Iintsimbi zeCarbon eziPhakamileyo E12015-G yamandla ethylene spherical tank eyenziwe nge-07MnNiMo DR yentsimbi yokuthambisa

I-welding efanelekileyo kwiziphene zeenqwelo zesitimela ezenziwe ngeBanga E zensimbi nazo zingasetyenziselwa ukutshisa i-welding yezinga elifanayo eliphantsi kwe-alloying degree.

Yintoni na

ubunjani?

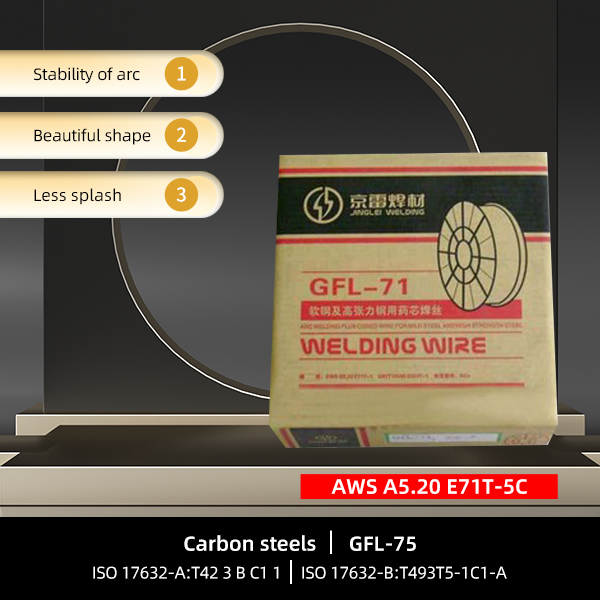

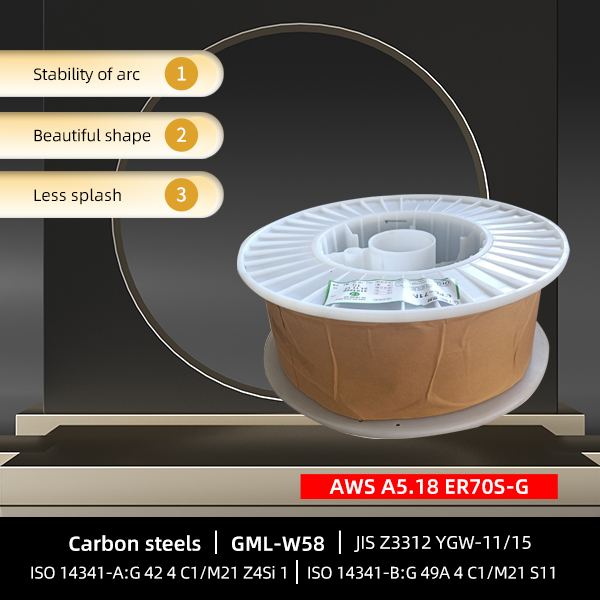

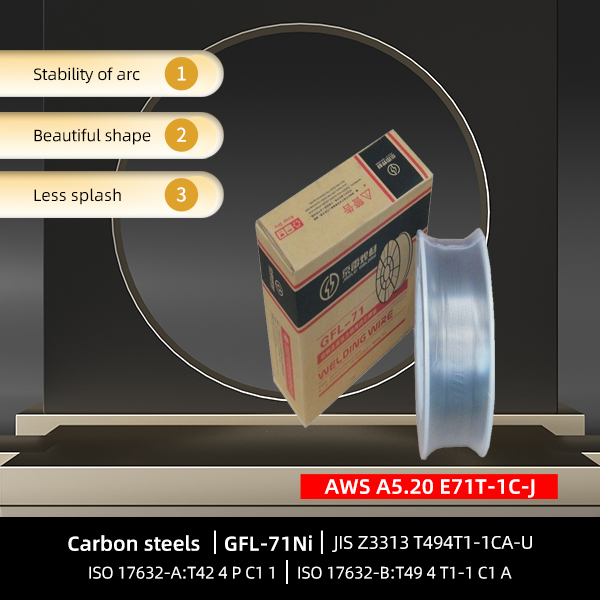

●I-sodium ephantsi ye-hydrogen uhlobo lwe-electrode yesandla.

●I-arc ezinzileyo, i-splash encinci, ukubunjwa okulungileyo, ukususwa kwe-slag ngokulula, ukusebenza kwe-X-Ray.

●Ukumelana nokuqhekeka okulungileyo, iipropati ezizinzileyo zoomatshini

●Ubushushu obuphantsi befuthe ubunzima.

IParameter yeMveliso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Okunye |

| GB/T IMIGAQO | 0.062 | 0.34 | 1.73 | 0.011 | 0.005 | 2.35 | 0.63 | 0.45 | - |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | IXABISO LE-IMAPACT J/℃ | Unyango lobushushu °C*h | ||||

| GB/T IMIGAQO | 760 | 860 | 19 | 49/-50 | - | ||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| UMBANE (Amp) | H/W | 55-85 | 90-130 | 130-180 | 180-240 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Indlela yothutho

●Uthutho lweemoto

●Ukuhambisa ngenqanawe

Indawo yethu yokugcina impahla

Sithatha inxaxheba kucwangciso

●I-400,000 yeetoni zomphathi we-ore

●Iitoni ezingama-9,000 zemichiza

Iimveliso zethu kwihlabathi

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Okunye |

| GB/T IMIGAQO | 0.062 | 0.34 | 1.73 | 0.011 | 0.005 | 2.35 | 0.63 | 0.45 | - |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | IXABISO LE-IMAPACT J/℃ | Unyango lobushushu °C*h | ||||

| GB/T IMIGAQO | 760 | 860 | 19 | 49/-50 | - | ||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| UMBANE (Amp) | H/W | 55-85 | 90-130 | 130-180 | 180-240 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Bhala umyalezo wakho apha kwaye uwuthumele kuthi