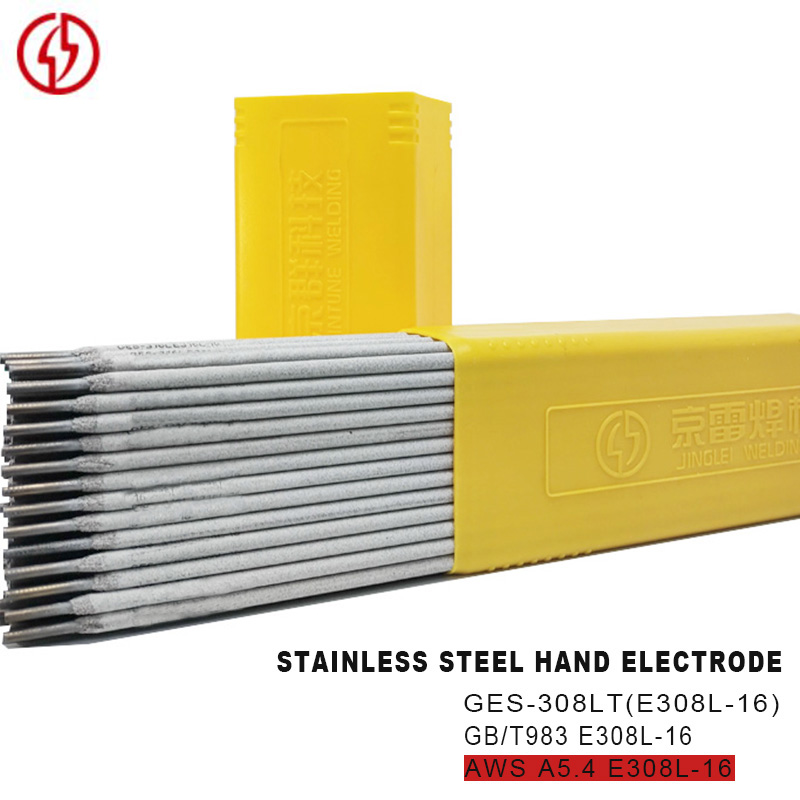

Ejongene nzima Manual electrode weld fabrication izinto

Usetyenziso & noMgangatho

I-GEH-547 i-electrode yesandla ekwazi ukumelana nobuso obuqinileyo isetyenziswa ikakhulu ukubeka phezu komhlaba kunye nokulungisa iindawo ezigugileyo zezixhobo zekhemikhali kunye nezixhobo ezahlukeneyo zoomatshini. Njengeendawo ezibuthathaka zeslag (ezifana nehamile yokutyumza, ipleyiti yehammer, ipleyiti yekhawuntara), isixhobo sokukhulula sesamente (itreyi, spire, grate), isixhobo somatshini wezitena, iblawudi zomxube, iiblawudi zomatshini wokukrazula, iiblades zefeni yeplanti yamandla, ukuqhushumba kwentsimbi yokusila. ipleyiti yokubeka i-chute yomlilo, i-roller, i-cone eyaphukileyo, umatshini wamalahle njalo njalo. Isiphumo sokujonga phezulu sibhekisa kubulukhuni, ukuxhathisa ukunxiba kunye nokumelana nobushushu bomaleko we-welding, kwaye ukusebenza kwayo kuhambelana nezi zinto zilandelayo:

1. Ubungakanani bangoku be-Welding, ubude be-arc. Inkulu yangoku, i-arc ende, i-alloying elements kulula ukutshisa, kungenjalo, i-alloying elements iguquguqukayo. 2. Ukushisa kwangaphambi kokushisa kunye neemeko zokupholisa ezicothayo zimisela umgangatho womgangatho we-surfacing layer. 3. Iindlela ezahlukeneyo zonyango lobushushu zingasetyenziselwa ukufumana ubulukhuni obahlukeneyo bezinye iintsimbi eziphezu komhlaba.

Iimbonakalo

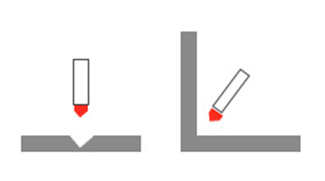

I-GEH-547 yi-sodium ephantsi ye-hydrogen uhlobo lwe-chromium-nickel butt welding electrode, ukusebenza kakuhle, ukuchaphaza okuncinci, kulula ukuphosa, ukumila okuhle, kulula ukwenza ukuqhutyelwa komatshini; Ukomelezwa kwe-silicon kwandisa ubulukhuni, ukuxhathisa kwe-abrasion, ukuxhathisa ukubola kunye nokumelana ne-oxidation yentsimbi engaphezulu. Eyona ngxaki ixhaphakileyo ekudibaneni nayo kwi-surfacing kukuqhekeka. Iindlela eziphambili zokuthintela ukuqhekeka zilandelayo: 1. Ukushisa ngaphambi kwe-welding, lawula ukushisa phakathi kweengqimba, ukupholisa ngokukhawuleza emva kwe-welding; 2. 2. Ukushisa unyango ukuphelisa uxinzelelo emva kwe-welding. 3, kunqanda ukuqhekeka kwemigangatho emininzi, usebenzisa i-electrode esezantsi yohlobo lwehydrogen. 4. Ngaphambi kwe-welding, kufuneka yomiswe kwi-300-350 ℃ ngeyure eli-1; Kufuneka ukususa izinto isiseko umphezulu ukufuma, amabala umhlwa, ioli, njl Kufuneka kwakhona ingqalelo indlela arc kunye arc.

Inkampani kunye neFactory

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | S |

| GB/T IMIGAQO | 0.18 | 0.60-2.00 | 4.80-6.40 | 15.00-18.00 | 7.00-9.00 | 0.04 | 0.030 |

| I-AWS IMIGAQO | - | - | - | - | - | - | - |

| UMZEKELO IXABISO | 0.05 | 1.26 | 5.34 | 16.8 | 7.78 | 0.028 | 0.006 |

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| UMBANE (Amp) | 80-120 | 120-160 | 160-210 | |||||

IMIXEKO EQHELEKILEYO

Izatifikethi

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | S |

| GB/T IMIGAQO | 0.18 | 0.60-2.00 | 4.80-6.40 | 15.00-18.00 | 7.00-9.00 | 0.04 | 0.030 |

| I-AWS IMIGAQO | - | - | - | - | - | - | - |

| UMZEKELO IXABISO | 0.05 | 1.26 | 5.34 | 16.8 | 7.78 | 0.028 | 0.006 |

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| UMBANE (Amp) | 80-120 | 120-160 | 160-210 | |||||