Ngexesha lenkqubo yokuqina, iintanda zihlala zibangela iingxaki ezifana nokusebenza kwakhona kunye nokubuya kwabathengi. Umphezulu oqinileyo wahlukile kwi-welding yesakhiwo ngokubanzi, kwaye isigwebo kunye nomkhombandlela wokuqwalaselwa kweentanda nazo zahluke kakhulu. Eli nqaku lihlalutya kwaye lixoxe ngenkangeleko eqhelekileyo yeentanda kwinkqubo yobuso obuqinileyo obungagungqiyo.

1. Ukuzimisela kweentanda

Okwangoku, ngaphakathi nakwamanye amazwe, akukho mgangatho jikelele wokuqhekeka okubangelwa kukunxiba komphezulu oqinileyo. Esona sizathu siphambili kukuba zininzi kakhulu iintlobo zeemeko zokusebenza kwiimveliso zokunxiba komphezulu onzima, kwaye kunzima ukuchaza iindlela ezahlukeneyo ezisebenzayo zokugweba ngokuqhekeka phantsi kweemeko. Nangona kunjalo, ngokwamava ekusetyenzisweni kwezixhobo zokuwelda ezijongene nobuso obuqinileyo kwiinkalo ezahlukeneyo, iidigri ezininzi ze-crack zinokulungiswa ngokufanelekileyo, kunye nemigangatho yokwamkelwa kumashishini ahlukeneyo:

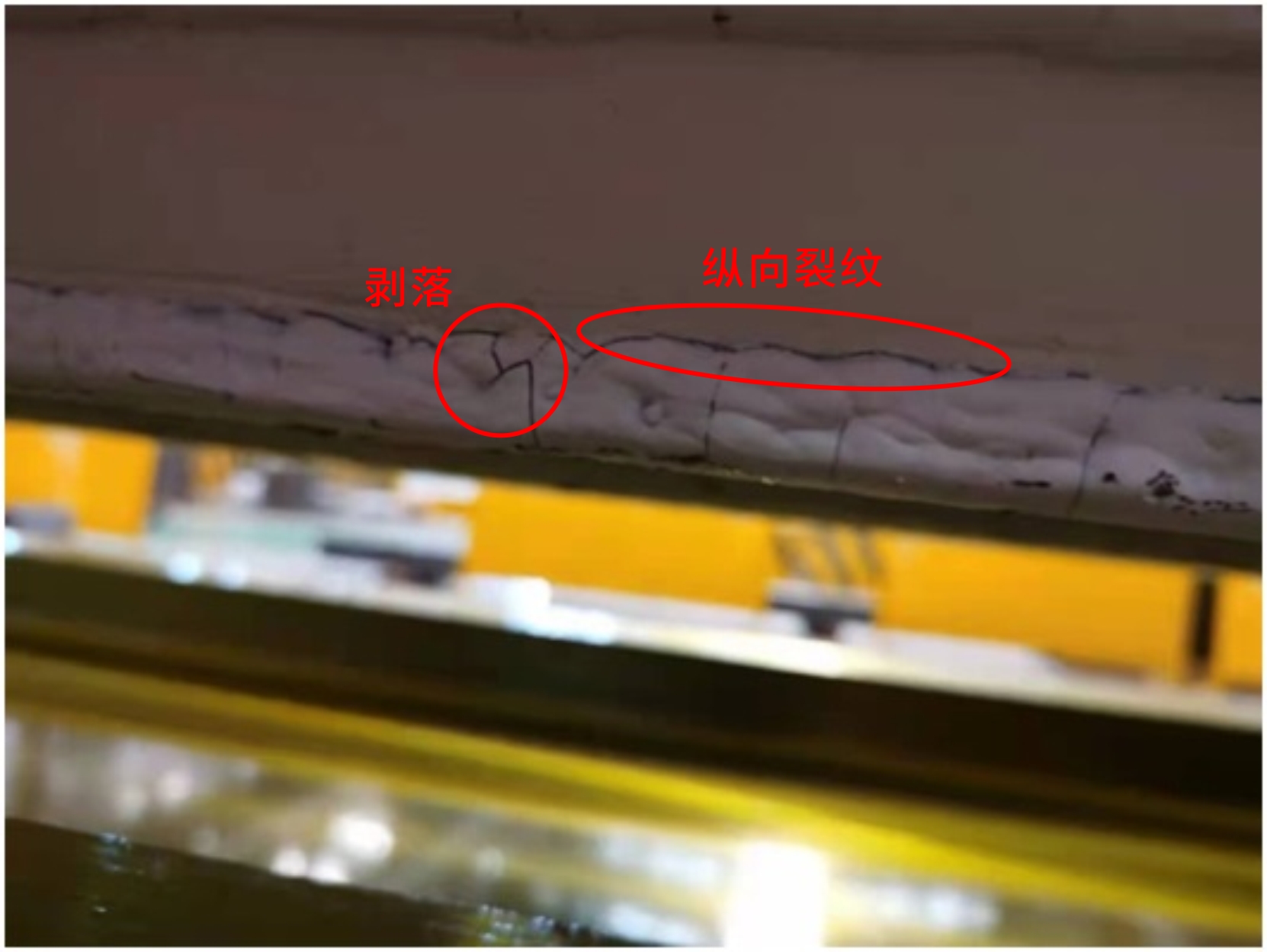

1. Isalathiso sokuqhekeka sihambelana ne-weld bead (i-longitudinal crack), i-crack eguquguqukayo eqhubekayo, i-crack eya kwisiseko sesinyithi, i-spalling.

Logama nje elinye lala manqanaba okuqhekeka akhankanywe ngasentla lihlangatyeziwe, kukho umngcipheko wokuba wonke umaleko ongaphezulu uya kuwa. Ngokusisiseko, kungakhathaliseki ukuba yintoni isicelo semveliso, ayimkelekanga kwaye inokuphinda ihlaziywe kwaye iphinde ithengiswe.

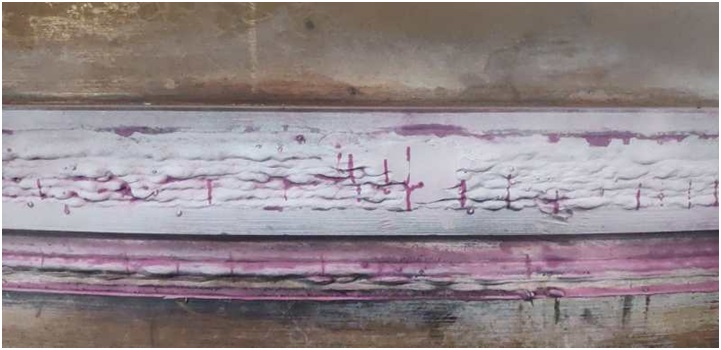

2. Kukho iintanda ezinqamlezileyo kuphela kunye nokungaqhubeki

Kwizixhobo zokusebenza ezidityaniswe nezixhobo eziqinileyo ezifana nentsimbi ekrwada, ilitye lentlabathi, kunye nemigodi yamalahle, ukuqina kuyafuneka ukuba kuphakame (HRC 60 okanye ngaphezulu), kunye nezixhobo zokuwelda ezikwi-chromium ephezulu ziqhele ukusetyenziselwa ukuwelda. I-chromium carbide crystals eyenziwe kwi-weld bead iya kuveliswa ngenxa yokukhululwa koxinzelelo. Iintanda zamkelekile ukuba ulwalathiso lokuqhekeka luxhomekeke kuphela kwi-weld bead (transverse) kwaye ayiqhubeki. Nangona kunjalo, inani lokuqhekeka liya kusetyenziswa njengesalathiso sokuthelekisa iingenelo kunye nokungonakali kwezinto ezisetyenziswayo ze-welding okanye iinkqubo zokujonga phezulu.

3. Akukho ntsimbi ye-crack weld

Kuba workpieces ezifana flanges, iivalvu, kunye nemibhobho, apho izinto eziphambili zoqhagamshelwano iigesi kunye nolwelo, iimfuno iintanda kwi bead weld zilumke ngakumbi, kwaye ngokubanzi efunekayo ukuba inkangeleko weld bead kufuneka kungabikho iintanda.

Ukuqhekeka okuncinci kumphezulu wezinto zokusebenza ezinje ngeeflange kunye neevalvu kufuneka zilungiswe okanye zisetyenzwe kwakhona.

Sebenzisa i-GFH-D507Mo yenkampani yethu i-valve ekhethekileyo yezinto ezisetyenziselwa ukuwelda kwindawo engaphezulu, akukho zintanda kumphezulu.

2. Ezona zinto zibangela ukuba kubekho iintanda eziqinileyo zomphezulu oqinileyo

Zininzi izinto ezibangela iintanda. Kwiwelding eqinileyo yomgangatho oqinileyo we-surfacing, inokwahlulwa ikakhulu ibe ziintanda ezishushu ezinokufumaneka emva kokudlula okokuqala okanye okwesibini, kunye neentanda ezibandayo ezivela emva kokupasa okwesibini okanye nasemva kwayo yonke i-welding.

Ukuqhekeka okushushu:

Ngethuba lenkqubo ye-welding, isinyithi kwi-weld seam kunye nendawo echaphazelekayo yokushisa ipholisa kwindawo ephezulu yokushisa kufuphi nomgca we-solidus ukuvelisa iintanda.

Ukuqhekeka okubandayo:

Ukuqhekeka okwenziwe kumaqondo obushushu angaphantsi kwe-solidus (malunga nobushushu be-martensitic yokuguqulwa kwentsimbi) kwenzeka kakhulu kwiintsimbi ze-carbon medium-carbon kunye ne-high-high-high-high-alloy alloy steels kunye ne-medium-alloy steels.

Njengoko igama libonisa, iimveliso zomphezulu oqinileyo zaziwa ngokuqina kwazo okuphezulu. Nangona kunjalo, ukufuna ubunzima kubuchwephesha kukhokelela ekunciphiseni kweplastiki, oko kukuthi, ukunyuka kwe-brittleness. Ngokubanzi, ukuvela ngaphezulu kwe-HRC60 akuhoyi kakhulu kwiintanda ze-thermal ezenziwe ngexesha lenkqubo ye-welding. Nangona kunjalo, ukuwelda okuqinileyo kunye nobunzima phakathi kwe-HRC40-60, ukuba kukho imfuneko yokuqhekeka, Ukuqhekeka kwe-intergranular kwinkqubo ye-welding okanye i-liquefaction kunye neentanda ezininzi ezibangelwa yi-weld bead ephezulu ukuya kwindawo echatshazelwe bubushushu kwi-weld ephantsi. bead zinzima kakhulu.

Nokuba ingxaki yeentanda ezishushu zilawulwa kakuhle, izoyikiso zokuqhekeka okubandayo ziseza kujongana nazo emva kokuwela i-welding, ngakumbi izinto eziqhekeka kakhulu ezifana ne-hard surface weld bead, ebuthathaka kakhulu kwiintanda ezibandayo. Ukuqhekeka okuqatha kubangelwa ikakhulu ziintanda ezibandayo

3. Izinto ezibalulekileyo ezichaphazela ukuqhekeka okungagungqiyo kwiindawo eziqinileyo kunye nezicwangciso zokuphepha ukuqhekeka

Izinto ezibalulekileyo ezinokuphononongwa xa ukuqhekeka kwenzeka kwinkqubo yokugqoka umphezulu onzima ngolu hlobo lulandelayo, kwaye izicwangciso ezihambelanayo zicetywayo kwinto nganye yokunciphisa umngcipheko wokuqhekeka:

1. Izinto ezisisiseko

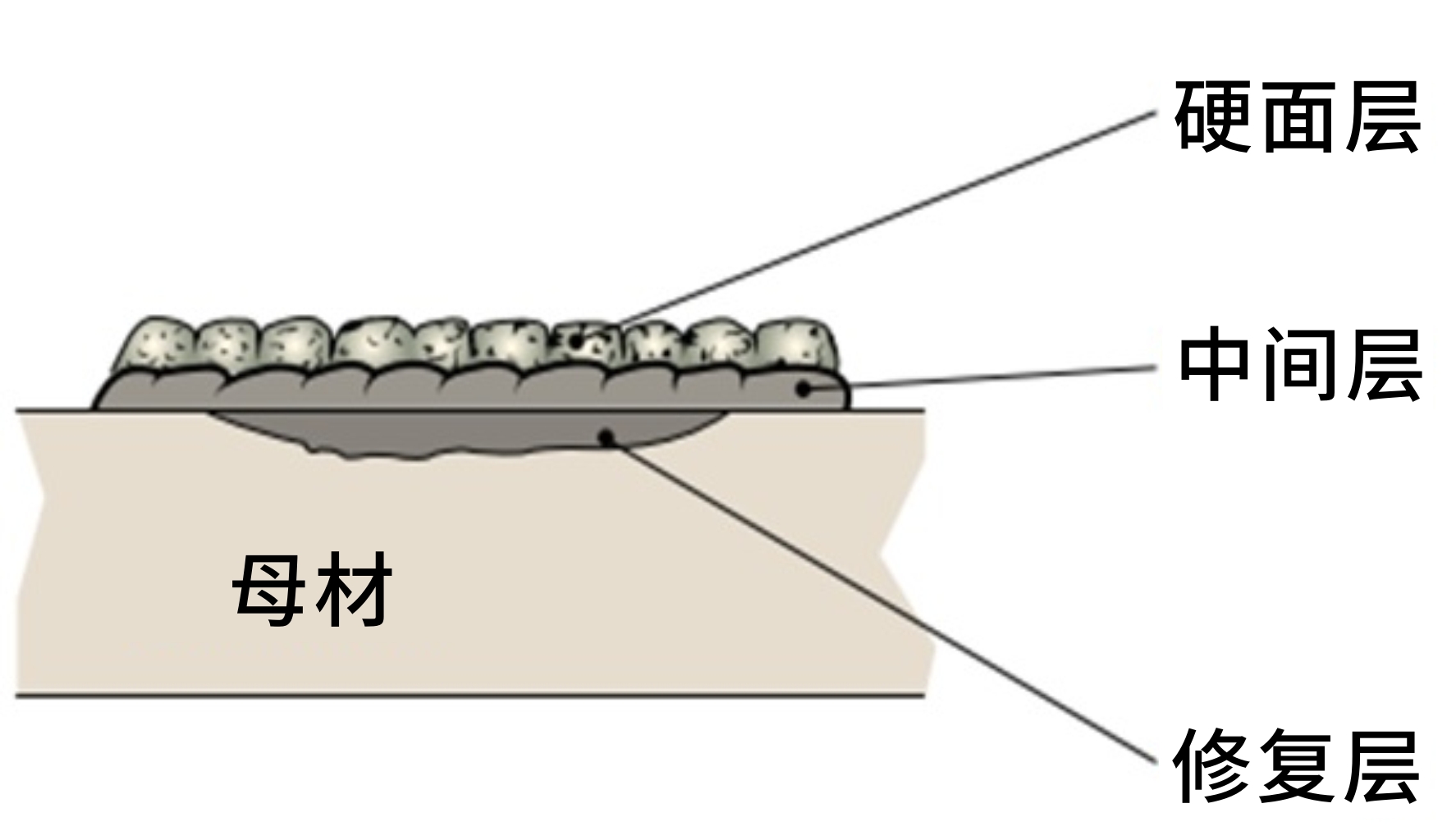

Impembelelo yesiseko sentsimbi kumphezulu oqinileyo okwaziyo ukumelana nokunxiba ibaluleke kakhulu, ngakumbi kwizinto zokusebenza ezinomaleko ongaphantsi kwe-2 wokuwelda. Ukubunjwa kwesiseko sentsimbi kuchaphazela ngokuthe ngqo iipropati ze-weld bead. Ukukhethwa kwezinto eziphathekayo yinkcukacha ekufuneka ithathelwe ingqalelo ngaphambi kokuqala umsebenzi. Umzekelo, ukuba i-valve workpiece enobulukhuni obujoliswe kuyo malunga ne-HRC30 ijongene nesiseko sentsimbi, kuyacetyiswa ukuba kusetyenziswe izinto zokuwelda ezinobunzima obuphantsi kancinci, okanye ukongeza umaleko wentsimbi ephakathi, ukuze thintela umxholo wekhabhoni kwizinto ezisisiseko ekunyuseni umngcipheko wokuqhekeka kweentsimbi ze-weld.

Yongeza umaleko ophakathi kwizinto ezisisiseko zokunciphisa umngcipheko wokuqhekeka

2. I-Welding Consumables

Kwinkqubo engafuni ukuqhekeka, i-high-carbon kunye ne-high-chromium welding consumables ayifanelekanga. Kucetyiswa ukuba kusetyenziswe izixhobo ze-welding ze-martensitic, ezifana ne-GFH-58 yethu. Iyakwazi ukuwelda umphezulu wamaso ongenantandabuzo xa ubulukhuni buphezulu njenge-HRC58~60, ingakumbi ilungele imiphezulu yokusebenzela engacwangciswanga erhawuzelela kakhulu ngomhlaba namatye.

3. Igalelo lobushushu

Ulwakhiwo kwisiza luthanda ukusebenzisa umsinga ophakamileyo kunye nombane ngenxa yogxininiso ekusebenzeni kakuhle, kodwa ukunciphisa ngokuphakathi amandla akhoyo kunye nombane kunokunciphisa ngempumelelo ukwenzeka kokuqhekeka kwe-thermal.

4. Ukulawula ubushushu

I-Multi-layer kunye ne-multi-pass hardfacing welding inokuthathwa njengenkqubo yokufudumeza okuqhubekayo, ukupholisa kunye nokufudumeza kwakhona kwipasi nganye, ngoko ke ulawulo lobushushu lubaluleke kakhulu, ukusuka ekufudumezweni ngaphambi kokuba i-welding idlulise ubushushu ngexesha lokulawula ukuvela, kunye nenkqubo yokupholisa emva kokupholisa. welding, kufuna ingqalelo enkulu.

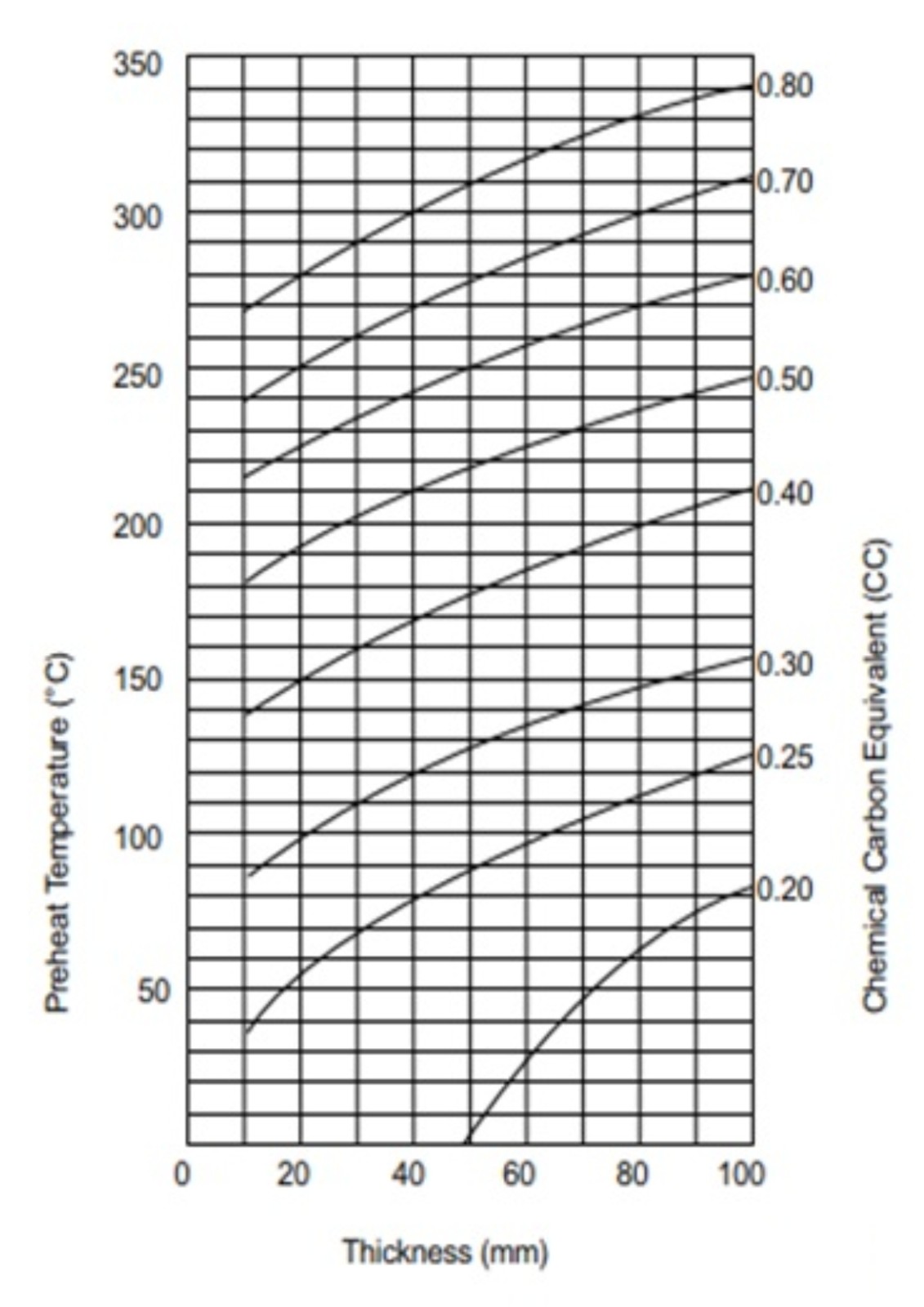

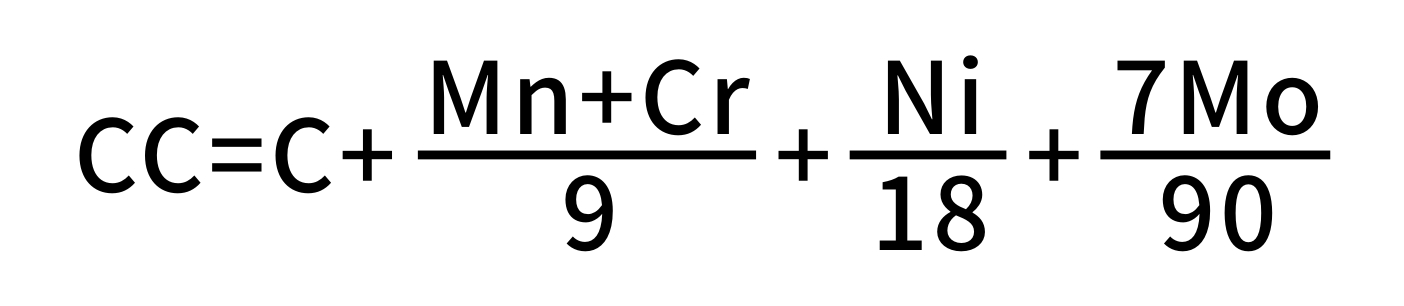

Ukushisa kwangaphambili kunye nokulandelela ukushisa kwe-welding ye-surfacing kuhambelana ngokusondeleyo nomxholo wekhabhoni we-substrate. I-substrate apha ibandakanya izinto ezisisiseko okanye umaleko ophakathi, kunye nezantsi kwendawo enzima. Ngokuqhelekileyo, ngenxa yesiqulatho sekhabhoni yentsimbi enzima efakwe kwintsimbi Ukuba umxholo uphezulu, kucetyiswa ukuba kugcinwe ubushushu bendlela ngaphezu kwama-200 degrees. Nangona kunjalo, ekusebenzeni okwenyani, ngenxa yobude obude be-weld bead, indawo engaphambili ye-weld bead sele ipholile ekupheleni kwesinye, kwaye ipasi yesibini iya kuvelisa ngokulula iintanda kwindawo echaphazeleke bubushushu ye-substrate. . Ngoko ke, ngokungabikho kwezixhobo ezifanelekileyo zokugcina ubushushu bomjelo okanye ukufudumala ngaphambi kwe-welding, kucetyiswa ukuba kusebenze kumacandelo amaninzi, i-welds emfutshane, kunye ne-welding eqhubekayo ye-surfacing kwicandelo elifanayo ukuze kugcinwe ukushisa kwesiteshi.

Ubudlelwane phakathi komxholo wekhabhoni kunye nokushisa kwangaphambili

Ukupholisa okucothayo emva kokujonga phezulu kwakhona kulinyathelo elibaluleke kakhulu kodwa elihlala lingahoywa, ngakumbi kwizinto ezinkulu zokusebenza. Ngamanye amaxesha akulula ukuba nezixhobo ezifanelekileyo ukunika iimeko zokupholisa kancinci. Ukuba ngokwenene akukho ndlela yokusombulula le meko, sinokuyincoma kuphela ukuba siyisebenzise kwakhona Indlela yokusebenza ngokwahlukeneyo, okanye ukuphepha ukuthungela i-welding xa ubushushu buphantsi, ukunciphisa umngcipheko weentanda ezibandayo.

Isine. Ukuqukumbela

Kusekho iiyantlukwano ezininzi zomenzi ngamnye kwiimfuno zokuqiniswa kokuqina kwiintanda kwizicelo ezibonakalayo. Eli nqaku lenza kuphela ingxoxo erhabaxa esekelwe kumava anqongopheleyo. Uluhlu lwenkampani yethu oluqinileyo olukwazi ukumelana nokunxitywa kwezinto ezityiwayo ze-welding zineemveliso ezihambelanayo ukuze abathengi bazikhethele ubunzima obahlukeneyo kunye nokusetyenziswa. Wamkelekile ukuba uthethe neshishini kwisithili ngasinye.

Ukusetyenziswa komzi mveliso webhodi odityanisiweyo onganxibiyo

| Into | Khusela irhasi | ubukhulu | Engundoqo | HRC | Ukusebenzisa |

| GFH-61-0 | Ukuzikhusela | 1.6 2.8 3.2 | C:5.0 Si:0.6 Mnu:1.2 Cr:28.0 | 61 | Ilungele amavili okugaya, abaxube besamente, iibulldozers, njl. |

| GFH-65-0 | Ukuzikhusela | 1.6 2.8 3.2 | C:5.0 IsiKr:22,5 Mo:3.2 V:1.1 W:1.3 Nb:3.5 | 65 | Ilungele ubushushu obuphezulu bokususwa kwee-fan blades, izixhobo zokutyisa eziko lokuqhushumba, njl. |

| GFH-70-O | Ukuzikhusela | 1.6 2.8 3.2 | C:5.0 Cr:30.0 B:0.3 | 68 | Isebenza kwi-roller yamalahle, i-ghost red, i-gear yokufumana, i-blast cover yamalahle, i-grinder, njl. |

Isicelo kwishishini lesamente

| Into | Khusela irhasi | ubukhulu | Engundoqo | HRC | Ukusebenzisa |

| GFH-61-0 | Ukuzikhusela | 1.6 2.8 3.2 | C:5.0 Si:0.6 Mnu:1.2 Cr:28.0 | 61 | Kufanelekile ukugaya ii-roller zamatye, abaxube be-samente, njl |

| GFH-65-0 | Ukuzikhusela | 1.6 2.8 3.2 | C:5.0 IsiKr:22,5 Mo:3.2 V:1.1 W:1.3 Nb:3.5 | 65 | Ilungele ubushushu obuphezulu bokususwa kwee-fan blades, izixhobo zokutyisa eziko lokuqhushumba, njl. |

| GFH-70-O | Ukuzikhusela | 1.6 2.8 3.2 | C:5.0 Cr:30.0 B:0.3 | 68 | Kufanelekile ukugaya i-roller yamatye, amazinyo omoya, ukufumana amazinyo, i-grinders, njl. |

| GFH-31-S | GXH-81 | 2.8 3.2 | C:0.12 Si:0.87 Mnu:2.6 Mo:0.53 | 36 | Isebenza kwiindawo zokunxiba zentsimbi ukuya kwintsimbi ezifana namavili esithsaba kunye neeasi |

| GFH-17-S | GXH-81 | 2.8 3.2 | C:0.09 Si:0.42 Mnu:2.1 IsiKr:2.8 Mo:0.43 | 38 | Isebenza kwiindawo zokunxiba zentsimbi ukuya kwintsimbi ezifana namavili esithsaba kunye neeasi |

Isicelo seSityalo seNsimbi

| Into | Khusela irhasi | ubukhulu | Engundoqo | HRC | Ukusebenzisa |

| GFH-61-0 | Ukuzikhusela | 1.6 2.8 3.2 | C:5.0 Si:0.6 Mnu:1.2 Cr:28.0 | 61 | Ilungele ukutshiza imivalo yesithando somlilo, amazinyo esiporho, iipleyiti ezikwaziyo ukunxiba, njl. |

| GFH-65-0 | Ukuzikhusela | 1.6 2.8 3.2 | C:5.0 IsiKr:22,5 Mo:3.2 V:1.1 W:1.368 Nb:3.5 | 65 | |

| GFH-70-0 | Ukuzikhusela | 1.6 2.8 3.2 | C:5.0 Cr:30.0 B:0.3 | 68 | |

| GFH-420-S | GXH-81 | 2.8 3.2 | C:0.24 Si:0.65 Mnu:1.1 IsiKr:13.2 | 52 | Ifanelekile kwi-casting rolls, i-rolls rolls, i-steering rolls, njl. kwizityalo eziqhubekayo zokuphosa kunye nezityalo ezishushu ezijikelezayo. |

| GFH-423-S | GXH-82 | 2.8 3.2 | C:0.12 Si:0.42 Mnu:1.1 IsiKr:13.4 Mo:1.1 V:0.16 Nb:0.15 | 45 | |

| GFH-12-S | GXH-81 | 2.8 3.2 | C:0.25 ISi:0.45 Mnu:2.0 IsiKr:5.8 Mo:0.8 V:0.3 W:0.6 | 51 | Iipropathi zokunxiba ezichasene nokuncamathelisa, ezifanelekileyo kwimiqulu yokulawula ipleyiti yomzi-mveliso, i-pinch rolls kunye neendawo zokunxiba phakathi kweentsimbi. |

| GFH-52-S | GXH-81 | 2.8 3.2 | C:0.36 ISi:0.64 Mnu:2.0 Ni:2.9 IsiKr:6.2 Mo:1.35 V:0.49 | 52 |

Isicelo soMgodi

| Into | Khusela irhasi | ubukhulu | Engundoqo | HRC | Ukusebenzisa |

| GFH-61-0 | Ukuzikhusela | 1.6 2.8 3.2 | C:5.0 Si:0.6 Mnu:1.2 Cr:28.0 | 61 | Isebenza kwi-excavators, i-roadheaders, i-picks, njl. |

| GFH-58 | CO2 | 1.6 2.4 | C:0.5 Si:0.5 Mnu:0.95 Ngo:0.03 IsiKr:5.8 Mo:0.6 | 58 | Ifanelekile kwi-welding ye-surfacing kwicala lokuhambisa ilitye |

| GFH-45 | CO2 | 1.6 2.4 | C:2.2 Si:1.7 Mnu:0.9 Cr:11.0 Mo:0.46 | 46 | Ifanelekile ukunxiba iinxalenye phakathi kweentsimbi |

Ukusetyenziswa kwevalvu

| Into | Khusela irhasi | ubukhulu | Engundoqo | HRC | Ukusebenzisa |

| GFH-D507 | CO2 | 1.6 2.4 | C:0.12 S:0.45 Mnu:0.4 Ni:0.1 IKhr:13 Mo:0.01 | 40 | Ifanele ukuwelda phezu komphezulu wevalve yokutywina |

| GFH-D507Mo | CO2 | 1.6 2.4 | C:0.12 S:0.45 Mnu:0.4 Ni:0.1 IKhr:13 Mo:0.01 | 58 | Ifanele i-welding ye-surfacing yeevalvu ezinokudleka okuphezulu |

| GFH-D547Mo | Iinduku zezandla | 2.6 3.2 4.0 5.0 | C:0.05 Mnu:1.4 Si:5.2 P:0.027 S:0.007 Ni:8.1 IsiKr:16.1 Mo:3.8 Nb:0.61 | 46 | Ifanele ubushushu obuphezulu, ivalve yoxinzelelo oluphezulu ijonge i-welding |

More information send to E-mail: export@welding-honest.com

Ixesha lokuposa: Dec-26-2022