Iwebhu: www.welding-honest.com +8613252736578

I-aluminiyam ecocekileyo yintsimbi ethambileyo kwaye esebenza kakuhle. Kwizakhiwo ezininzi, amandla ayo aphantsi. Ukwandisa ubuninzi be-aluminium, izinto ezidibeneyo kufuneka zongezwe. Ubhedu, i-silicon, i-manganese, i-magnesium, kunye ne-zinc zisetyenziswa njengeyona nto iphambili yokudlala i-soluble-soluble reinforcement effect. I-aluminiyam kunye ne-alloy ye-aluminium isetyenziswe ngokubanzi kumashishini amaninzi.

I-welding ye-aluminiyam kunye ne-aluminium alloy inzima kakhulu kunentsimbi ye-carbon ephantsi. Iimpawu zayo ze-welding zihluke kwi-low-carbon steel. Ukusebenza okuthe ngqo kolu hlobo lulandelayo:

1. I-Soferality ye-welded edibanisa ukusebenza komatshini, ukunciphisa ukuxhathisa kwe-corrosion.

2. Umsebenzi weekhemikhali unamandla kakhulu, kwaye umphezulu wenziwa lula.

3. I-conductivity enamandla ye-thermal, kwaye kulula ukubangela i-insoluble phenomenon ngexesha le-welding.

4. Iziphene ezilandelelanayo ezifana ne-pores, ii-cracks, i-bite edges, i-slag kunye ne-weld forming.

5. I-coefficient yokwandisa umgca omkhulu (malunga namaxesha ama-2 e-low-carbon steel), ehambelana ne-warp kunye ne-deformation ngexesha le-welding.

6. I-thermal conductivity inkulu (malunga namaxesha ama-5 e-low-carbon steel). Ngesantya esifanayo se-welding, igalelo le-thermal liphindwe kabini ukuya kuma-4 amakhulu kunentsimbi ye-welding.

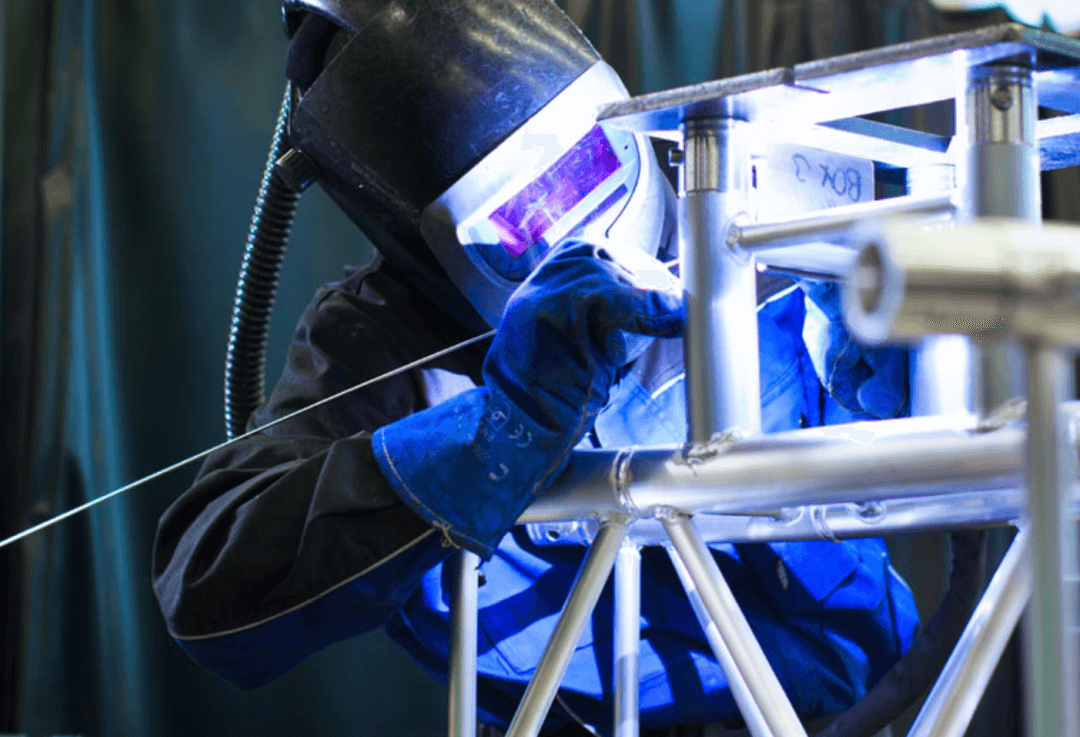

I-alloy ye-aluminium idityaniswe nge-TIG okanye i-GMAW.

I-1

Ukuba ufuna ukufumana olona mgangatho uphezulu welding, iTig welding ihlala lolona khetho lokuqala. Eyona ndlela ifanelekileyo yenkqubo kukutshintshisa i-TIG welding kunye ne-AC pulse TIG welding. Kukho iingenelo ezininzi:

1. Xa i-welding, iimpawu ze-atomization ze-cathode zingasuswa ngokwazo.

2. Ifom yokudibanisa ayiphelelanga, umphezulu ulungile kwaye ulungele ukubumba.

3. Ummandla we-welding we-airflow ukupholisa amajoyina ukupholisa kunye nokuphucula umbutho kunye nokusebenza.

Ke ngoko, le nkqubo ifanelekile kakhulu kwishishini elikumgangatho ophezulu kwaye libaluleke kakhulu kwi-aerospace. Kakade ke, iintsilelo zayo nazo zicace gca. Ukusebenza kwe-welding kuphantsi, kwaye ayifanelekanga ukuveliswa kwezinto ezinkulu eziphezulu.

I-1

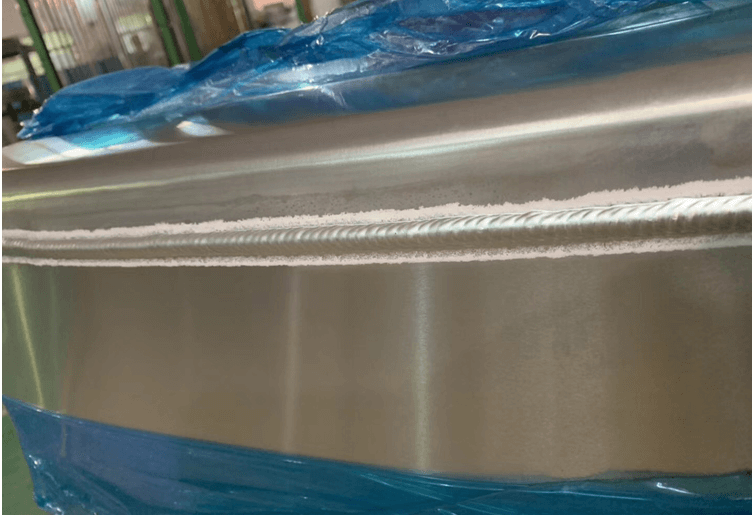

I-Gmaw welding ingene kancinci kancinci ebomini bethu. Uqhagamshelo lwe-DC reverse ludla ngokusetyenziswa ngexesha lokuwelda, kunye ne-pulse welding nayo ingasetyenziswa. Xa kuthelekiswa ne-TIG welding, ukuwelda kwe-GMAW kunezi nzuzo zilandelayo:

1. Phantse akukho ukutsha kwe-oxidative ngexesha lenkqubo ye-welding, kwaye inkqubo ilula.

2. Imveliso ephezulu yabasebenzi.

3. Musa ukuthatha izibonda ze-tungsten, ixabiso eliphantsi.

Xa welding kwi-GMAW, nikela ingqalelo kula manqaku alandelayo:

1. Kufuneka usebenzise i-hose ye-silk esekelwe kwiplastiki, kwaye i-hose yensimbi ayinakusetyenziswa.

2. I-aluminium welding wire ithambile kwaye ukuhanjiswa kwecingo kubi. Kufuneka ukhethe ivili lonikezelo locingo lwe-U-shaped groove.

3. Sebenzisa umlomo ohambisa idiameter efanelekileyo.

4. Musa ukwabelana ngamacandelo nge-welding yensimbi ukuze ugweme ukungcola.

I-GMA-A5356 isebenzisa umphumo kwindawo yomthengi

Le datha yabelana nabasebenzisi abaqhubayo okanye abaza kuxutywa, okusivumela ukuba senze inkqubela kwindlela ye-aluminium alloy welding.

Iimveliso zobonelelo eziqhelekileyo zenkampani yethu zezi zilandelayo:

TIG MIG

I-GTA-A4043 GMA-A4043

I-GTA-A5183 GMA-A5183

I-GTA-A5356 GMA-A5356

Ixesha lokuposa: Nov-14-2022