I. Isishwankathelo

Ngophuhliso olukhawulezayo lweekhemikhali zamazwe ngamazwe kunye nezixhobo zamandla, iitanki zokugcina insimbi engenasici kunye nezikhongozeli zisetyenziswa ngokubanzi ekuthuthweni nasekugcinweni kweekhemikhali, ukutya kunye nesiselo, amandla kunye nezinye izinto. Ngenxa yokuqina kwayo okuphantsi kobushushu obuphantsi kunye nokumelana ne-corrosion, i-austenitic steel stainless isetyenziswa ngokubanzi ekwakhiweni kweitanki zokugcina i-cryogenic, izixhobo kunye nezakhiwo ezinkulu ze-cryogenic.

Itanki yokugcina i-Cryogenic

2.Intshayelelo emfutshane yethu -196 ℃ ifuthe eliphantsi lobushushu obunefuthe kwizinto zokuwelda zentsimbi

| Udidi | Igama | Umzekelo | Umgangatho | Phawula | |

| GB/YB | AWS | ||||

| I-Electrode | I-GES-308LT | A002 | E308L-16 | E308L-16 | -196℃≥31J |

| Flux ucingo | GFS-308LT | - | TS 308L-F C11 | E308LT1-1 | -196℃≥34J |

| Ucingo oluqinileyo | I-GTS-308LT (TIG) | - | H022Cr21Ni10 | I-ER308L | -196℃≥34J |

| I-GMS-308LT (MIG) | - | H022Cr21Ni10 | I-ER308L | -196℃≥34J | |

| WABONA | GWS-308/ GXS-300 | - | S F308L FB-S308L | I-ER308L | -196℃≥34J |

3.I-electrode yethu ye-GES-308LT (E308L-16)

Ukuze kuhlangatyezwane nemfuno yemarike, inkampani yethu iphuhlise ubushushu obuphantsi be-ultra-low, ubunzima obuphezulu be-austenitic steel stainless steel electrode, ukubunjwa kweekhemikhali zentsimbi egciniweyo (njengoko kubonisiwe kwiThebhile 1) kunye neepropati ezizinzileyo (njengoko kubonisiwe kwiThebhile. 2), kwaye ineegqwesileyo zonke-indawo ukuwelda inkqubo Performance, kwaye ebalaseleyo ubushushu obuphantsi ifuthe ukuqina, impembelelo yemali yayo ferrite kwixabiso lempembelelo (Itheyibhile 3).

1.Ukubunjwa kweChemical yentsimbi egciniweyo

| E308L-16 | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | N | Fn |

| QAPHELA (%) | 0.04 | 0.5-2.5 | 1.0 | 0.030 | 0.020 | 9.0-12.0 | 18.0-21.0 | 0.75 | 0.75 | - | - |

| Isampulu1 | 0.022 | 1.57 | 0.62 | 0.015 | 0.006 | 10.25 | 19.23 | 0.020 | 0.027 | 0.046 | 6.5 |

| Isampulu2 | 0.037 | 2.15 | 0.46 | 0.018 | 0.005 | 10.44 | 19.19 | 0.013 | 0.025 | 0.45 | 3.8 |

| Isampulu3 | 0.032 | 1.37 | 0.49 | 0.017 | 0.007 | 11.79 | 18.66 | 0.021 | 0.027 | 0.048 | 0.6 |

Uluhlu loku-1

2.Iimpawu zeMechanical zetsimbi ezigciniweyo

| E308L-16 | Yima kancinci MPa | Ukuqina MPa | Ukwandisa % | -196℃Impembelelo J/℃ | I-GB/T4334-2020 E I-Intergranular corrosion | Rukuhlolwa kwe-adiographic | Phawula | |

| Ixabiso elinye | Ixabiso eliphakathi | |||||||

| NB | - | 510 | 30 | - | - | - | I | - |

| Isampulu1 | 451 | 576 | 42 | 32/32/33 | 32.3 | ufanelekile | I | - |

| Isampulu2 | 436 | 563 | 44 | 39/41/39 | 39.7 | ufanelekile | I | - |

| Isampulu3 | 412 | 529 | 44.5 | 52/53/55 | 53.3 | ufanelekile | I | - |

Itheyibhile 2

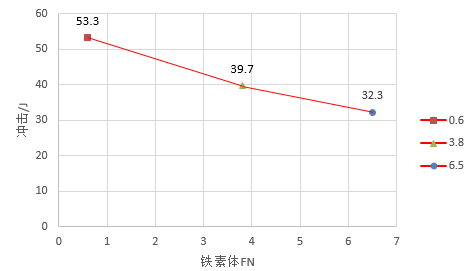

3.Isiphumo sesixa se-ferrite yentsimbi efakwe kwimpembelelo

4.Umboniso wenkqubo ye-welding (φ3.2mm)

Ukuwelda okuthe tye phambi nasemva kokususwa kwe-slag (DC+)

Ukuwelda kwemibhobho ngaphambi nasemva kokususwa kwe-slag (DC+)

4. Izilumkiso ze-welding ethe nkqo

1. I-welding ephantsi yangoku kufuneka isetyenziswe;

2. Gcina i-arc iphantsi kangangoko;

3. Xa i-arc ijika kumacala omabini e-groove, yima ixesha elithile, kwaye ububanzi be-swing bulawulwa ngaphakathi kwamaxesha ama-3 ububanzi be-electrode.

5.Umfanekiso wombhobho we-welding consumables application

Kwi -196 ℃ ifuthe eliphantsi lobushushu obuphantsi kwempembelelo yentsimbi yentsimbi etyiwayo, emva kweminyaka yophando kunye nophuhliso lwezinto ezityiwayo zokuwelda, sele sinezixhobo ezixhasayo ezixhasayo zokuwelda, ii-cores eziqinileyo, ii-flux cores kunye nee-arcs ezintywilweyo, kwaye siphuhlise i-electrode eqhubekayo ye-arc. iWelding Consumables kuyo yonke indawo-welding, kwaye ineempumelelo ezininzi zesicelo sobunjineli, bamkelekile abathengi ukuba babonisane kwaye bakhethe!

Ixesha lokuposa: Dec-16-2022