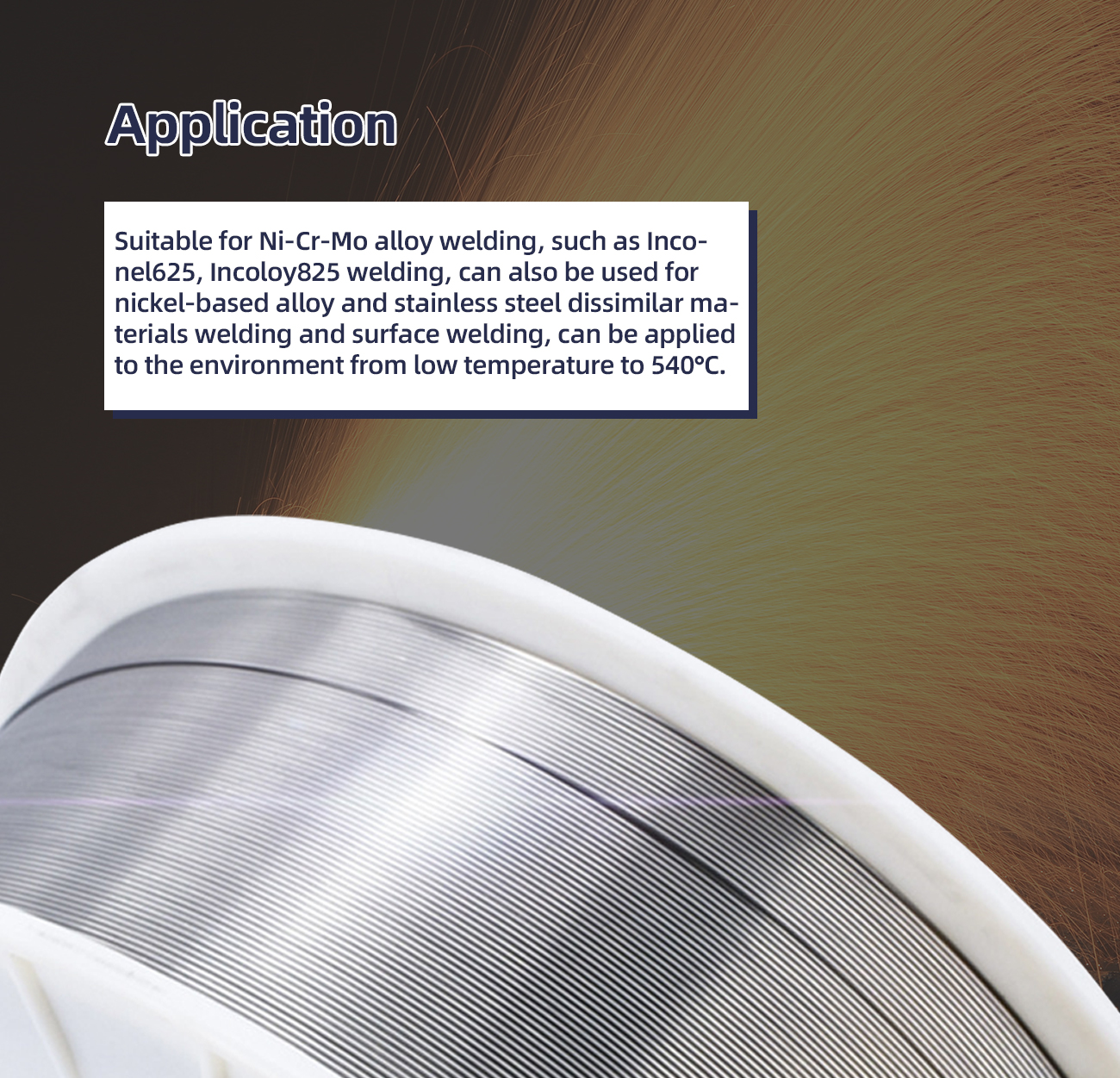

I-nickel-chromium-molybdenum i-nickel-base ye-alloy yegesi ye-welding wire, i-nominal composition yi-61%Ni-22%Cr-9%Mo-3.5%Nb+Ta.

Isinyithi esinyibilikisiweyo sineempawu ezilungileyo zoomatshini kunye nokuxhathisa kakuhle kwi-corrosion yemingxuma kunye nokuhlwa kwemingxuma.

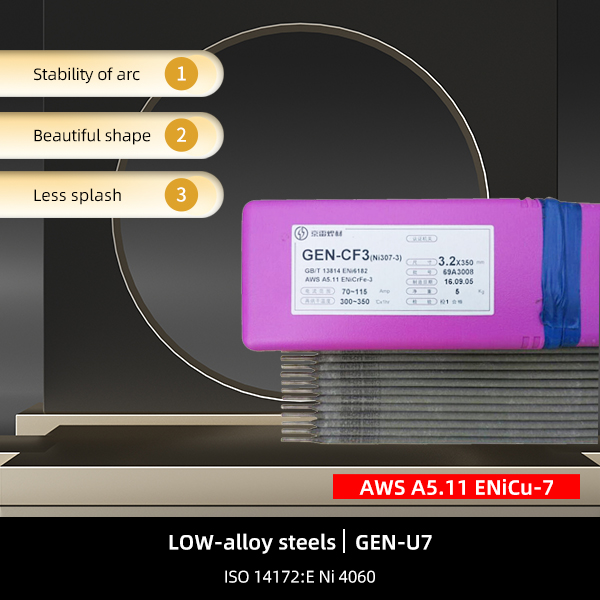

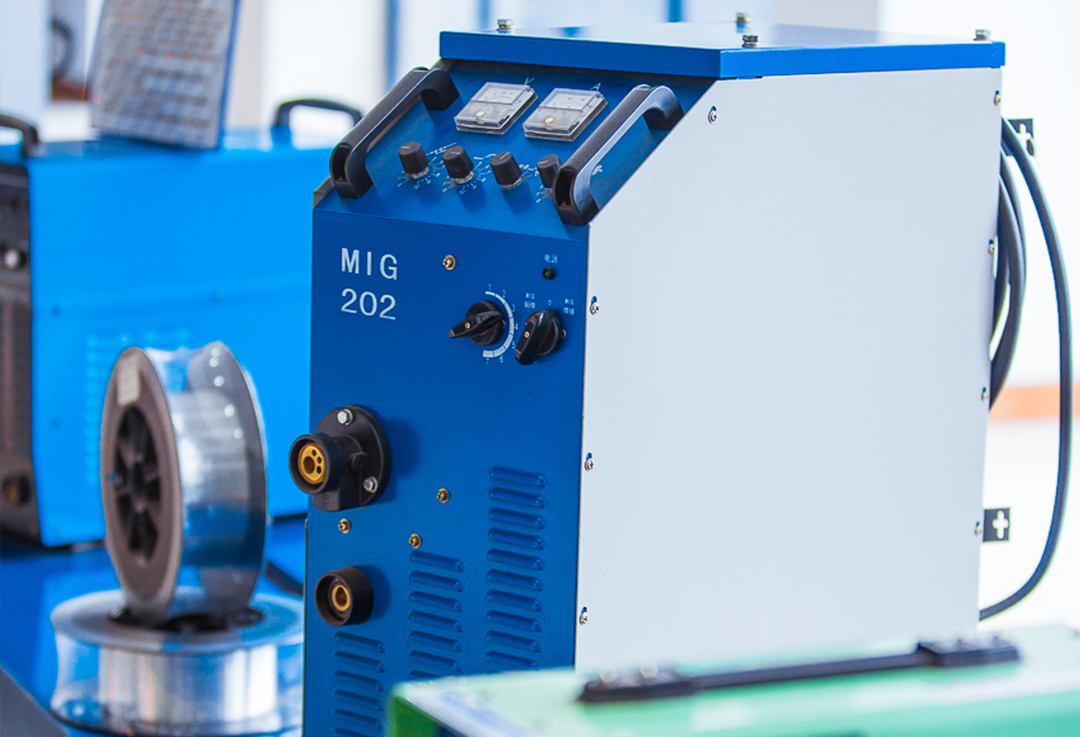

I-arc ezinzileyo, ukubunjwa okuhle, ukuhamba kakuhle kwentsimbi etyhidiweyo, kunye nokusebenza kakuhle kwenkqubo ye-welding.

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T IMIGAQO | 0.10 | 0.50 | 0.50 | 20.0-23.0 | ≥58 | 8.0-10.0 | 5.0 | 3.0-4.2 | - | - |

| I-AWS IMIGAQO | 0.10 | 0.50 | 0.50 | 20.0-23.0 | ≥58 | 8.0-10.0 | 5.0 | 3.15-4.15 | 0.02 | 0.015 |

| UMZEKELO IXABISO | 0.006 | 0.15 | 0.12 | 22.02 | 64.84 | 8.75 | 0.18 | 3.49 | 0.001 | 0.001 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | ||||

| GB/T IMIGAQO | - | - | - | - | ||||

| I-AWS IMIGAQO | - | - | - | - | ||||

| UMZEKELO IXABISO | - | 790 | 159/-196 | 46 | ||||

Bhala umyalezo wakho apha kwaye uwuthumele kuthi