Ngo-2010, i-POSCO yaseMzantsi Korea, i-Daewoo Shipbuilding kunye nemibutho emihlanu emikhulu yehlabathi yaqala iprojekthi "yophuhliso oludibeneyo lwentsimbi ye-manganese ephezulu kunye nezixhobo zokuwelda ubushushu obuphantsi kakhulu", kwaye yaphunyezwa ukuveliswa kwentsimbi ephezulu yemanganese kwiitanki zokugcina i-LNG. 2015. NgoJuni 2022, ukutyhutyha i-bottleneck yobugcisa, i-South Korea ye-Daewoo Shipbuilding & Marine Engineering (DSME) kunye ne-POSCO iya kubamba okokuqala emhlabeni ukufaka iitanki ze-high-manganese zentsimbi ye-LNG yokugcina i-fuel kwi-LNG-powered i-LNG-powered crude carriers. (VLCCs) Umsitho, kwaye yathi iphuhlise ubugcisa bokwenza itanki yamafutha ukusuka ekulungisweni kwentsimbi kwangaphambili ukuya kwiwelding kunye nokwenza.

1. Yintoni intsimbi ephezulu yemanganese?

Intsimbi ephezulu yemanganese yeetanki zokugcina i-LNG yintsimbi yealloyi enomxholo wemanganese phakathi kwe-22-25%, enokumelana kakuhle nobushushu obuphantsi kunye nokumelana nokunxiba okuphezulu, okucaca ngakumbi kunezixhobo zetanki zokugcina ze-LNG Isithandwa esitsha setanki yokugcina i-LNG. izinto eziye zanikelwa nguMzantsi Korea kuphando nophuhliso iminyaka engaphezu kweshumi.

2.Uhlalutyo olufutshane lweentlobo zentsimbi kunye neenzuzo zabo kunye nokungonakali kwiitanki zokugcina i-LNG Izinto zethu zokudibanisa i-welding zinokuhlangabezana nezi mfuno zingqongqo: Ekubeni iitanki ezinkulu zokugcina i-LNG ze-fuel ziyizona zixhobo eziphambili zeenqanawa ze-fuel-powered-friendly and the whole industry chain LNG, imigangatho yobugcisa ingqongqo ngokugqithisileyo kwaye ixabiso liyabiza. I-LNG idla ngokugcinwa kwaye ihanjiswe phantsi kwemekobume yobushushu obuphantsi kakhulu obuyi-163°C. "IKhowudi yamazwe ngamazwe yoLwakhiwo kunye neZixhobo zeeNqanawa ezithwala iiGasi eziNyenziwe ngoBuninzi" zibizwa ngokuba yi "IGC Code". Izinto ezine ezisezantsi zokushisa ezingasetyenziselwa ukwakhiwa kwe-LNG ziquka: i-aluminium alloy steel, i-Austria Tensitic stainless steel, i-austenitic Fe-Ni i-alloy steel (eyaziwa nangokuthi i-Invar steel) kunye ne-9% yensimbi ye-Ni (jonga iThebhile 1 ngeenkcukacha), ngelixa i-9% ye-Ni steel yeyona nto isetyenziswa kakhulu kwaye isetyenziswa ngokubanzi kwiitanki zokugcina amafutha e-LNG. Kodwa izinto ezingeloncedo kukuba ixabiso lisephezulu, iinkqubo zokucubungula zinzima, amandla aphantsi, kwaye umxholo we-nickel kwimveliso uphezulu. Kwiminyaka yakutshanje, ixabiso le-nickel liye laqhubeka likhula, kwaye ixabiso lemveliso liye landa kakhulu.

Izinto ezi-4 ze-cryogenic ezinokuthi zisetyenziswe kulwakhiwo lwe-LNG phantsi kwe "IGC Code"

| Ubuncinci boyilo lobushushu | Iintlobo zetsimbi eziphambili kunye nonyango lokushisa | Ubushushu bovavanyo lwempembelelo |

| -165℃ | 9%Ni intsimbi ye-NNT okanye i-QT | -196℃ |

| i-austenitic stainless steel - 304, 304L, 316/316L, 321 kunye ne-347 isisombululo esiphathwayo | -196℃ | |

| I-aluminiyam ialloy - 5083 i-annealed | NO | |

| i-austenitic iron-nickel alloy (36%Ni) |

Ukuthelekiswa kwamandla phakathi kwezinto ezisetyenziswa ngokuqhelekileyo ze-LNG kunye nentsimbi entsha ye-manganese ephezulu

| Into | Ngokuqhelekileyo i-alloy | intsimbi ephezulu yemanganese | ||||

| 9% Ni intsimbi | 304 SS | Alu 5083-O | Invar intsimbi | MC | ||

| Izinto ezisisiseko | Ukuqulunqwa kwemichiza | Fe-9Ni | Fe-18.5Cr-9.25Ni | I-Al-4.5Mg | Fe-36Ni | M CH indoda |

| Microstructure | α1 (+Y) | γ (FCC) | FCC | FCC | FCC | |

| Unikeze AmandlaMpa | ≥585 | ≥205 | 124-200 | 230-350 | ≥400 | |

| Tensile strength Mpa | 690-825 | ≥515 | 276-352 | 400-500 | 800-970 | |

| -196℃ImpembeleloJ | ≥41 | ≥41 | NO | NO | ≥41 | |

| IiWeldments | ukuwelda izinto ezityiwayo | Inconal | Uhlobo308 | ER5356 | - | FCA,SA,GTA |

| Unikeze AmandlaMpa | - | - | - | - | ≥400 | |

| Tensile strengthMpa | ≥690 | ≥550 | - | - | ≥660 | |

| -196℃ImpembeleloJ | ≥27 | ≥27 | - | - | 27 | |

I-Ultra-low-low high-manganese steel, edibanisa amandla aphezulu, ukuqina okuphezulu, kunye neendleko eziphantsi, inethemba elibanzi kakhulu lesicelo kwixesha elizayo itanki yokugcina amafutha e-LNG kunye nokhuseleko lokusingqongileyo iimarike zetanki zokugcina amafutha ezifana ne-ammonia yolwelo, i-hydrogen engamanzi, kunye ne-methanol.

Ukuqulunqwa kunye neemfuno zokusebenza zentsimbi ephezulu yemanganese

Ukwakhiwa kwemichiza (i-ASTM Draft)

|

| C | Mn | p | s | Cr | Cu |

| % | 0.35-0.55 | 22.5-25.5 | <0.03 | <0.01 | 3.0-4.0 | 0.3-0.7 |

Indlela yokuziphatha koomatshini

● Ubume bekristale: iletisi yetyhubhiki ephakathi kobuso (γ-Fe)

● Ubushushu obuvumelekileyo>-196℃

● Amandla esivuno>400MPa (58ksi)

● Amandla okuqina: 800~970MPa (116-141ksi)

● Uvavanyo lwempembelelo ye-Charpy V-notch >41J ku -196℃(-320℉)

Intshayelelo yenkampani yethu ephezulu yemanganese yentsimbi ehambelana nezinto ezityiwayo ze-welding

Kwiminyaka yakutshanje, siye sazinikela kuphando kunye nophuhliso lwe-high-manganese yentsimbi ehambelana ne-welding consumables kwi-tank yokugcina i-LNG, kunye nokuphuhliswa ngempumelelo kwe-welding consumables ezinokuthi zihambelane neempawu zesiseko sentsimbi ye-manganese ephezulu kwiitanki zokugcina i-LNG. Iipropati ezithile zibonisiwe kwiThebhile 2.

Iipropathi zobutshini zentsimbi ephezulu yemanganese ehambelana ne-welding consumables egciniweyo yesinyithi

| Igama | Isikhundla | iimpawu zoomatshini | ||||

| YP | TS | EL | -196℃impembelelo | iimvavanyo zeradiographic | ||

| Iinjongo zoyilo | ≥400 | ≥660 | ≥25 | ≥41 | I | |

| IGER-HMA Φ3.2mm | I-electrode yokwenziwa ngesandla | 488 | 686 | 46.0 | 73.3 | I |

| I-GCR-HMA-S Φ3.2mm | I-Metal cored wire | 486 | 700 | 44.5 | 62.0 | I |

I-Ps.Metal powder core submerged arc welding wire yentsimbi ephezulu yemanganese ithatha i-flux ehambelanayo ne-GXR-200 yentsimbi ephezulu yemanganese.

I-Weldability kunye nomboniso wesampulu ye-manganese ephezulu yentsimbi ye-welding consumables kwiitanki zokugcina i-LNG

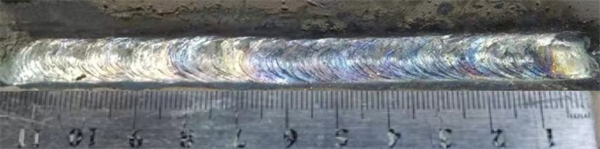

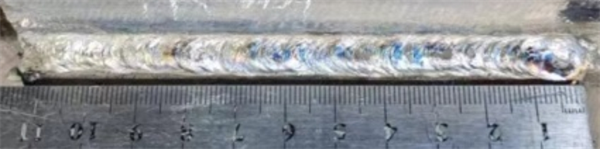

I-weldability ye-welding consumables kwintsimbi ephezulu ye-manganese iboniswa ngolu hlobo lulandelayo

I-Electrode (GER-HMA) i-flat fillet welding emva kokususwa kwe-slag

I-Electrode (GER-HMA) i-angle yokunyuka kwe-angle welding emva kokususwa kwe-slag

Intonga ye-Welding (GER-HMA) ngaphambi nangemva kokususwa kwe-fillet welding slag

Metal powder core submerged arc (GCR-HMA-S) weld display

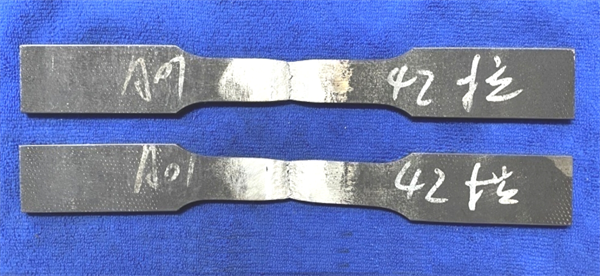

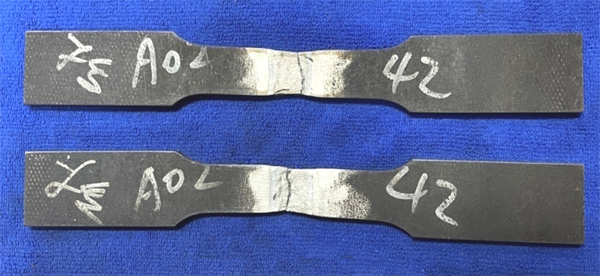

Iisampulu zentsimbi ephezulu ye-manganese ye-welding welding joints ziboniswa ngolu hlobo lulandelayo

I-flat welding (1G) umboniso wesampulu eqinile

I-welding ethe nkqo (3G) isiboniso sesampulu esiqinileyo

I-flat welding (1G) isampula yokugoba umboniso

I-flat welding (1G) isampula yokugoba umboniso

I-PS. High manganese intsimbi idityaniswe ngeentonga ze-welding 1G kunye ne-3G, akukho zintanda ebusweni bokugoba kunye neesampuli zokugoba ngasemva, kunye nokumelana nokuqhekeka kulungile.

Ixesha lokuposa: Nov-22-2022