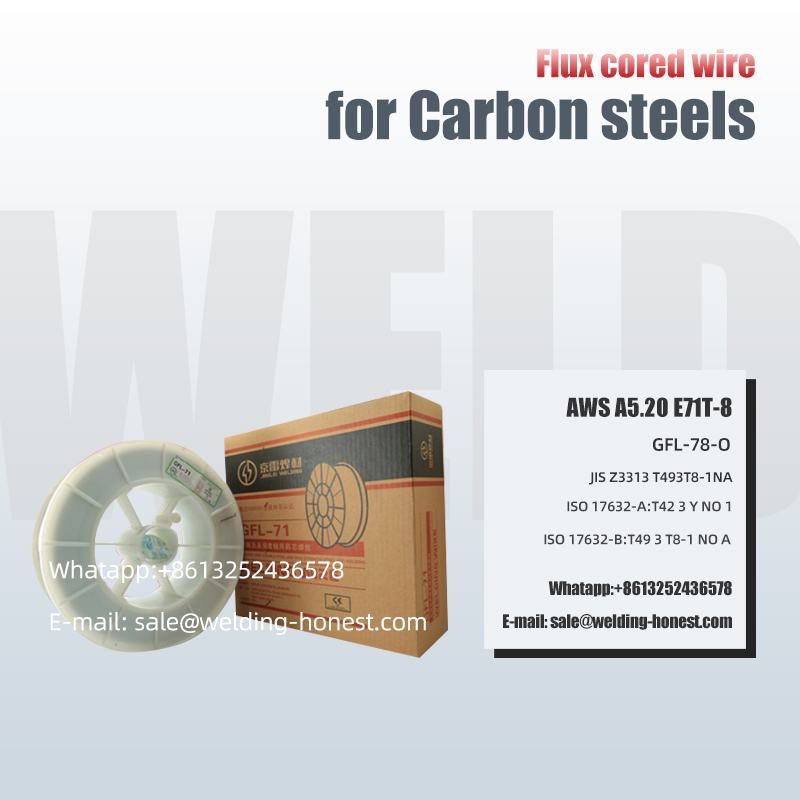

High Carbon steels Flux cored ucingo E71T-1M metal Ukudibanisa ukwenza

Ifanelekile ukuwelda iinqanawa, iiBridges, izakhiwo, iiplatifti ze-offshore, imibhobho, izakhiwo zetsimbi, njl.

Ziziphi iimpawu?

●I-arc ithambile kwaye izinzile, i-splash encinci, ibukeka kakuhle.

●Ukususwa kwe-slag elungileyo, uthuli oluncinci, kwaye inomsebenzi obalaseleyo wenkqubo ye-welding.

●Ukusebenza kwempembelelo yobushushu obuphantsi kuhle kakhulu.

IParameter yeMveliso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Okunye |

| GB/T IMIGAQO | 0.033 | 0.49 | 1.34 | 0.01 | 0.005 | 0.01 | 0.020 | 0.01 | - |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | IXABISO LE-IMAPACT J/℃ | Unyango lobushushu °C*h | ||||

| GB/T IMIGAQO | 495 | 555 | 26 | 120/-20 | - | ||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 1.2 | 1.4 | 1.6 | ||||

| IVolt | 23-32 | 24-36 | 25-40 | ||||

| Amp | 150-300 | 170-360 | 200-400 | ||||

| Ubude bokusolula okomileyo(mm) | 15-20 | 15-20 | 18-25 | ||||

| Ukuhamba kwerhasi(I/min) | 15-25 | 15-25 | 15-25 |

Indlela yothutho

●Uthutho lweemoto

●Ukuhambisa ngenqanawe

Indawo yethu yokugcina impahla

Sithatha inxaxheba kucwangciso

●Iitoni ezingama-308,000 zenqanawa yeoli ekrwada yeVLCC

Iimveliso zethu kwihlabathi

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Okunye |

| GB/T IMIGAQO | 0.033 | 0.49 | 1.34 | 0.01 | 0.005 | 0.01 | 0.020 | 0.01 | - |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | IXABISO LE-IMAPACT J/℃ | Unyango lobushushu °C*h | ||||

| GB/T IMIGAQO | 495 | 555 | 26 | 120/-20 | - | ||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 1.2 | 1.4 | 1.6 | ||||

| IVolt | 23-32 | 24-36 | 25-40 | ||||

| Amp | 150-300 | 170-360 | 200-400 | ||||

| Ubude bokusolula okomileyo(mm) | 15-20 | 15-20 | 18-25 | ||||

| Ukuhamba kwerhasi(I/min) | 15-25 | 15-25 | 15-25 |

Bhala umyalezo wakho apha kwaye uwuthumele kuthi