Whatsapp:+8613252436578 E-mail:sale@welding-honest.com

1. ukuhlelwa

Ngokomlinganiselo wekhabhoni, intsimbi yekhabhoni inokwahlulwa ibe ngamacandelo amathathu alandelayo:

1) Intsimbi ye-carbon ephantsi C% ≤ 0.25

2) Intsimbi yekhabhoni ephakathi 0.25

3) Insimbi ephezulu ye-carbon C%> 0.6

Ikhathoni ephantsi

Phakathi kweKhabhoni

Ikhabhoni ephezulu

2. uhlalutyo weldability

Ubungakanani bomxholo wekhabhoni yireferensi ebalulekileyo yokuphuhliswa kweenkqubo ze-welding. Njengoko umxholo wekhabhoni ukhula, amandla kunye nobunzima banda, ngelixa iplastiki kunye nokuqina kuncipha, ngelixa uxinzelelo lukhula. Ukuthetha ngokufanelekileyo, i-carbon content content, i-weldability engcono, ngoko ke, umxholo wekhabhoni ngumgangatho wokugweba ubunzima be-carbon steel welding, kunye neenkqubo ezahlukeneyo ze-welding kufuneka zamkelwe kumxholo wekhabhoni.

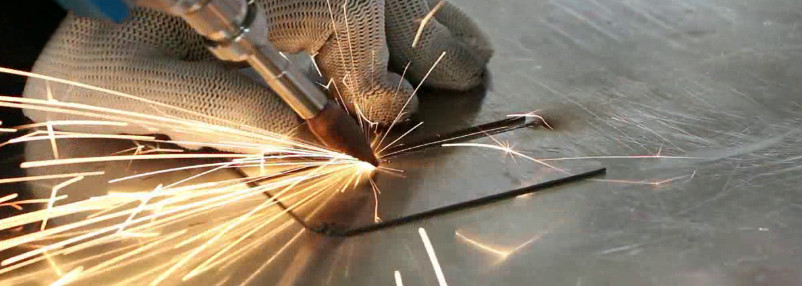

3. Inkqubo ye-Welding

Ukukhethwa kwezixhobo ze-carbon steel welding kulandela umgaqo "wamandla alinganayo"

1. Intsimbi yekhabhoni ephantsi (eyaziwa ngokuba yintsimbi ethambileyo)

Amabakala ensimbi aqhelekileyo afana ne-Q235 (eyangaphambili eyaziwa ngokuba yintsimbi ye-A3), i-Q255, njl., Ngokuqhelekileyo ayithathi amanyathelo akhethekileyo xa i-welding, i-preheating okanye i-postheating.

2. Intsimbi yekhabhoni ephakathi

Intsimbi esetyenziswa ngokuqhelekileyo njenge-30 #, 45 #, njl., 45 # yimpahla yokuvelisa ii-saw blades kunye neefayile, kungcono ukusebenzisa izinto ezisezantsi ze-hydrogen kunye nokumelana nokuqhekeka okulungileyo, ukutshisa i-100-200 °C; Ukuba akulungelekanga ukutshisa, i-Cr-Ni austenitic i-stainless steel welding material ingakhethwa.

3. Intsimbi yekhabhoni ephezulu

Amanqanaba entsimbi asetyenziswa ngokuqhelekileyo njenge60Si2Mn, T8, T10 njalo njalo. I-60Si2Mn yintsimbi yasentwasahlobo eqhelekileyo, ayiqhubeki nonyango lwe-welding, esetyenziswa kakhulu njenge-welding kwakhona, kufuneka ibe yi-250-350 ° C yokufudumeza kwangaphambili, i-welding kufuneka ibethelwe ngehamile ukuze kupheliswe uxinzelelo, kunye ne-650 ° C emva konyango lobushushu. khetha Cr-Ni austenitic steel stainless welding materials

Okwesine, i-electrode yesandla yentsimbi ethambileyo iyimfuneko ngokubanzi:

Electrode ukomisa iqondo lobushushu

| Into | Uhlobo lwesikhumba | Imveliso | Ubushushu | Ixesha |

| Intsimbi yekhabhoni ephantsi kunye nentsimbi enamandla kakhulu | Uhlobo lwe-hydrogen ephantsi | E7016, E7048, E7015, E7015-G | 300-350℃ | 60min |

| E7015,E8015-G,E9016-G,E9015-D1,E10015-D2,E12015-G | 330-380℃ | |||

| Ukuqina okuphezulu kunye nohlobo oluphantsi lwe-hydrogen | E7016-G,E7015-G,E8015-G,E9015-G,E10015-G | 350-380℃ | 60min | |

| Umgubo wentsimbi ephantsi uhlobo lwe-hydrogen | E7018、E7018-1 | 300-350℃ | 60min | |

| E8018-G,E918-G,E9018-M、E10018-D2、E10018M、E11018-G、E11018M、E12018-G | 350-380℃ | 60min |

2. Umswakama, ioli, i-rust, njl. ebusweni bezinto ezisisiseko kufuneka zisuswe

3. Sebenzisa indlela yokubuyela ngasemva ukuwelda ukuphepha i-stomata kwindawo yokuqala

I-arc i-welding emfutshane kufuneka isetyenziswe, njengemicu ye-oscillating, kunye ne-oscillation amplitude akufanele idlule amaxesha ama-3 ububanzi bocingo.

Ixesha lokuposa: Oct-13-2022