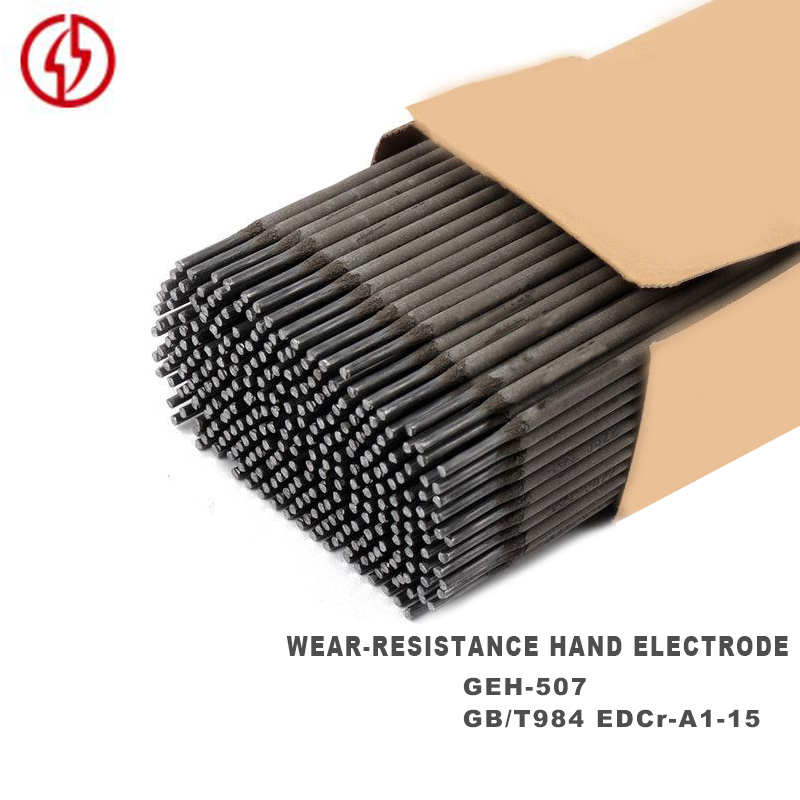

Ubuso obunzima bokwenza izixhobo ze-electrode weld manual

Usetyenziso & noMgangatho

I-GEH-547Mo yi-electrode yesandla ehambelana ne-GB/T984 ED CrNi-B-15, esetyenziswa kuzo zonke iintlobo ze-welding ye-surfacing kunye ne-metal surface welding. Isetyenziselwa ikakhulu ukuvela komphezulu woxinzelelo oluphezulu lwevalvu yokutywina kunye nobushushu obusebenzayo obungaphantsi kwama-600 ℃. Ngokujonga i-alloy ethile kumphezulu we-substrate, inokuhlangabezana neemfuno zokumelana nokunxiba kunye nokumelana nokubola. Ukumelana nokushisa okuphezulu okanye ukudibanisa kweemeko zokusebenza. Ingaba ukunciphisa iindleko zokuvelisa, ukuphucula ukusetyenziswa kwemveliso ngokulungiswa okuninzi, okanye ukuququzelela ukulawulwa kokwakhiwa kunye nokuma kwe-workpiece, iindlela ezifanelekileyo kakhulu kunye nezoqoqosho. I-teknoloji ebizwa ngokuba yi-hard surface yokunxiba iteknoloji idla ngokubizwa ngokuba yintsimbi, ukutshiza okanye ukulungiswa.

Iimbonakalo

I-GEH-547Mo yi-sodium ephantsi ye-hydrogen coated high chromium nickel valve i-electrode ejongene ne-electrode, esebenzisa i-DC reverse connection. Isinyithi esiphezu komhlaba siqiniswa yi-Si, Mo, W, V, Nb kunye nezinye izinto zokufumana isakhiwo se-autonitic kunye nexabiso elincinci le-ferrite, enokumelana nokushisa okuphezulu kwe-abrasion kunye nokumelana nokukhukuliseka, ubunzima obuphezulu bokushisa, ukuzinza okulungileyo kwe-thermal kunye ne-thermal. ukumelana nokudinwa. Ukuguga kwesiphumo sokuqina kwentsimbi kuyamangalisa. Ngokukhula kwexesha lokuguga, ukuqina kunye nokuxhathisa kwe-abrasion kuphuculwe ngakumbi. Ilungele ukubeka indawo yokutywina yevalve yoxinzelelo oluphezulu kunye nobushushu obusebenzayo obungaphantsi kwe-600 ℃, zonke iintlobo zegobolondo levalvu, isitulo sevalvu, ipleyiti yesango, intloko yevalve ephambili, undoqo womnyango wokhuseleko kunye nediski yevalvu, njl.

Inkampani kunye neFactory

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Nb | P | S |

| GB/T IMIGAQO | 0.18 | 0.60-5.00 | 3.80-6.50 | 14.00-21.00 | 6.50-12.00 | 3.50-7.00 | 0.50-1.20 | 0.04 | 0.03 |

| I-AWS IMIGAQO | - | - | - | - | - | - | - | - | - |

| UMZEKELO IXABISO | 0.05 | 1.26 | 5.34 | 16.1 | 8.1 | 3.8 | 0.61 | 0.028 | 0.007 |

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| UMBANE (Amp) | 80-120 | 120-160 | 160-210 | |||||

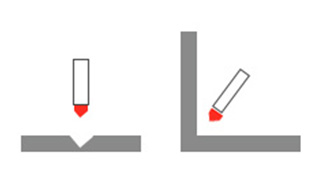

IMIXEKO EQHELEKILEYO

Izatifikethi

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Nb | P | S |

| GB/T IMIGAQO | 0.18 | 0.60-5.00 | 3.80-6.50 | 14.00-21.00 | 6.50-12.00 | 3.50-7.00 | 0.50-1.20 | 0.04 | 0.03 |

| I-AWS IMIGAQO | - | - | - | - | - | - | - | - | - |

| UMZEKELO IXABISO | 0.05 | 1.26 | 5.34 | 16.1 | 8.1 | 3.8 | 0.61 | 0.028 | 0.007 |

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| UMBANE (Amp) | 80-120 | 120-160 | 160-210 | |||||