Ubuso obuqinileyo be-SAW welding wire kunye ne-welding flux weld fabrication fabrication

Usetyenziso & noMgangatho

Le electrode yesandla ye-WEAR enganyangekiyo yesandla ilungele ubukhulu becala impembelelo ephantsi, iindawo ezinxitywe kakhulu, ezinje ngoomatshini bokwakha bajongana nokuhlaziya, ngakumbi oomatshini bokutsala, iemele, impompo yokufunxa isanti. I-Surfacing yindlela ye-welding apho umphezulu okanye umgca weengxenye zetsimbi udityaniswe ngoluhlu lokunganyangeki, ukuxhatshazwa kwe-corrosion, ukumelana nokushisa okuphezulu kunye nezinye iimpawu zezixhobo zetsimbi. Ukulungisa nokuphucula ubomi benkonzo yamacandelo, ukusetyenziswa okusebenzayo kwezinto eziluhlaza, ukuphucula ukusebenza kwemveliso, ukulawulwa kweendleko kuneenzuzo ezicacileyo zezoqoqosho. Umgangatho wokujonga phezulu unzima kakhulu. Kuyimfuneko ukwamkela i-welding wire efanelekileyo ngokwemigaqo eyahlukeneyo. Iinkqubo ezahlukeneyo zokujonga umphezulu kufuneka zisetyenziswe kumacandelo entsimbi ahlukeneyo kunye ne-electrode engaphezulu ukuze kufumaneke iziphumo ezanelisayo zokwenyani.

Iimbonakalo

Olu luhlobo olusezantsi lwe-sodium ye-hydrogen yokwambathisa i-electrode ejongene ne-surfacing, ubunzima obuphezulu, akukho mfuneko yonyango lobushushu, ayinakuqhubeka nokusika, ukumelana nokunxiba kakuhle. Ukunxiba - inkqubo yokusebenza echanekileyo inokuqinisekisa ukuba lonke ulusu lunokunyibilika kwidama elinyibilikisiweyo nge-arc ngexesha lokudityaniswa kwe-welding. Kwaye i-weld core, i-substrate surface metal inyibilika ngokukhawuleza ukuvelisa i-alloy entsha ekwazi ukumelana nokunxiba. Ngelo xesha, iinzame kufuneka zenziwe ukuphucula umxholo wekhabhoni we-electrode kwisiseko sokuqinisekisa ukuba i-welding layer inokumelana nokuqhekeka okugqwesileyo. Ukukhuthaza ukubunjwa kwee-carbides ezahlukeneyo, ukwandisa ukuchasana kwayo. Kuba iindawo ezithwala impembelelo kunye nokunxitywa kwe-abrasive ngaxeshanye emsebenzini, njengentloko yehamile ye-crusher, i-lining plate, intonga ye-cage, njl. inkqubo yokusebenza eyahlukileyo ngokupheleleyo kufuneka yamkelwe.

Inkampani kunye neFactory

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | P | S |

| GB/T IMIGAQO | 0.50-0.80 | 0.50-1.50 | 1.00 | 4.00-8.00 | 0.035 | 0.035 |

| I-AWS IMIGAQO | - | - | - | - | - | - |

| UMZEKELO IXABISO | 0.64 | 1.35 | 0.94 | 7 | 0.027 | 0.007 |

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| UMBANE (Amp) | 80-120 | 120-160 | 160-210 | |||||

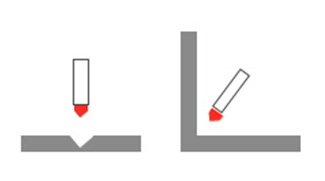

IMIXEKO EQHELEKILEYO

Izatifikethi

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | P | S |

| GB/T IMIGAQO | 0.50-0.80 | 0.50-1.50 | 1.00 | 4.00-8.00 | 0.035 | 0.035 |

| I-AWS IMIGAQO | - | - | - | - | - | - |

| UMZEKELO IXABISO | 0.64 | 1.35 | 0.94 | 7 | 0.027 | 0.007 |

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| UMBANE (Amp) | 80-120 | 120-160 | 160-210 | |||||