I. Isishwankathelo

Ngophuhliso olukhawulezayo lwemveliso yoomatshini, izakhiwo ezidityanisiweyo ezifana nobunjineli bale mihla kunye neenqanawa zoxinzelelo ziyaphuhla zisiya kwiindlela ezinkulu nezikhaphukhaphu. Iimfuno zemigangatho yamandla entsimbi ziya phezulu nangaphezulu, azifuni nje iipropathi ezilungileyo ezibanzi zoomatshini, kodwa kunye nokuqhubekeka okuhle, ukuwelda kunye nokumelana nokuqhekeka.

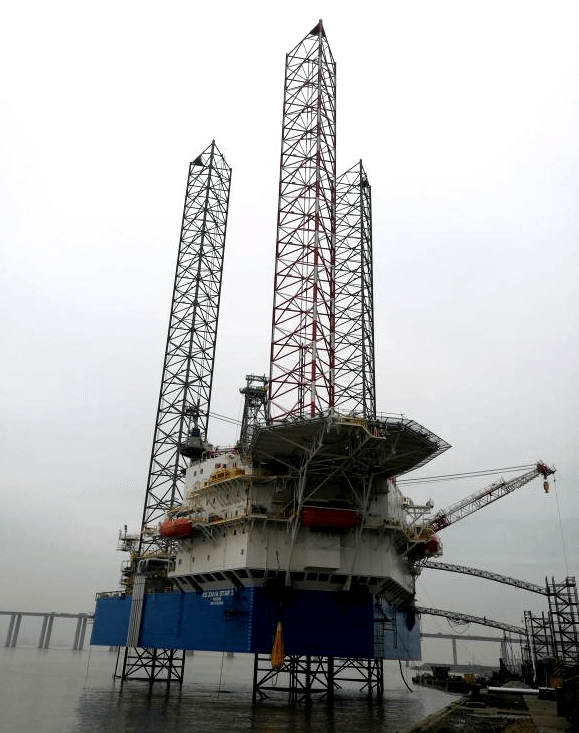

Intsimbi ye-Q690 yeyentsimbi yolwakhiwo oluqinileyo oluphezulu, apho i-Q imele isivuno, kwaye i-690 ithetha inqanaba lamandla esivuno yi-690MPa. I-690MPa yenqanaba lentsimbi inesivuno esiphezulu kunye namandla okuqina, kwaye isetyenziswa ngokubanzi kumatshini wemigodi yamalahle, oomatshini bokwakha, ubunjineli baselwandle, amaqonga aselwandle, iinqanawa zoxinzelelo, njl., ifuna intsimbi ibe namandla aphezulu esivuno kunye nomda wokudinwa, ukuqina kwempembelelo entle, kubanda. ukwakheka kunye nokuwelda okugqwesileyo.

I-2.Inkcazo emfutshane ye-Q690 plate yensimbi

| Amazwe ngamazwe Q690 ibakala lentsimbi | Q690A | Q690B | Q690C | Q690D | Q690E | Q690F |

| Usiba | Ishushu esongwayo | Ukucima + ukucaphuka (imeko ecinyiweyo kunye nenomsindo) | ||||

| Umxholo wokungcola | I-P/S ephezulu | P/S ephantsi | Ubuncinci be-P/S | |||

| IiMfuno zokothuka | NO | Ukutshatyalaliswa kobushushu obuqhelekileyo | 0℃ | -20℃ | -40℃ | -60℃ |

Nangona kunjalo, okwangoku, i-690MPa ipleyiti yentsimbi yeenqanawa zoxinzelelo lwasekhaya isekelwe ikakhulu kumgangatho waseYurophu EN10028-6, kwaye iipropati ezifanelekileyo zidweliswe ngokufutshane kule theyibhile ilandelayo:

| Imveliso yentsimbi ye-690MPA yezixhobo zoxinzelelo ezisemgangathweni zaseYurophu | P690Q | P690QH | I-P69QL1 | P69QL2 |

| Usiba | ingqolowa ecikiziweyo kunye nentsimbi epholileyo | |||

| iimfuno zamandla | Yield≥690MPa(plete thickness≤50mm) Tensile770-940MPa | |||

| Umxholo wokungcola | P≤0.025%,S≤0.015% | P≤0.02%,S≤0.010% | ||

| IiMfuno zokothuka | 20℃≥60J | 20℃≥60J | 0℃≥60J | -20℃≥40J |

| 0℃≥40J | 0℃≥40J | -20℃≥40J | -40℃≥27J | |

| -20℃≥27J | -20℃≥27J | -40℃≥27J | -60℃≥27J | |

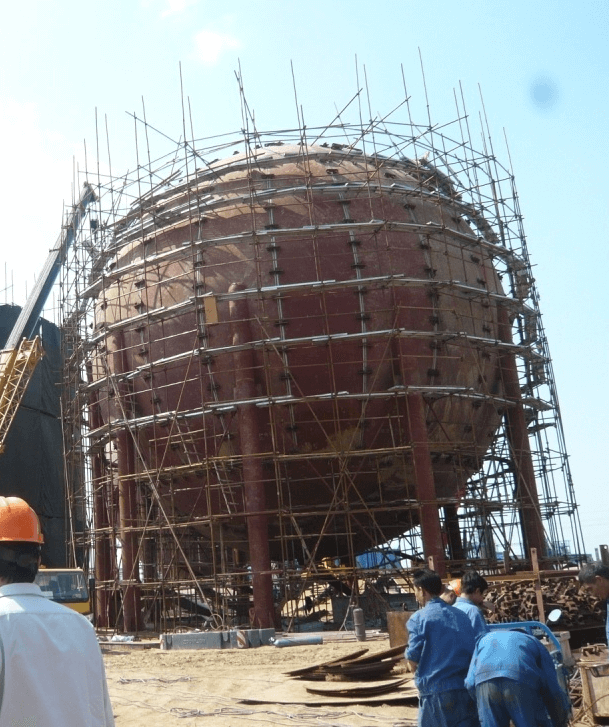

| Iindawo zesicelo eziphambili | Izakhiwo ezithwele uxinzelelo okanye iinqanawa zoxinzelelo ezineemfuno zokuqina kwempembelelo ephantsi | Itanki engqukuva eneemfuno eziphezulu zobugcisa | Itanki yolwelo lwerhasi enyibilikileyo yaselwandle | |

Njengepleyiti yentsimbi yokugcina iitanki kunye nomthamo woxinzelelo, kufuneka ibe namandla amahle kunye nokuqina, ukusebenza okugoba okubandayo kunye novakalelo oluphantsi lokuqhekeka. Nangona intsimbi ecinyiweyo kunye nobushushu be-Q690 inomgangatho ophantsi wekhabhoni olinganayo kunye neempawu ezigqibeleleyo ezibanzi, isenotyekelo oluthile lokuqina xa kuthelekiswa nezinye iintsimbi zoxinzelelo lwe-50/60kg, kunye nonyango lobushushu be-post-weld luyafuneka. Nangona kunjalo, inani elikhulu lophononongo lovavanyo lubonise ukuba kwi-Q690 ye-welding yensimbi esetyenziswayo, ukuqina kwempembelelo yobushushu obuphantsi kuya kuba mbi kakhulu emva kokunyangwa kobushushu boxinzelelo, kunye nokunyuka kobushushu bonyango kunye nokuncipha kweqondo lobushushu, ukuwohloka. ukuwelda ukuqina consumable kuya kubonakala ngakumbi. Ngoko ke, kubaluleke kakhulu ukuphuhlisa amandla aphezulu, ukuqina kwempembelelo ephezulu, kunye neentonga ze-welding eziphathwa ukushisa ze-Q690 zensimbi ukuze zifake ngempumelelo i-Q690 yentsimbi kwizixhobo ezithwala uxinzelelo, ukunciphisa izixhobo zetsimbi, kunye nokunciphisa iindleko zokuvelisa.

I-3.Inkcazo emfutshane ye-Q690 yethu yentsimbi ye-welding

| Into | Umgangatho | Uhlobo lwesikhumba | I-Polarity | iimpawu eziphambili |

| IGEL-118M | AWS A5.5 E1108MISO 18275-BE7618-N4M2A | Umgubo wentsimbi ephantsi uhlobo lwe-hydrogen | DC+/AC | Amandla aphezulu, i-hydrogen ephantsi, ukusebenza kakuhle kwe-deposition, iipropathi ezizinzileyo zomatshini, ubushushu obuphezulu befuthe lokuqina kwi -50 ° C, kunye nokuqina okuhle kwi-40 ° C emva konyango lobushushu. |

| IGEL-758 | AWS A5.5 E11018-GISO 18275-BE7618-G A | Umgubo wentsimbi ephantsi uhlobo lwe-hydrogen | DC+/AC | I-Hydrogen ephantsi kakhulu, ukusebenza kakuhle kokubekwa, ukuqina okuphezulu (-60℃≥70J), ukuqina kwempembelelo entle ku -40/ -50 ℃ emva konyango lobushushu. |

| IGEL-756 | AWS A5.5 E11016-GISO 18275-BE7616-G A | Uhlobo oluphantsi lwe-hydrogen potassium | AC/DC+ | I-Hydrogen ephantsi kakhulu, i-AC/DC+ injongo-mbini, ukuqina kwempembelelo ephezulu (-60℃≥70J), ukuqina kwempembelelo elungileyo kwi -50/ -60 ℃ emva konyango lobushushu. |

4.Q690 intsimbi welding intonga mechanical ukusebenza ukubonisa

| Into | As-welding iimpawu mechanical | ||||||

| Imbuyekezo yeMPA | Ukuqina kweMPA | Yandisa % | Ipropati yempembelelo J/℃ | Uvavanyo lweRadiographic | I-hydrogen edibeneyo Ml/100g | ||

| -50℃ | -60℃ | ||||||

| AWS A5.5 E11018M | 680- 760 | ≥760 | ≥20 | ≥27 | - | I | - |

| ISO 18275-B E7618-N4M2A | 680- 760 | ≥760 | ≥18 | ≥27 | - | I | - |

| IGEL-118M | 750 | 830 | 21.5 | 67 | 53 | I | 3.2 |

| AWS A5.5 E1101X-G | ≥670 | ≥760 | ≥15 | - | - | I | - |

| ISO 18275B E761X-GA | ≥670 | ≥760 | ≥13 | - | - | I | - |

| IGEL-758 | 751 | 817 | 19.0 | 90 | 77 | I | 3.4 |

| IGEL-756 | 764 | 822 | 19.0 | 95 | 85 | I | 3.6 |

Bonisa:

1. U-"X" ophawulwe ngefonti ebomvu kuMgangatho waseMelika kunye noMgangatho waseYurophu umele uhlobo lwesikhumba seziyobisi.

2. I-GEL-758 ihambelana ne-E11018-G kunye ne-ISO 18275-B E7618-G A kwi-AWS kunye nemigangatho ye-ISO ngokulandelanayo.

3. I-GEL-756 ihambelana ne-E11016-G kunye ne-ISO 18275-B E7616-G A kwi-AWS kunye nemigangatho ye-ISO ngokulandelanayo.

Iipropati ze-Mechanical ze-Q690 zentsimbi ye-welding kwimo yonyango lokushisa

| Into | Iipropati zoomatshini bombuso wokuphathwa kobushushu | ||||||

| Imbuyekezo yeMPA | Ukuqina kweMPA | Yandisa % | Ipropati yempembelelo J/℃ | Ukufudumeza ℃*h | |||

| -40℃ | -50℃ | -60℃ | |||||

| Injongo yeprojekthi | ≥670 | ≥760 | ≥15 | ≥60 | ≥52 | ≥47 | 570*2 |

| IGEL-118M | 751 | 827 | 22.0 | 85 | 57 | - | 570*2 |

| IGEL-758 | 741 | 839 | 20.0 | 82 | 66 | 43 | 570*2 |

| IGEL-756 | 743 | 811 | 21.5 | 91 | 84 | 75 | 570*2 |

Bonisa:

1. Imigangatho enxulumene ne-AWS kunye ne-ISO ayinayo imfuneko yokusebenza yonyango lobushushu kwiimveliso ezingentla. Olu nyango lobushushu lungasentla lushwankathelwa ngokusekelwe kwiimeko zobugcisa zabathengi abaninzi kwaye zenzelwe ireferensi kuphela.

2. I-GEL-118M inokuqina kwempembelelo egqwesileyo kwi--40 ° C emva kokunyangwa kobushushu, kwaye ukuchithwa kwempembelelo kwi -50 ° C kubonakala ngakumbi.

3. Emva kokunyangwa kobushushu, i-GEL-758 inefuthe elihle kakhulu kwi--40 ° C, ukuqina kwempembelelo elungileyo kwi--50 ° C, kunye nokuwohloka okucacileyo kwiqondo lokushisa eliphantsi -60 ° C.

4. Impembelelo ephantsi yobushushu bempembelelo ye-GEL-756 emva kokunyangwa kobushushu buncinci, kwaye i-low-temperature toughness kwi -60 ° C isalungile.

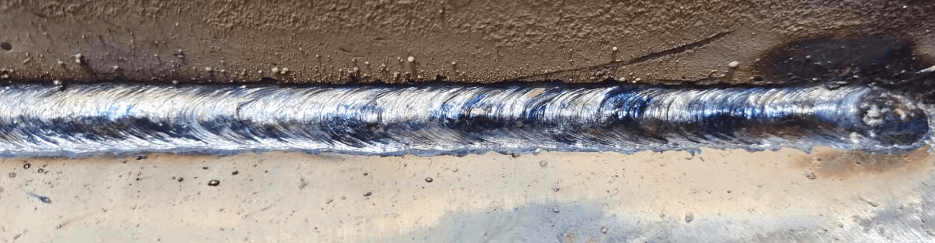

Umboniso we-Weldability we-Q690 welding yentsimbi

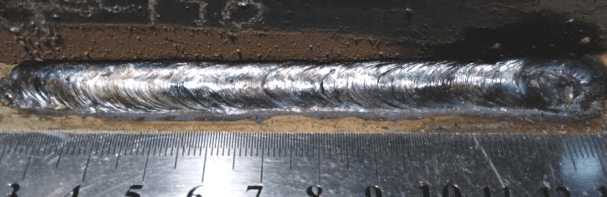

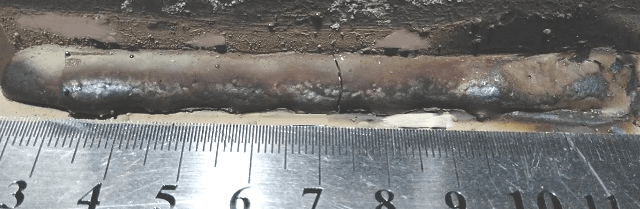

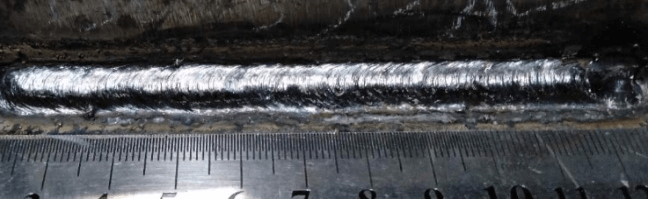

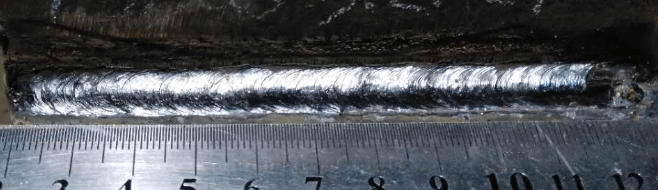

1.I-Flat fillet welding (φ4.0mm)

I-GEL-118M i-flat fillet welding ngaphambi nasemva kokususwa kwe-slag (DC+)

Ngaphambi nasemva kwe-GEL-758 i-flat fillet welding slag ukususwa (DC+)

I-GEL-756 i-flat fillet welding ngaphambi nasemva kokususwa kwe-slag (AC)

I-GEL-756 i-flat fillet welding ngaphambi nasemva kokususwa kwe-slag (DC+))

Q690 intsimbi welding intonga yokhuseleko

1. Ukugcinwa kwe-welding consumables:

I-welding consumables iyacetyiswa ukuba igcinwe phantsi kobushushu obungapheliyo kunye neemeko ezomileyo, kwaye zibekwe kwiipalati okanye kwiishelufu, zigweme ukudibanisa ngqo neendonga kunye nomhlaba.

2. Amalungiselelo phambi kokuba welding:

Susa ngokucokisekileyo umswakama, i-rust, i-oyile ye-oyile, njl.njl kumphezulu wezinto ezisisiseko, kwaye ugweme umswakama ongaphezulu okanye ukuvezwa kwemvula kunye nekhephu.

3. Amanyathelo angangeni moya:

Xa udibanisa, kufuneka kuqinisekiswe ukuba isantya esiphezulu somoya kwindawo ye-welding ayidluli i-2m / s. Ngaphandle koko, amanyathelo okukhusela kufuneka athathwe.

4. Ukufudumeza:

Kunconywa ukusebenzisa izixhobo zokufudumeza zombane ukufudumeza i-workpiece ukuya ngaphezulu kwe-150 ° C ngaphambi kwe-welding. Kwanangaphambi kokuba kufakwe i-welding, kufuneka ifudunyezwe ibe ngaphezulu kwe-150°C.

5. Umaleko kunye nolawulo lobushushu bendlela:

Ngethuba lenkqubo ye-welding, iqondo lokushisa le-interpass akufanele libe ngaphantsi kwe-preheating, kwaye iqondo lokushisa eliphakanyisiweyo liyi-150-220 ° C.

6. Ukususwa kweHydrojeni emva kwe-welding:

Emva kokuba i-weld seam idityanisiwe, nyusa ngoko nangoko ubushushu bobushushu bombane ukuya kuma-250 ℃ ~ 300 ℃, yigcine ishushu iiyure ezi-2 ukuya kwezi-4, emva koko upholise kancinci.

① Ukuba ubukhulu be-workpiece yi-≥50mm, ixesha lokubamba kufuneka landiswe kwiiyure ezi-4-6, kwaye emva koko lipholiswe kancinci.

② Phantsi kweemeko zobukhulu obukhulu kunye nokuthintela okukhulu, enye enye i-dehydrogenation inokudityaniswa emva kwe-welding ukuya kwi-1/2 ubukhulu, kwaye ipholile ngokukhawuleza kwiqondo lokushisa.

7. Uyilo lomgangatho:

Kunconywa ukusebenzisa i-multi-layer kunye ne-multi-pass welding, kwaye isantya se-welding kufuneka sigcinwe kwisantya esiqhubekayo.

More information send to E-mail: export@welding-honest.com

Ixesha lokuposa: Jan-10-2023