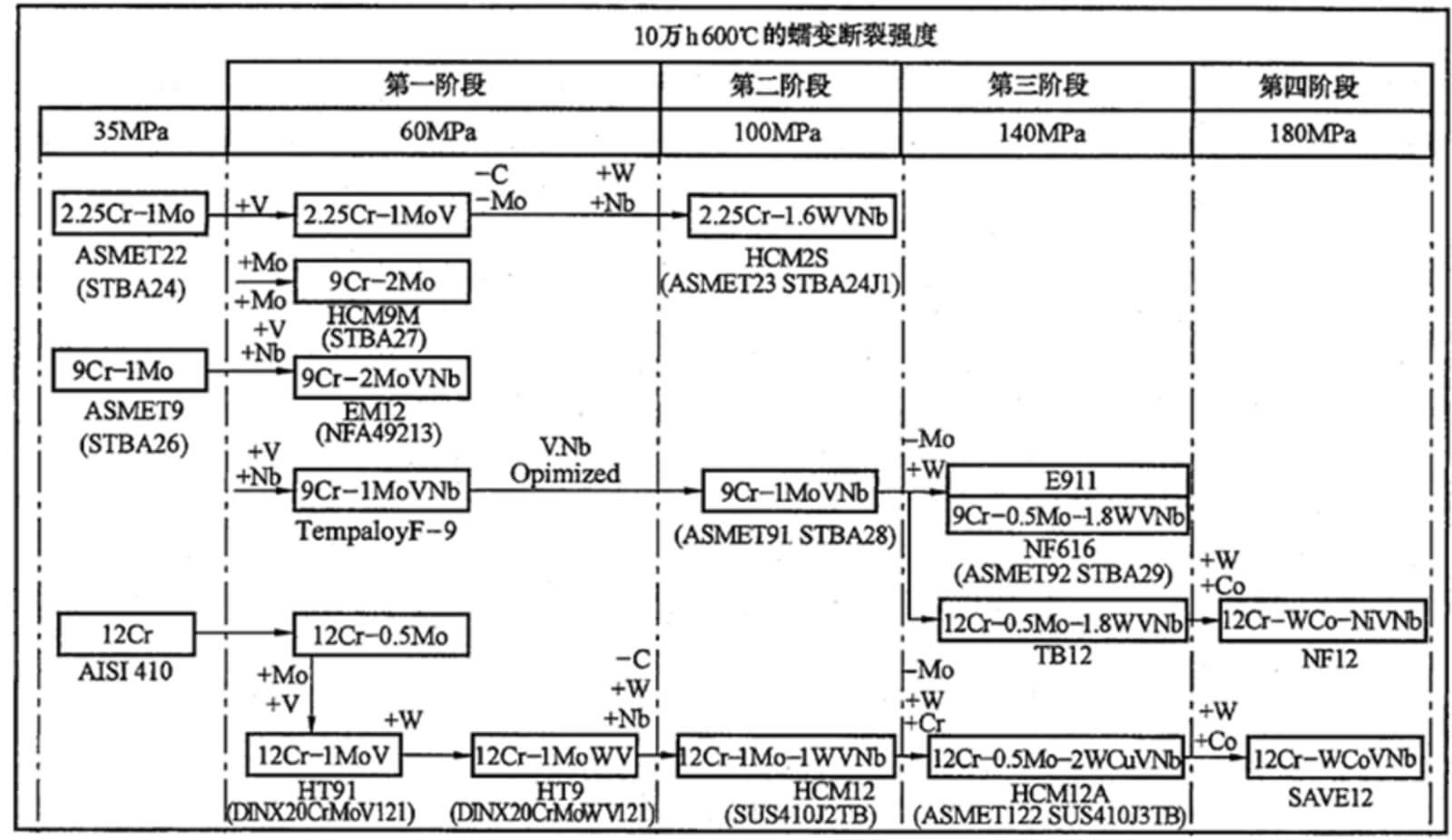

Ukuphuhliswa kwentsimbi ye-ferritic enganyangeki ukushisa

Ukwandisa i-Cr-1.25Cr ukuya kwi-12Cr

Yongeza u-V, Nb, Mo, W, Co, njl.

Indlela yoPhuhliso yentsimbi ye-ferritic enganyangeki ukushisa

Phawula:

Ngokwenkqubo yamazwe ngamazwe, izinto ezibizwa ngokuba yi-pearlite, bainite, kunye ne-martensitic ekwazi ukumelana nobushushu kwi-boiler kunye neentsimbi zemibhobho ngokudibeneyo zibizwa ngokuba "ziintsimbi ze-ferritic ezimelana nobushushu".

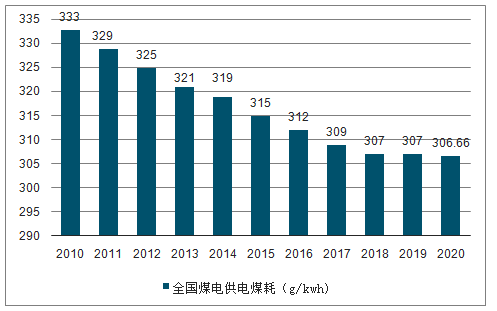

Ngokuhlengahlengiswa kolwakhiwo lwamandla elizwe lam kunye nokwandiswa kolwakhiwo lombane, ukusebenza kakuhle, ukucoceka, kunye nokusingqongileyo komthamo omkhulu kunye neeyunithi eziziiparamitha eziphezulu ziye zalawula. Ngokunyusa iiparamitha ze-steam (uxinzelelo kunye nobushushu), inokuphucula ngokufanelekileyo ukusebenza kwe-thermal yeyunithi, ukunciphisa ukusetyenziswa kwamalahle, kunye nokunciphisa ukukhutshwa kwe-CO2. Okwangoku, indlela ephambili yokuphucula ukusebenza kakuhle kweeyunithi zamandla ashushu kukuphucula iiparamitha ze-steam kunye nokuphuhlisa i-supercritical (SC) kunye ne-ultra-supercritical (USC) iiyunithi. Okwangoku, kukho ngaphezu kwe-100 yezigidi-ye-kilowatt ultra-supercritical (USC) iiyunithi ezifakwe ekusebenzeni kwilizwe lam, zibekwe kwindawo yokuqala kwihlabathi kubuninzi kunye nomthamo opheleleyo.

Iinkcukacha-manani kunye noQhekelelo lokuSetyenziswa koMbane wamalahle e-China ukusuka ngowama-2010 ukuya kowama-2020.

2.IiMveliso ezingundoqo ze-Chromium Molybdenum Steel Welding Rod

Itheyibhile yesi-2 Umboniso wokusebenza we-electrode yentsimbi emele i-pearlitic

| Into | Isithako esiphambili | Ubushushu℃*H | Indlela yokuziphatha koomatshini | ||||

| Yima kancinci Mpa | Ukuqina Mpa | Yandisa % | Umothuko J/℃ | ||||

| I-GER-107 | 0.5% Mo | 620*1 | 477 | 570 | 24.0 | 152/0 | - |

| I-GER-207 | 0.5%Cr-0.5%Mo | 690*1 | 490 | 590 | 23.0 | 143/0 | - |

| IGER-307 | 1.25%Cr-0.5%Mo | 690*1 | 490 | 590 | 23.0 | 146/0 | - |

| IGER-317 | 1.25%Cr-0.5%Mo-V | 730*2 | 541 | 635 | 22.5 | 166/0 | - |

| IGER-407 | 2.25%Cr-1%Mo | 690*1 | 586 | 682 | 21.0 | 142/0 | - |

| IGER-417 | 2.25%Cr-1%Mo-V | 720*8 | 556 | 657 | 21.0 | 145/-18 | 120/-30 |

| IGER-507 | 5%Cr-0.5%Mo | 740*1 | 490 | 605 | 23.0 | 124/0 | - |

Phawula:

1. Inkampani yethu iphuhlise i-EXXXX-15, i-EXXXX-16, i-EXXXX-18 kunye nolunye uchungechunge lwe-slag yokwambathisa kwii-electrode zebakala elifanayo ukuhlangabezana neemfuno zeemarike ezahlukeneyo. Oku ngasentla kubonisa kuphela ukusebenza kwee-electrode ze-EXXXX-15.

3.2 Uluhlu lwe-subcritical kunye ne-super (ultra) ebalulekileyo ye-ferritic / martensitic i-electrode yensimbi ekwazi ukumelana nobushushu

| INTO | UMGANGATHO | Umlinganiswa oPhambili |

| IGER-707 | AWS A5.5 E8015-B8 GB/T 5118 E6215-9C1M | I-9% ye-Cr-1% ye-Mo Carbon steel core wire, i-alloy composition engundoqo iguqulwa ukusuka kwi-coating, ilungele i-thermal power subcritical units, i-A213-T9, i-A335-P9 yensimbi ye-welding (uqoqosho kunye nokusebenza kakuhle, ukusebenza kakuhle) |

| IGER-91 Uhlobo olungundoqo | AWS A5.5 E9015-B91 GB/T 5118 E6215-9C1MV | I-9% Cr-1% i-Mo-Nb-vn Ifanelekile kumandla okushisa amashishini abalulekileyo, i-T / P 91 ye-welding yensimbi, ukubunjwa kwe-alloy engundoqo idluliselwa kwi-welding core, i-microstructure ephezulu yokushisa kunye nokuzinza kokusebenza. |

| I-GER-91M iziyobisi ulusu core | I-9% Cr-1% ye-Mo-Nb-VN Ifanelekile kumandla okushisa amashishini abalulekileyo, i-T / P 91 yensimbi yentsimbi, ukubunjwa kwe-alloy engundoqo idluliselwa kwi-welding core, i-microstructure ephezulu yokushisa kunye nokuzinza kokusebenza. | |

| IGER-92 Uhlobo olungundoqo | AWS A5.5 E9015-B92 | I-9% Cr-0.5% Mo-WV-Nb-N Ifanelekile kwiiyunithi ze-thermal supercritical power units, i-T / P 92 yensimbi ye-welding, i-alloy composition engundoqo iguqulwa ukusuka kwi-core wire, i-microstructure ephezulu yokushisa kunye nokuzinza kokusebenza. |

| IGER-93 | Umgangatho wethu | I-9% Cr-3% W-3% Co-Cu-V-Nb-B Ifanelekile ukuwelda kwentsimbi ephezulu ephezulu ye-G115 ephezulu yokuvelisa amandla ashushu. Inesakhiwo esihle kunye nokuzinza kokusebenza kwiqondo lokushisa eliphezulu. Amandla ahlala ixesha elide le-1.5 yentsimbi ye-P92, kwaye ukuchasana kwayo ne-oxidation yobushushu obuphezulu kunye ne-corrosion kungcono kune-P92 yensimbi. |

Umboniso wokusebenza kwe-Electrode

| Into | Isithako esiphambili | Ubushushu℃*H | Indlela yokuziphatha koomatshini | |||

| Yima kancinci Mpa | Ukuqina Mpa | Yandisa % | Umothuko J | |||

| IGER-707 | 9%Cr-1%Mo | 740*1 | 540 | 670 | 24.0 | 119.7 |

| IGER-91 | 9%Cr-1%Mo-Nb-VN | 760*2 | 557 | 702 | 21.0 | 96.3 |

| I-GER-91M | 9%Cr-1%Mo-Nb-VN | 760*2 | 553 | 701 | 22.5 | 81.0 |

| IGER-92 | 9%Cr-0.5%Mo-WV-Nb-N | 760*2 | 596 | 706 | 21.5 | 103.0 |

| IGER-93 | 9%Cr-3%W-3%Co | 770*4 | 580 | 720 | 20.0 | 77.7 |

Phawula:

1. I-GER-91M i-coating transition, oko kukuthi, i-welding core yintsimbi eqhelekileyo ye-carbon steel core, kwaye i-alloy ephambili iguqulwa ngokugubungela. Xa kuthelekiswa ne-GER-91 (uhlobo olungundoqo lwe-wire transition), ineenzuzo ezingcono zezoqoqosho kwaye iyona yethu ephezulu Iimveliso eziphambili ze-welding rods zamandla ashushu aphezulu.

3.Inguqulo ye-ASME ye-2015 idinga i-E9015-B91 i-electrode Mn + Ni≤1.4%, kwaye inguqulo ye-2017 idinga ≤1.2% kwisiseko sesinyithi. (2021 inguqulelo yamva nje ye-ASME iyaqhubeka nokusebenzisa inguqulelo ka-2015 yeemfuno zokuqulunqwa kwe-ASME ye-E9015-B91/ B92 electrode). Ukuze kuhlangatyezwane nemfuno yemarike, i-E9015-B91 yethu kunye ne-E9015-B92 i-welding rods ziye zavelisa iintlobo ezimbini zezinto ezihambelanayo ze-welding: Mn + Ni≤1.4% kunye ne-Mn + Ni≤1.2%. Ngenxa yokuba lo mva unemfuno engaphezulu yeemarike, oku ngasentla kubonisa i-91/ 92 electrode ifakwe isinyithi i-Mn + Ni≤1.2%.

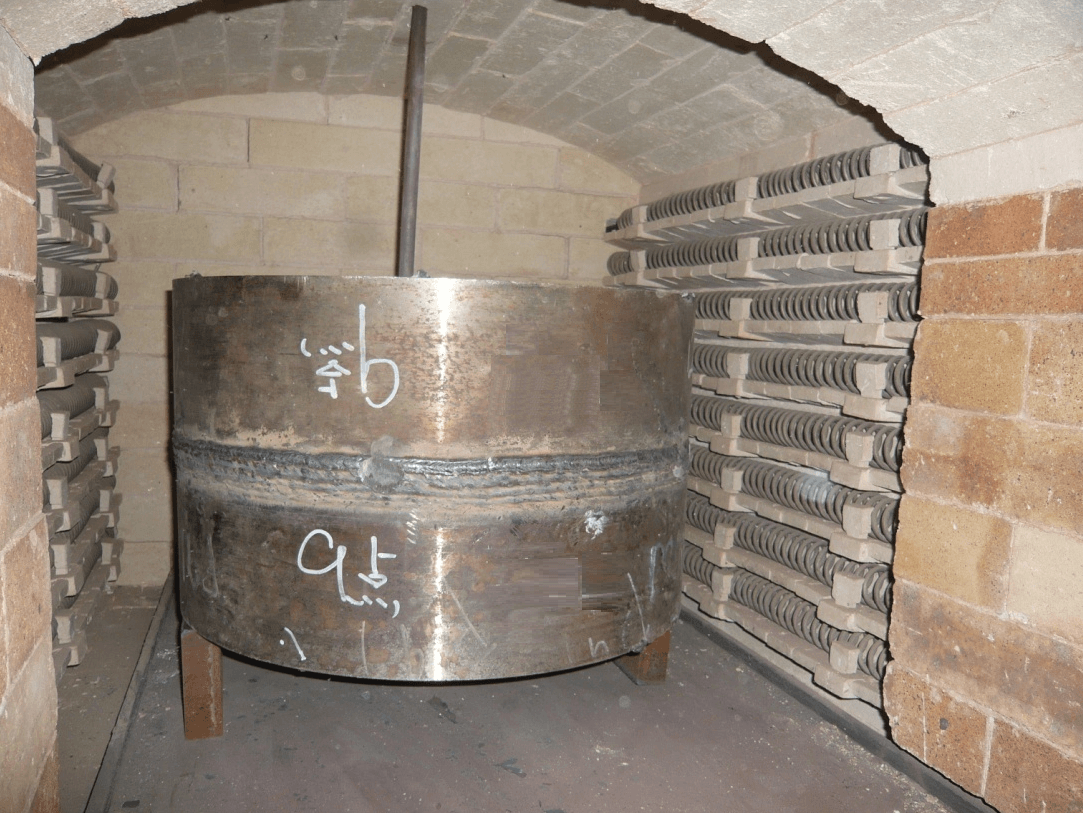

4. Umboniso wovavanyo lwenkqubo yee-electrode ze-ultra-supercritical

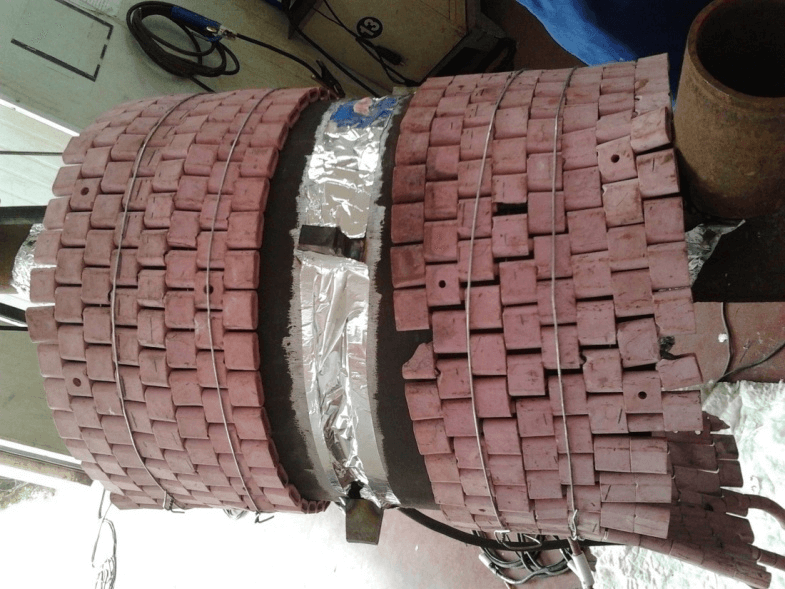

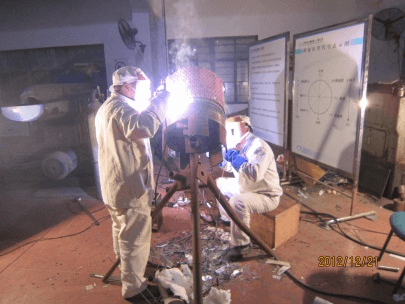

4.1 Inkqubo yesiqinisekiso seP91/92 ezidityanisiweyo ezidityanisiweyo

6. Izinto eziluncedo kunye neempawu zee-electrode zethu zetsimbi ezinganyangekiyo kwintsimbi ye-chrome-molybdenum

1. Kukho iintlobo ezininzi kunye nazo zonke iintlobo

●Ukwakheka kususela kwi-0.5%Mo ukuya kwi-9%Cr-3%W-3%Co.

●Sebenzisa amaqondo obushushu ukusuka 500℃ ukuya 650℃.

● Imibala eyohlukeneyo yokugquma kunye neentlobo zokugquma (EXXXX-15, EXXXX-16, EXXXX-18) zingasetyenziswa kwiimeko ezahlukeneyo (uhlobo ngokubanzi, uhlobo oluqinileyo lwe-arc lwemibhobho yokwakha amandla).

● Iyakwazi ukuhlangabezana neemfuno ze-welding ezininzi ze-Cr-Mo steels.

2. Ukusebenza kakuhle

Iipropathi ezigqwesileyo zomatshini, ukusebenza kakuhle kobushushu obuphezulu (ubushushu obuphezulu bokukhwela kunye neempawu zokuguga eziphezulu).

3. Ubugcisa obuhle

I-electrode ine-manufacturability egqwesileyo kuzo zonke izikhundla, ukutsha kwe-arc okuzinzile, ukuqina okulungileyo kunye namandla okuvuthela, i-spatter encinci, i-fluidity enhle, i-weld shape enhle, kunye nokususwa kwe-slag ngokulula emva kwe-welding.

4. Ishishini elikhokelayo

Ibambisene neSuzhou Institute of thermal Engineering, kwaye iphumelele uphononongo lwe "T / P 91/92 Localization Appraisal Meeting" ngo-2015, kwaye isebenzisana neeyunithi ezinkulu zamandla zasekhaya ezifana ne-Shenhua Guohua kunye ne-General Iron kunye ne-Steel Research Institute ukuphuhlisa i-650 ° C. I-G115 yentsimbi exhasa izixhobo ze-welding kunye neenkqubo, kwaye ibambe iintlanganiso ezininzi zokutshintshiselana kwezinto ezityiwayo.

More information send to E-mail: export@welding-honest.com

Ixesha lokuposa: Dec-27-2022