I-ISO 3581-A Iintsimbi ezingenazintsimbi ezisetyenziswa ngesandla kwi-electrode ye-Welding

Isicelo&Mgangatho&Qaphela:

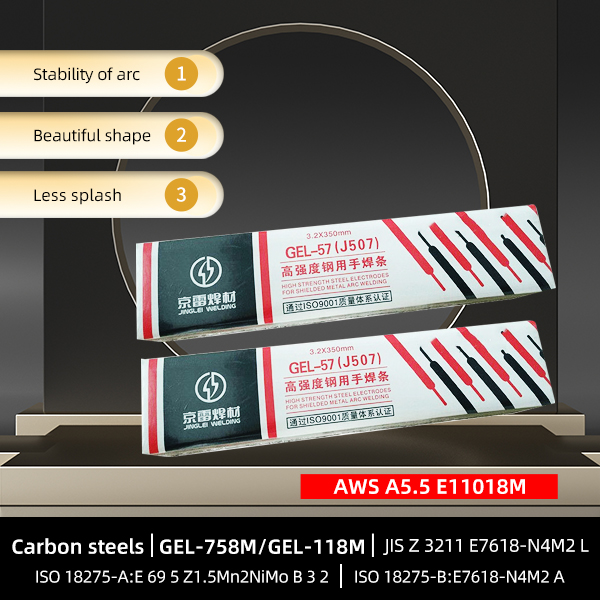

1. Ifanele UKUSHIYWA KWESITIMI ESIKABHABHONI KUNYE NENTENYE YE-ALLOY EPHANTSI, KWAKUNYE NAMANDLA OKUFANELEKILEYO WEBOILER, umbhobho, isithuthi, i-BUILDING, BRIDGE KUNYE NEZINYE IZIQULATHO, ezifana ne-Q345.

2. Umgangatho esidibene nawo: GB/T5117 E5016, AWS A5.1 E7016 & A5.1M E4916, ISO2560-A:E 42 3 B 1 2, ISO 2560-B: E4916 A

Imiqathango ye-welding:

Ngaphambi kwe-welding, i-weldment kufuneka ingabikho ngokupheleleyo kwioli, i-rust, umswakama, njl.; ukomisa kwi-350 ° C ngeyure; kunye nokumisa ngokusetyenziswa

3. Sebenzisa i-welding yokudlula emxinwa kunye ne-arc welding emfutshane; Uqhagamshelo lwe-AC kunye ne-DC umva.

Ingasetyenziselwa ukuwelda intsimbi yekhabhoni ephantsi kunye ne-490MPa yamandla aphezulu entsimbi yombhobho wentsimbi edibeneyo, inokuqonda ukuwelda kwecala elinye lokubumba kabini.

I-electrode yeyohlobo oluphantsi lwe-hydrogen, umbhobho we-welding kunye nesakhiwo ngokubanzi sengcambu ye-weld, inokuqonda i-welding yecala elinye-macala amabini, ngoko inokugcina isithende se-welding yokucoca, ukwenzela ukuba ukusebenza kakuhle kwe-welding kuphuculwe. .

Amanqaku aphambili enkqubo:

1, ukomisa ngaphambi kokusetyenziswa, 300 ~ 350 ℃ ukomisa imizuzu engama-30 ~ 60;

I-2, khetha i-current efanelekileyo kunye ne-groove, ukuze ufumane i-weld back weld;

3. Xa ucima i-arc, khokela umgodi we-arc kwicala le-groove uze uphule i-arc;

4. Ixesha lokuqala le-arc usebenzisa i-arc yokuqalisa ipleyiti okanye kwicala le-groove arc;

5. Gcina i-arc i-welding emfutshane;

6. Sebenzisa uqhagamshelo lwe-AC okanye lwe-DC.

Iimbonakalo

1. I-Titanium calcium i-electrode yensimbi engenasici, ukubunjwa okuphambili ngu-18% CR-8% Ni-6% Mn;

2. I-arc ezinzileyo, ukubunjwa okuhle, ama-ripples amahle, i-splashes embalwa, i-de-slagging elula, ukumelana nomlilo okulungileyo kwesikhumba samachiza, ukuxhathisa okulungileyo kwesisu.

3. Iimpawu ezizinzileyo zomatshini, izinga lokupasa kwe-X-reyi liphezulu.

E307-16with Grade (AWS A5.4),Stainless steel welding I-Electrode luhlobo olwahlukileyo lwentsimbi yokuwelda njenge-welding austenitic manganese kwi-carbon steel castings okanye i-forgings.

Zisetyenziswa kakhulu kwishishini lezicelo ezahlukeneyo kwaye zenziwe ngetekhnoloji ye-urbane kunye nenqanaba eliphezulu lemathiriyeli ekrwada eneempawu ezintsha, Ezi electrode zokuwelda ze-SS zisenokwenziwa ngokwesiko ngokunxulumene nobukhulu kunye nobukhulu bazo ngokweemfuno zabathengi.

Inkampani kunye neFactory

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T IMIGAQO | 0.20 | 4.5-7.5 | 1.20 | 17-20 | 44752.00 | 0.75 | 0.035 | 0.03 | 0.75 |

| I-AWS IMIGAQO | - | - | - | - | - | - | - | - | - |

| UMZEKELO IXABISO | 0.071 | 5.58 | 1.03 | 19.12 | 8.9 | 0.2 | 0.028 | 0.006 | 0.012 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | |||||||||

| GB/T IMIGAQO | 350 | 500 | - | - | 25 | |||||||||

| I-AWS IMIGAQO | - | - | - | - | - | |||||||||

| UMZEKELO IXABISO | - | 635 | - | - | 36 | |||||||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| UMBANE (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

IINKCUKACHA ZOKUPAKA:

| UKWAHLUKANA | UBUDE | PCS/1KG | Ubunzima/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

PHAWULA:

H / W: ukuwelda indawo ethe tye

O / W: phezu-intloko isikhundla welding

Amatyala aqhelekileyo

Isatifikethi

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T IMIGAQO | 0.20 | 4.5-7.5 | 1.20 | 17-20 | 44752.00 | 0.75 | 0.035 | 0.03 | 0.75 |

| I-AWS IMIGAQO | - | - | - | - | - | - | - | - | - |

| UMZEKELO IXABISO | 0.071 | 5.58 | 1.03 | 19.12 | 8.9 | 0.2 | 0.028 | 0.006 | 0.012 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | |||||||||

| GB/T IMIGAQO | 350 | 500 | - | - | 25 | |||||||||

| I-AWS IMIGAQO | - | - | - | - | - | |||||||||

| UMZEKELO IXABISO | - | 635 | - | - | 36 | |||||||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| UMBANE (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

IINKCUKACHA ZOKUPAKA:

| UKWAHLUKANA | UBUDE | PCS/1KG | Ubunzima/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

PHAWULA:

H / W: ukuwelda indawo ethe tye

O / W: phezu-intloko isikhundla welding