Intsimbi ye-G115 luhlobo olutsha lwezinto zentsimbi ezikwaziyo ukumelana nobushushu kunye nokusebenza okubalaseleyo kobushushu obuphezulu ngokuzimeleyo eziphuhliswe e-China, esetyenziswa ikakhulu ekwenzeni imibhobho engqindilili enobubanzi obukhulu kunye nezinye iindawo ezikwaziyo ukumelana nobushushu kwi-630 ~ 650 °C. , kwaye iyona nto ibalulekileyo ekuphuculeni umgangatho osebenzayo weeyunithi zamandla okushisa amalahle.

Ukususela ngo-2016, siye saphuhlisa ngokuqhubekayo kunye nokuphucula izinto ezisetyenziswayo ze-welding ze-G115 zensimbi, kwaye sisebenze ngokusondeleyo kunye namaziko ophando ahlukeneyo kunye nabasebenzisi kule nkqubo, kwaye siphumelele iziphumo ezivelisa iziqhamo. Ngo-Agasti 2020, wancedisa ngempumelelo ekubambeni "i-G115 i-Heat-resistant Steel Welding Process Seminar" e-Kunshan, emva koko imizuzu yentlanganiso yaqulunqwa (jonga umfanekiso ongezantsi), kunye namaxwebhu abalulekileyo okukhokela njenge "G115 Steel Welding. Inkqubo yoVavanyo lweNtsebenzo yeZalathi eziQinisekisiweyo" kunye ne "G115 Steel Welding Process Route kunye neKey Parameters" zaqulunqwa.

Emva kokucacisa iimfuno zokusebenza kunye neenkcukacha zeparameter kwintlanganiso, saqhubeka sityala imali engakumbi kuphuhliso, kwaye siphuhlise uluhlu olupheleleyo lwezixhobo ze-welding ze-G115 kunye nenkqubo ye-welding egqwesileyo (i-electrode kunye ne-TIG ye-welding wire inokuhlangabezana ne-welding full position), ezinzile. ukusebenza, nokuhlangabezana neemfuno zezalathisi zokusebenza ezahlukeneyo ezimiselwe yintlanganiso. Iimodeli ezithile kunye neempawu ziboniswe kwiThebhile 1 ngezantsi.

Uluhlu lwezinto ezisetyenziswayo ze-welding ze-G115 zentsimbi

| INTO | IGAMA LEMVELISO | UMBONO |

| intonga yeManuwali | IGER-93 | Uhlobo lwe-electrode yocingo olungundoqo, icandelo eliphambili yi-9% Cr-3% W-3% Co-Cu-V-Nb-B, ukuchasana kwempembelelo ezinzileyo kwiqondo lokushisa, kwaye kukho umda. |

| GTAW ucingo | GTR-W93 | Izithako eziphambili zifana nalapha ngasentla, kwi-priming, ukusebenza okuzinzileyo kunye nokusebenza kakuhle |

| Argon free ukukhusela umvaiintonga ze-GTWA | GTR-E93 | I-argon ye-arc welding wire, icala elingasemva linokukhululeka ekuzalisweni kwe-argon, ukubunjwa kwamacala amabini kuhle kakhulu. |

| SAW ucingo | GWR-W93 | I-weld bead yenziwe kakuhle, izinga lokufumana isiphene liphezulu, kwaye ukusebenza kwempembelelo kuzinzile. |

| Flux | GXR-93 |

Ngexesha elifanayo, siqhuba ngokunyanisekileyo utshintshiselwano lobugcisa, uvavanyo lwentsebenzo ye-welding kunye nenkqubo yokutshintshiselana kunye neeyunithi ezahlukeneyo zabasebenzisi, kwaye sifune amathuba ovavanyo lwe-tube ye-G115 ukuqinisekisa ngokupheleleyo ukuthotyelwa kwe-welding consumables kwinkqubo yangempela.

NgoFebruwari 2022, i-Guangdong Thermal Power Welding Company yavavanya intonga yethu yentsimbi ye-G115 ye-welding (igama lemveliso: GER-93) ye-115mm yenkqubo yokudibanisa umbhobho.

Oku kulandelayo ngumboniso omfutshane wenkqubo yovavanyo:

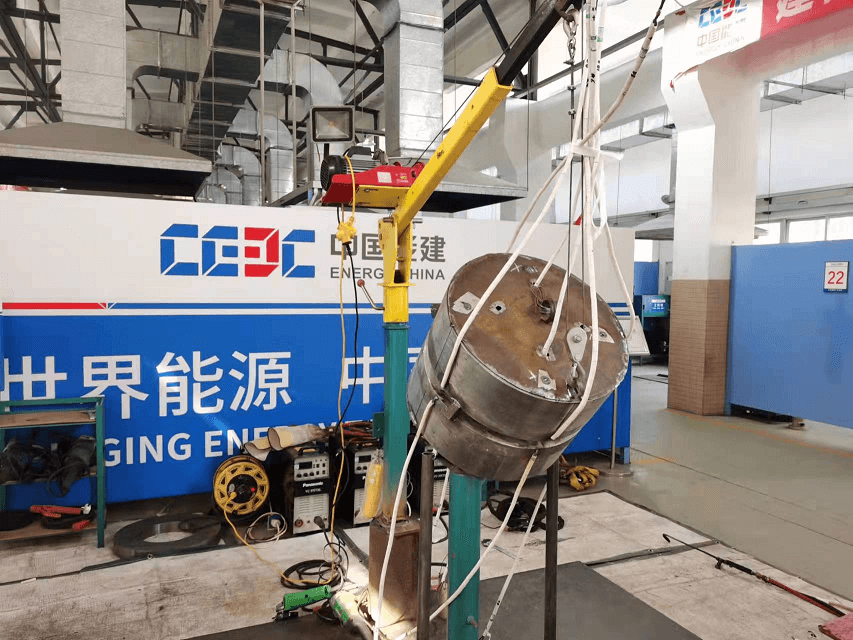

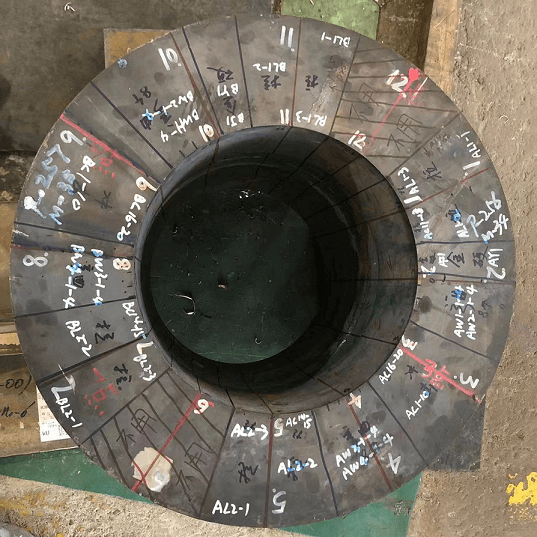

Umzobo we-1 yisithombe sokuqala sokufakelwa kombhobho kolu vavanyo, kunye nobukhulu bokulinganisa umbhobho: φ530 × 115mm.

Ukulungiswa kwezixhobo zombhobho ngaphambi kwe-welding

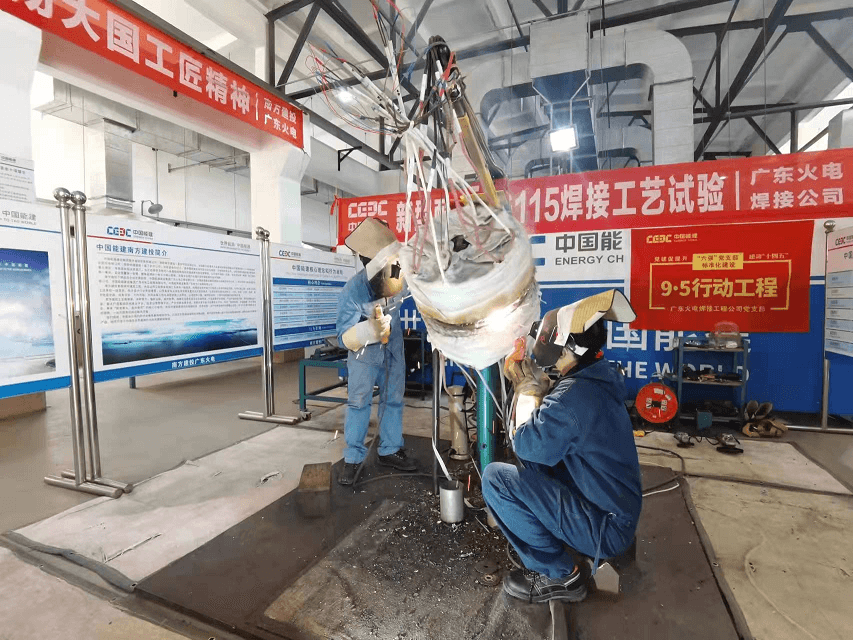

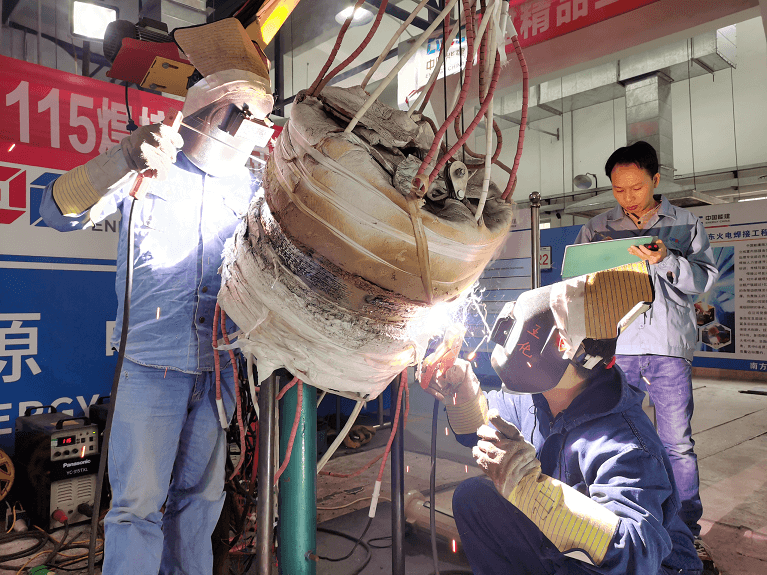

Amanani 2 kunye ne-3 yimizekelo yeefoto zenkqubo ye-welding, indawo ye-welding yi-6G, kwaye iiparitha zenkqubo zibhalwe ngokungqongqo kwaye zilawulwa ngabasebenzi bayo benkqubo.

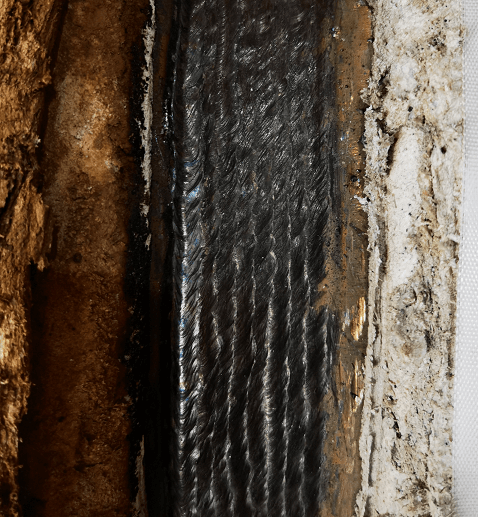

Umzobo 4 kunye noMzobo 5 ubonisa i-weld emva kwe-welding, kunokubonwa ukuba i-weld bead isicaba, i-pool etyhidiweyo ifanelekile, kwaye i-corrugation ilungile, ebonisa ukuba izinto ezisetyenziswayo ze-welding zinemisebenzi emihle yokusebenza kwe-welding.

Umzobo wesi-6 ubonisa ubude obusele be-electrode yethu emva kwe-welding, kunokubonwa ukuba intsalela emva kwe-welding ingaphantsi, ibonisa ukumelana nomlilo okulungileyo kwe-electrode, kwimeko yobushushu obuphezulu be-welding inokuhlala igcina i-arc kunye ne-molt pool state. , izinga lokusetyenziswa kwe-electrode enye liphezulu, ukuphepha inkunkuma.

Ubushushu obulandelayo bonyango lobushushu yi-775 °C, iqondo lobushushu elingaguqukiyo kwiiyure ezili-12, uMzobo 7 yifoto ecwangcisiweyo yesampulu yovavanyo ngalunye.

Iziphumo zovavanyo zesampulu nganye yovavanyo lwe-welding welding ziye zakhululwa, ukusebenza kwe-tensile kugqwesileyo, kwaye iipleyiti ezinqabileyo ziphukile kwindawo yesiseko sesinyithi; Umsebenzi wokufunxa impembelelo ulungile kwaye kukho umda othile; Ixabiso lobulukhuni likumgca; Iziqwenga ezigobileyo ezithathiweyo azinazo iintanda kunye nezinye iziphene. Iziphumo xa zizonke ziyanelisa kwaye ziyahlangabezana neemfuno ezilindelekileyo zovavanyo.

Ukuba ufuna ulwazi oluthe kratya, nceda uzive ukhululekile ukusibiza!

Siza kuqhubeka nokusebenza kwinkqubo yokwenziwa kwendawo yezinto ezityiwayo ze-welding eziphezulu. Ukufaka isandla kwiqhinga lesizwe lamandla, ugcino lwamandla kunye nokunciphisa ukukhutshwa kwegesi ekhutshwayo, ndiyathemba ukuba ndiza kuba nethuba lokufunda kumashishini acinga ngokufanayo kunye nabahlobo, kwaye sisebenzisane!

Ixesha lokuposa: Dec-01-2022