Web: www.welding-honest.com Whatsapp:+86 13252436578

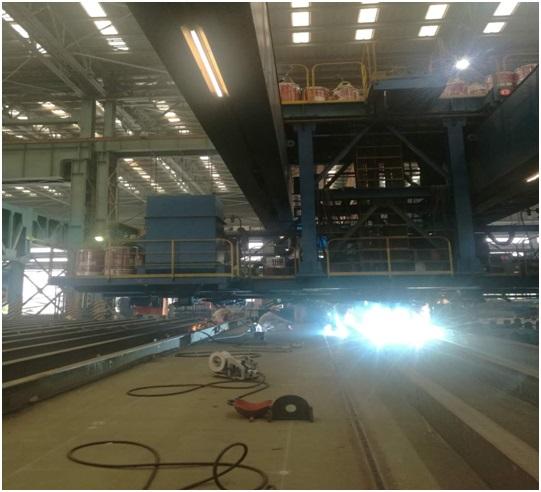

Kwimisebenzi ye-welding yokwakhiwa kweenqanawa, iibhulorho, izakhiwo zentsimbi kunye namanye amashishini, ngokuqhelekileyo kukho i-welding emide ye-right-angle welded, kunye ne-welding ezenzekelayo isetyenziswa kakhulu, kunye ne-welding trolleys, iingalo ze-welding ezizenzekelayo kunye neendlela ezisebenzayo ze-multi-electrode welding. Kwi-T-row multi-electrode welding, inkampani yethu yaphehlelela i-GFL-70C yentsimbi yomgubo wohlobo lwe-flux cored wire kunye ne-GCL-11G yesinyithi yohlobo lwe-welding wire, eyamkelwa ngabathengi abaninzi ngakumbi. Le ndlela yokudibanisa i-welding inesantya esiphezulu se-welding, i-primer egqwesileyo ye-zinc powder-resistant, kunye nokwakheka okuhle kwe-weld bead. Ukusebenza kwe-deposition yocingo lwangaphambili lwe-GCL-11G luphezulu ukuya kuma-97%, ngokukodwa ngenxa yobuninzi bentsimbi yokuzalisa, kunye nocingo olungasemva lwe-GFL-70C luqinisekisa ukubunjwa kwe-weld bead, kunye nesantya sokudibanisa sinokufikelela kwi-1000-1400mm. /min. Eyona nto ifanelekileyo kwi-welding flat kunye ne-flat fillet welding yezakhiwo ezahlukeneyo ezifana neenqanawa, iibhulorho, oomatshini, izithuthi kunye nezakhiwo zentsimbi.

Multi-electrode T-row high-speed kunye ne-welding esebenzayo

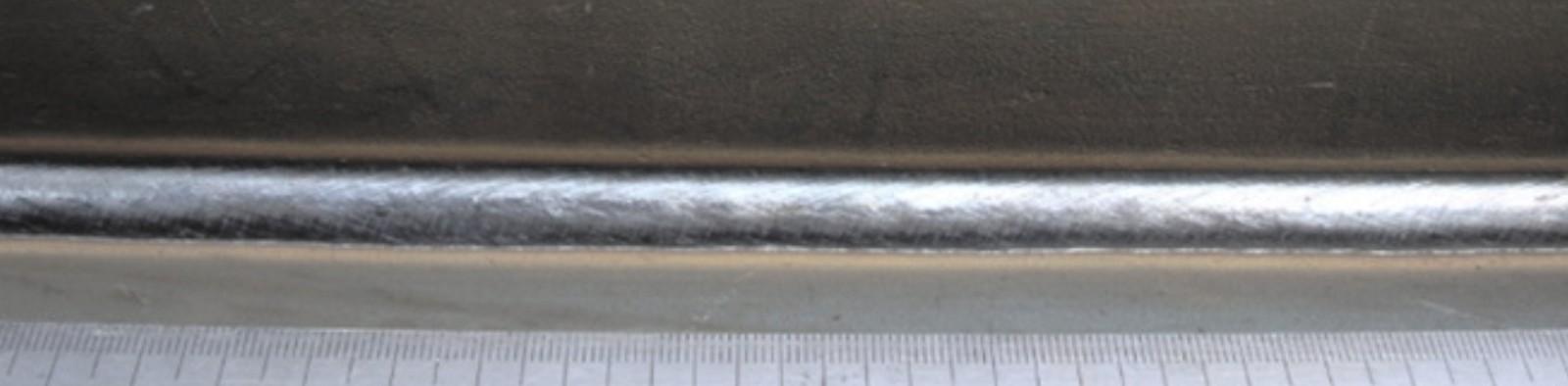

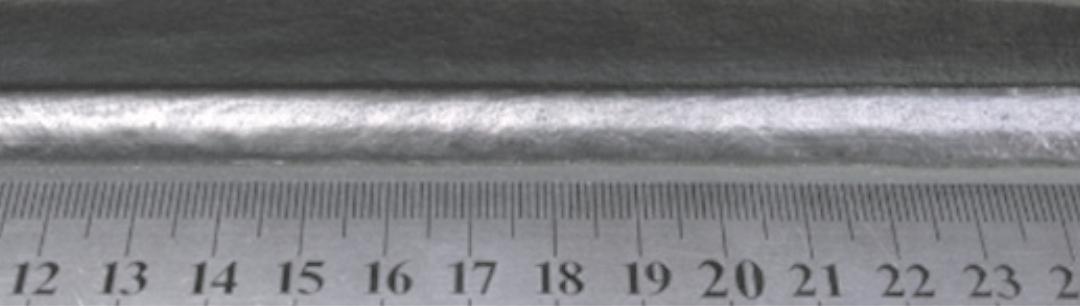

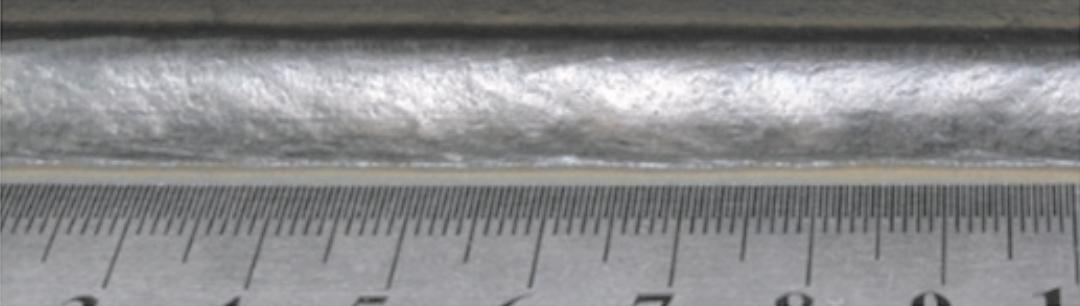

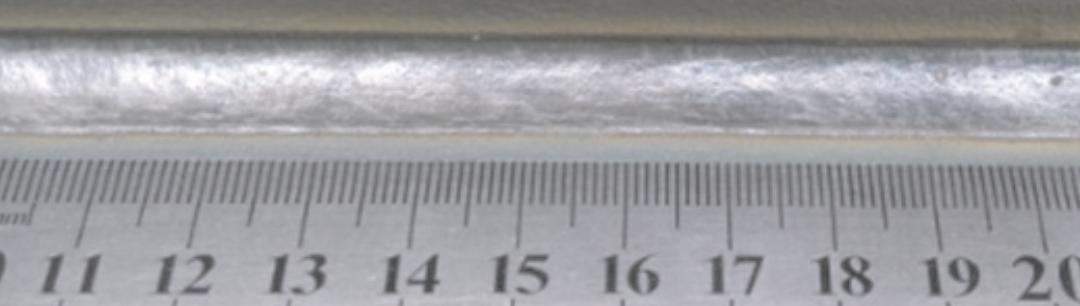

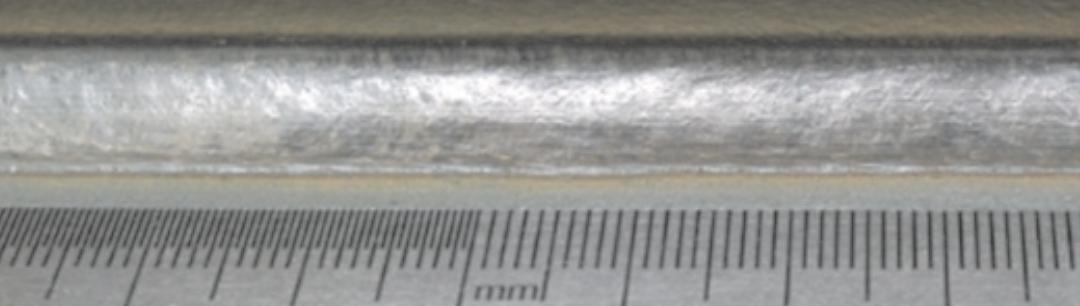

Ukubonakala kokususwa kwe-weld slag

Ngaphambi kokunciphisa

Emva kokucima

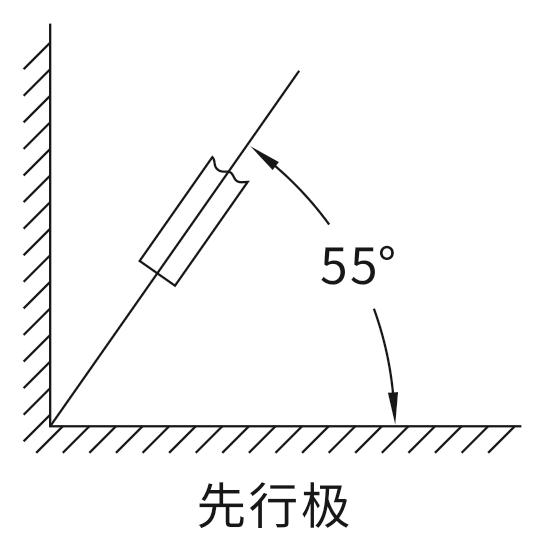

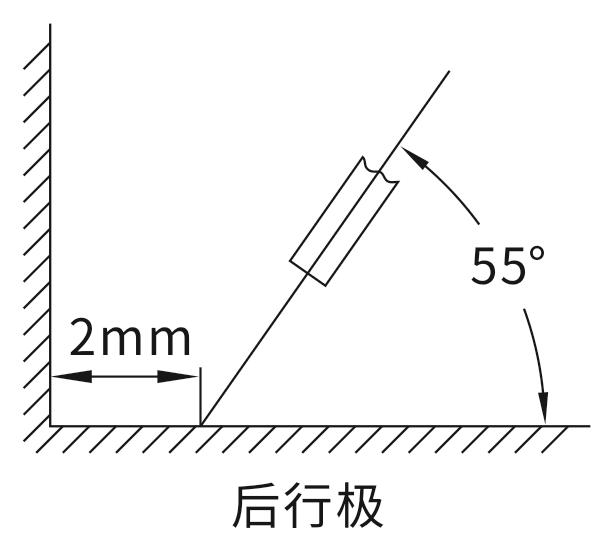

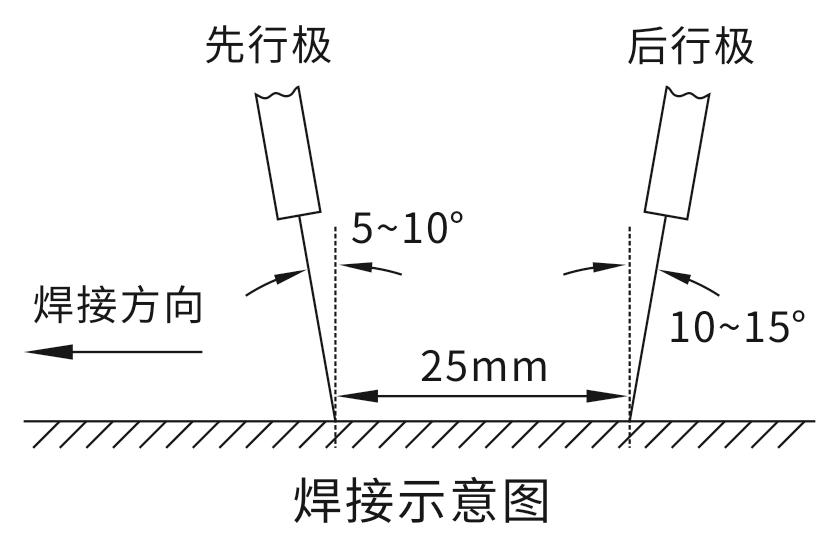

Eyona nto ibaluleke kakhulu yale ndlela ye-welding kukusebenza kwayo okuphezulu, i-multi-electrode welding ngaxeshanye, kwaye akukho mfuneko yokukhathazeka malunga nokuphazamiseka kwe-polarity kunye ne-magnetic field. Iqela ngalinye le-fillet welds lineeseti ezimbini zeetotshi ze-welding, kwaye iqela ngalinye linamacingo angaphambili nangasemva. Ucingo lwangaphambili lunokumelana okungcono kwe-porosity kwaye lusebenza njengesixa esikhulu sesinyithi sokuzalisa. Ucingo olungasemva lufuna kuphela ukuqinisekisa ukuba i-weld bead yenziwe yacaba, iyunifomu kwaye icocekile. Iimpawu ezikhoyo zohlobo lwe-iron powder flux cored wire, njengocingo lwangasemva lwale ndibaniselwano, lunokuhlangabezana nje neemfuno zemilo yayo ehambelanayo kunye nenkangeleko. I-angle yetotshi ye-welding kunye nohlengahlengiso lomgama wale ndlela ye-welding iboniswe kumzobo ongezantsi:

I-Hybrid yesantya esiphezulu kakhulu sokuwelda i-fillet:

Qaphela: Lungisa umgama phakathi kweengcingo zangaphambili nezingasemva ngokobushushu bechibi elinyibilikisiweyo ngexesha lokuwelda.

Le ndlela ye-welding inokufumana ulindelo olufunwayo lwe-welding ngokulungelelanisa iiparamitha ze-welding ezahlukeneyo. Ngokulungelelanisa i-welding yangoku, i-voltage, isantya se-welding, umgama wetotshi ye-welding, njl.

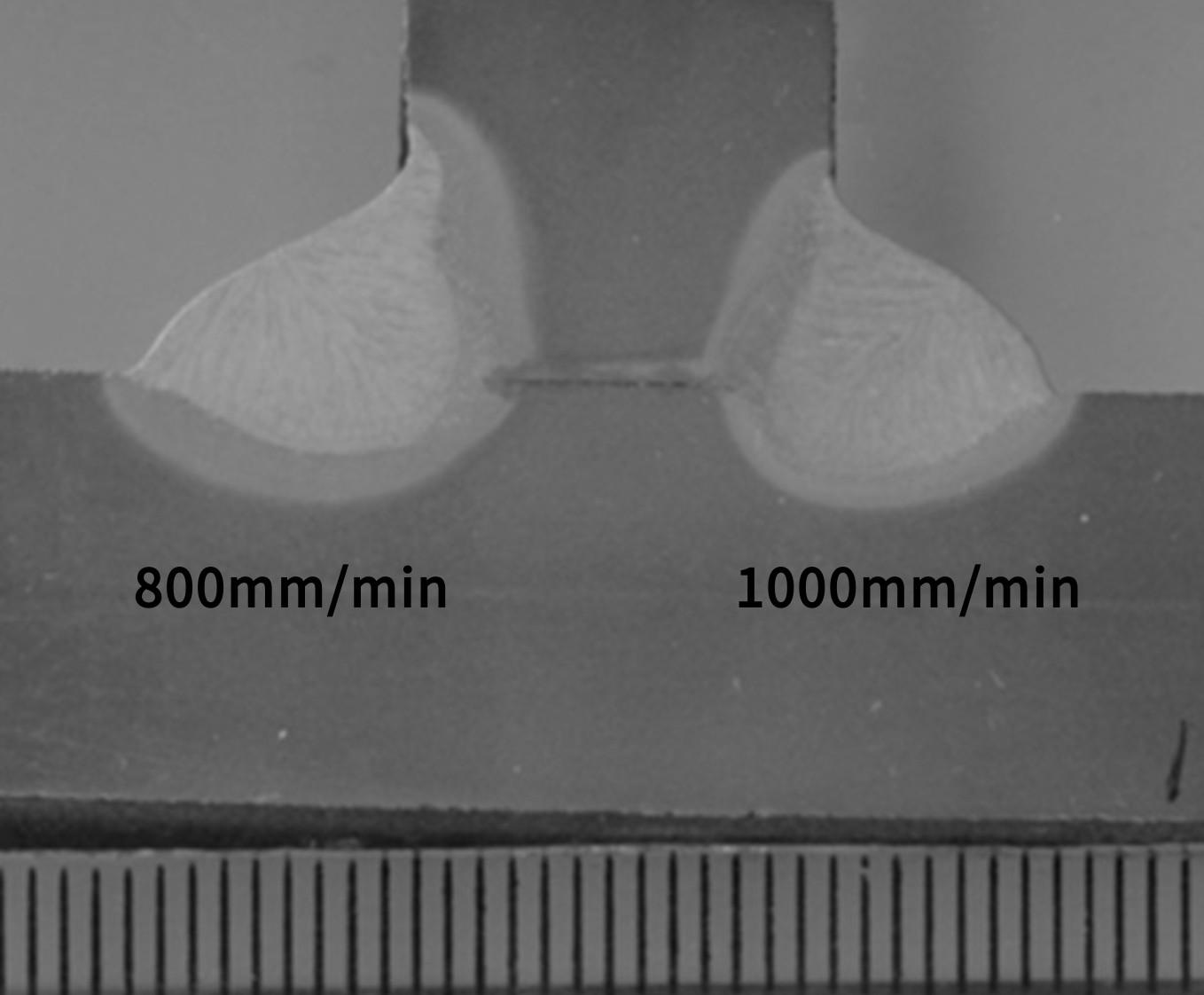

Umzekelo wokuwelda isantya esiphezulu kakhulu se-fillet 1

I-GCL-11G (i-electrode ephezulu)/GFL-70C (i-electrode yangasemva) 1.4mm:

| Okwangoku kunye ne-voltage | isantya welding mm/umz | Ubude bomlenze we-Solder |

| Uvulindlela 360A/32V Iklasi yokulandela i-360A / 38V Isithuba se-Electrode yi-25MM | 800 | 9-10 |

| 1000 | 7-8 |

| ubude bonyawo | 9.0 | ubude bonyawo | 7.0 | |

| I-Convexity | 0.4 | I-Convexity | 0.8 | |

| Ukungena | 2.0 | Ukungena | 2.2 |

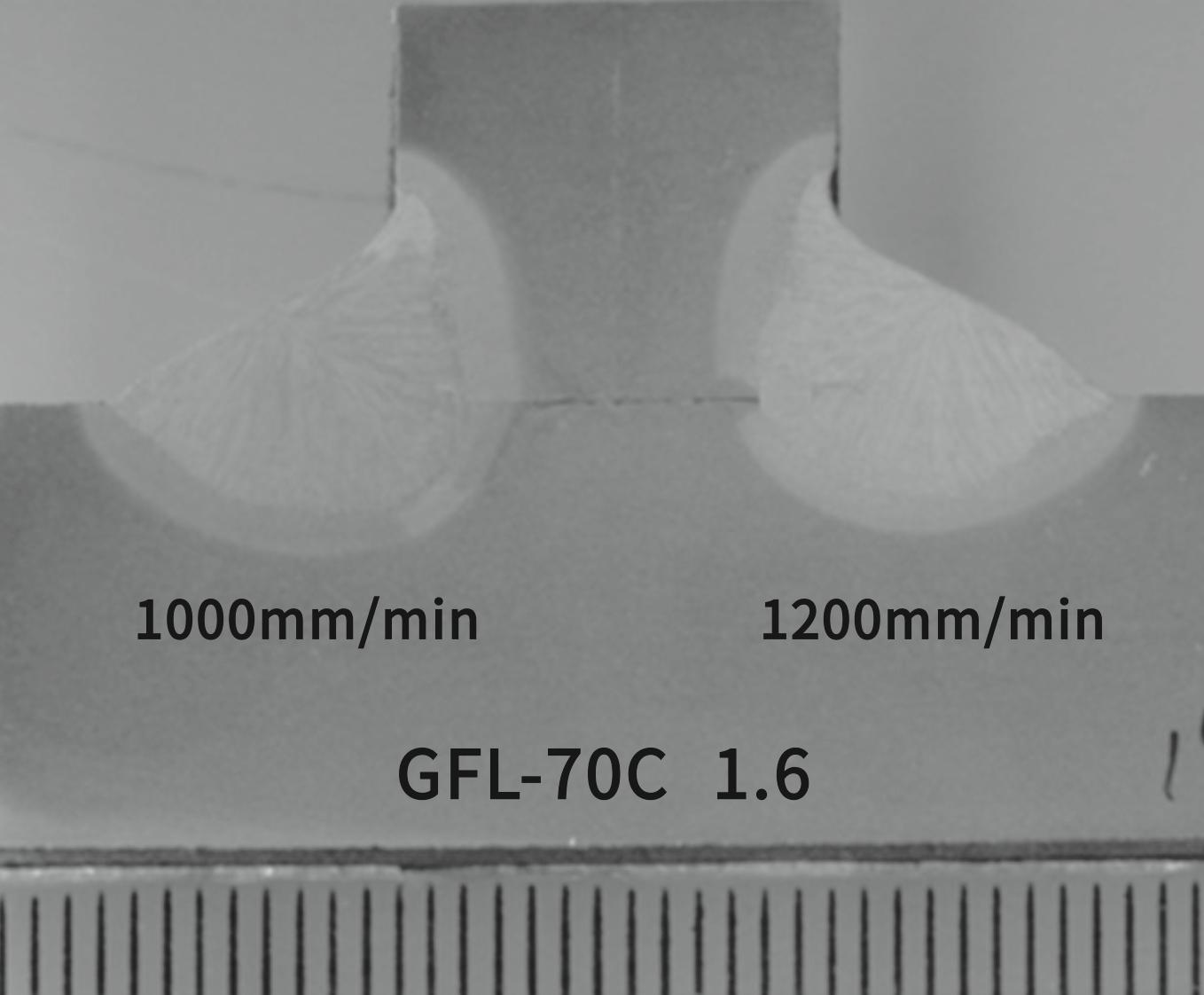

Umxube we-welding welding yesantya esiphezulu kakhulu 2

I-GCL-11G (i-electrode ephezulu)/GFL-70C (i-electrode yangasemva) 1.6mm:

| Okwangoku kunye ne-voltage | isantya welding mm/umz | Ubude bomlenze we-Solder |

| Uvulindlela 360A/32V Iklasi yokulandela i-360A / 38V Isithuba se-Electrode yi-25MM | 1000 | 8-9 |

| 1200 | 7-8 |

Ukubona ukungena

| ubude bonyawo | 8.0 |

| ubude bonyawo | 7.0 |

| I-Convexity | 0 | I-Convexity | 0.3 | |

| Ukungena | 2.4 | Ukungena | 2.7 |

I-GCL-11G + GFL-70C isincomo semeko ye-welding

| Udidi lwe-Welding | Inkcazo mm | iinkcukacha zokuwelding | isantya welding mm/umz | Ubungakanani bomlenze weSolder mm | Phawula | |

| Isilika yangaphambili | Isilika yangasemva | |||||

| indibaniselwano | 1.4 | 350-400A 32-36V | 320-380A 36-38V | 700- 1000 | 5-8 | Intambo yangaphambili yi-GCL-11G, isetyenziselwa ukugcwalisa, i-high current, i-voltage ephantsi; ucingo olungasemva yi-GFL-70C, i-voltage ephezulu, yangoku ephantsi |

| 1.6 | 360-420A 36-38V | 320-400A 36-38V | 1000- 14000 | 5-8 | ||

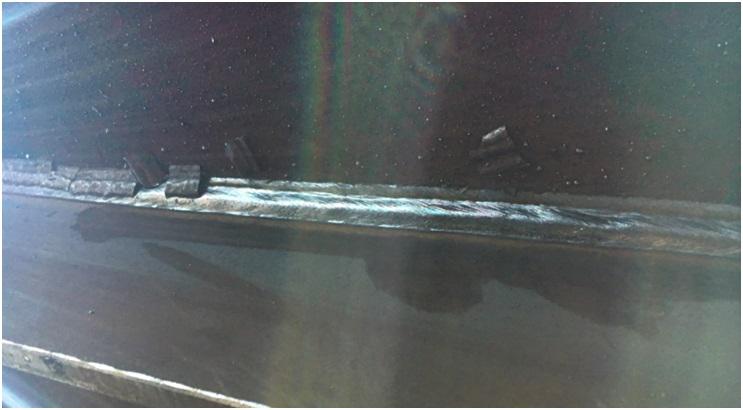

Enye: I-9-12mm ye-welding angle inokufumaneka ngokulungisa i-angle yetotshi ye-welding kunye nesantya se-welding. Weld bead njengoko kubonisiwe ngezantsi:

12mm i-angle yokuwelda enkulu

Kule ndlela ye-welding, nceda ulandele ezi ngcebiso zilandelayo kunye nezilumkiso

1. Coca inkunkuma emphezulu, umhlwa, amabala e-oyile, kunye neentsalela ze-oxidation, kungenjalo kunokubangela iipores okanye iziphene ezifana nokubumba kakubi.

2. Ubuninzi bomphunga wamanzi uya kuchaphazela umgangatho we-welding kwaye ubangele iipores. Ukuba ukufuma kuphezulu, kufuneka kususwe umswakama ofanelekileyo phambi kokuba kufakwe i-welding, kwaye i-welding yecala enye kufuneka igwenywe.

3. Ubukhulu befilimu yepeyinti ngokuqhelekileyo bulawulwa kwi-15-35um. Ukuba ubukhulu befilimu yepeyinti bukhulu kakhulu, buya kubangela ama-pores ngokulula, kwaye kufuneka bucoliswe ukuba kuyimfuneko.

4. Isantya sokuhamba kwegesi silawulwa kwi-20-25l / min, i-elongation eyomileyo ilawulwa malunga ne-20 ~ 25mm, kwaye isantya somoya sidlula i-2m / s, kwaye i-shelter eyimfuneko iyadingeka.

5. Xa i-welding idibene:

(1) Intambo yangaphambili ye-GCL-11G yepaneli yamandla e-welding ikhetha i-gear eqinile, kunye nocingo lwangasemva lwe-GFL-70C lwe-welding power panel lukhetha i-core gear;

(2) Xa i-welding fillet welds, iqela ngalinye le-quadrupoles lenziwa ngendlela yokujongana kunye neengcingo zangaphambili nangasemva.

Oku kungasentla kubhekiselele kuphela, nceda uzive ukhululekile ukundikhanyisela ukuba kukho nayiphi na into engafanelekanga.

More information send E-mail to export@welding-honest.com

Ixesha lokuposa: Dec-20-2022