I-MIG Welding Wire ye-Stainless Steel ER430LNb inqanawa yempahla yokuwelda ikhoyili yocingo

I-TEKNOLOJI YOKUSHISA

Ungavumeli imibuzo

Qhubeka ukukukhathaza

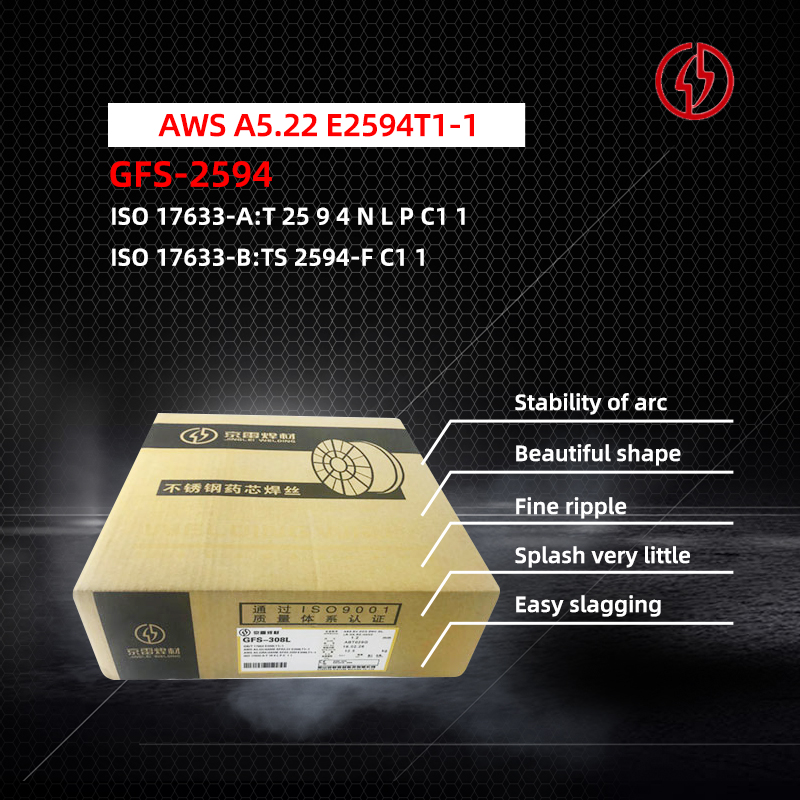

Ukungazinzi kweArc

Ukubumba okungathandekiyo

Isitshizi esigqithisileyo

Ilungele ukuwelda kohlobo lwe-17Cr yensimbi engenasici,

kodwa ifanelekile kwi-welding yokuvelisa

ukumelana ne-oxidation kunye nezixhobo zokuxhathisa ukubola

Okufana nokuwelda kwamacandelo enkqubo yesithulisi (njenge-430, 436, njl.).

Ripple kakuhle

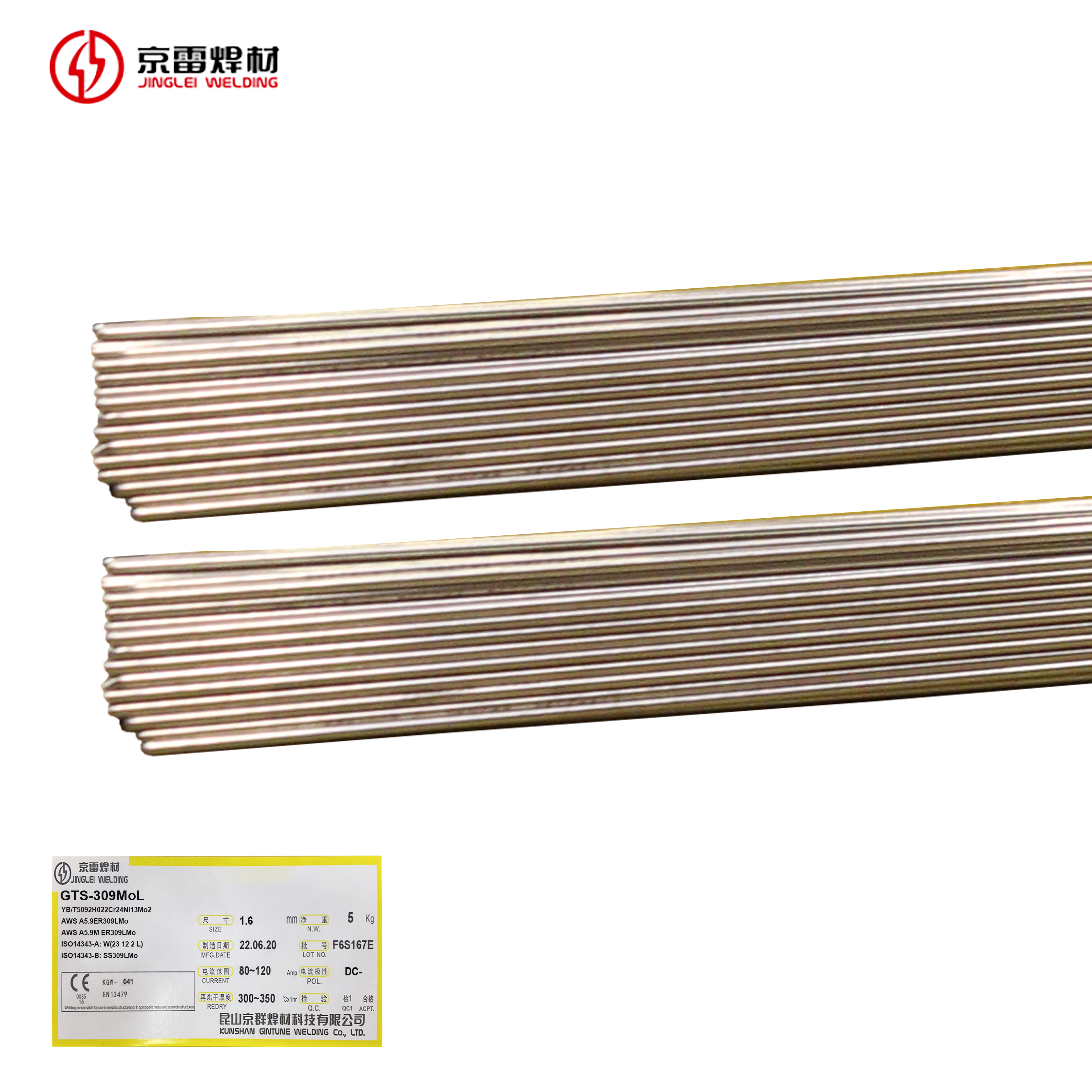

Iimpawu zomatshini we-fused

Isinyithi sizinzile, izinga le-X-Ray elifanelekileyo liphezulu

Ukutya kocingo kugudile, i-arc izinzile, ukubunjwa kuhle,

i-spatter incinci, kwaye inkqubo ye-welding inomsebenzi obalaseleyo.

Easy slagging

IParameter yeMveliso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Okunye |

| GB/T IMIGAQO | 0.016 | 0.9 | 0.5 | 0.024 | 0.005 | 0.35 | 17.54 | 0.01 | - |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | Ubude/% | IXABISO LE-IMAPACT J/℃ | Unyango lobushushu °C*h | |||||

| GB/T IMIGAQO | - | 475 | 28 | - | 780*2 | |||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 0.8 | 1.0 | 1.2 | ||||

| UMBANE (Amp) | H/W | 70-150 | 100-200 | 140-220 | |||

| O/W | 50-120 | 80-150 | 120-180 | ||||

Inkxaso yefektri

Imveliso ifanelekile a

uluhlu olubanzi lwezicelo

I-TEKNOLOJI YOKUSHISA

Ibhoyila eluncedo

981 isemi-submersible rig yokomba

Itanki yesitofu yokhuseleko

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Okunye |

| GB/T IMIGAQO | 0.016 | 0.9 | 0.5 | 0.024 | 0.005 | 0.35 | 17.54 | 0.01 | - |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | Ubude/% | IXABISO LE-IMAPACT J/℃ | Unyango lobushushu °C*h | |||||

| GB/T IMIGAQO | - | 475 | 28 | - | 780*2 | |||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 0.8 | 1.0 | 1.2 | ||||

| UMBANE (Amp) | H/W | 70-150 | 100-200 | 140-220 | |||

| O/W | 50-120 | 80-150 | 120-180 | ||||