I-AWS E7015-A1 Iintsimbi eziphantsi kwe-alloy Manual electrode Welding accessories

Isicelo&Mgangatho&Qaphela:

Uhlobo lwe-E7015 olusezantsi lwentsimbi yentsimbi ye-electrode ilungele ukuwelda ubushushu bokusebenza obungaphantsi kwe-510 ℃ umbhobho webhoyila, umtshintshi wobushushu kunye nezinye izihlandlo, njenge-ASTM A204 kunye ne-A335-P1 umbhobho;

I-electrode kufuneka yomiswe ngaphambi kokusetyenziswa, gcina i-arc emfutshane, ukusetyenziswa kwendlela yokubuyela ngasemva, ugweme ukwenzeka kwe-porosity kwi-arc; I-hydrogen ephantsi kufuneka igcinwe kuyo yonke inkqubo ye-welding. Ukukhethwa kwe-electrode yentsimbi ephantsi, ngokuqhelekileyo ngokwemichiza yentsimbi, iipropati zoomatshini, ukuxhathisa ukuqhekeka kunye nezinye iimfuno, kodwa nakwimilo yesakhiwo se-welding, iimeko zokusebenza, uxinzelelo kunye nezixhobo ze-welding kunye neminye imiba yokuqwalasela ngokubanzi. Ukuba kuyimfuneko, iimvavanyo zentsebenzo ye-welding ziya kwenziwa ukugqiba i-electrode kunye nemilinganiselo yenkqubo efunekayo iya kuthathwa.

Iimbonakalo

1. I-sodium ephantsi ye-hydrogen electrode, yongeza i-0.5% Mo ukuphucula amandla e-weld kunye nokumelana nokubola;

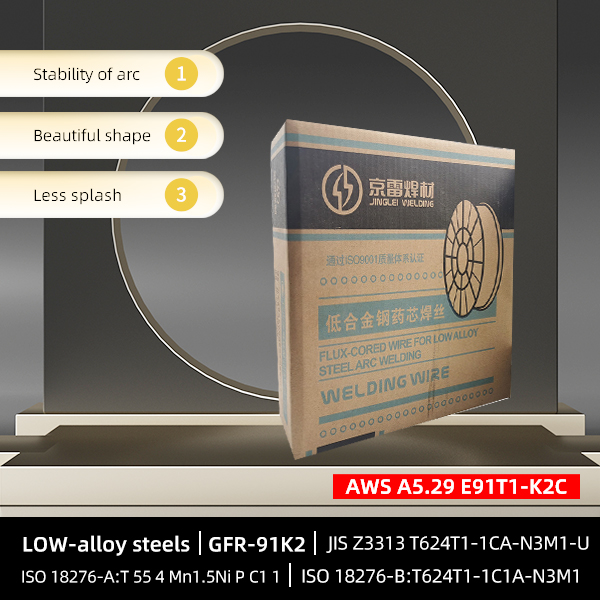

2. I-arc ezinzileyo, i-splash encinci, ukubunjwa kakuhle, kulula ukuyisusa, ukusebenza kwe-X-Ray kugqwesileyo.

Ngokuqhelekileyo khetha i-electrode ehambelanayo ngokwamandla ebakala lentsimbi, kwangaxeshanye kufuneka intsimbi yentsimbi, ukutshintshela amacandelo esinyithi umzali, ubuganga bokuphendula ubungakanani besakhiwo, imilo, igroove kunye noxinzelelo lwezinto zoxinaniso, ezinje ngokubanzi. Ukuqwalasela, isantya sokupholisa se-welding sikhulu kakhulu, sinamandla aphezulu, iimveliso zesitalato ze-weld ziqhekeka ngokulula kwiimeko ezimbi, zihlala zinokukhetha ngaphantsi kwamandla e-electrode yentsimbi yomzali.

Inkampani kunye neFactory

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T IMIGAQO | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| I-AWS IMIGAQO | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| UMZEKELO IXABISO | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | |||||||||

| GB/T IMIGAQO | 390 | 490 | 620*1 | - | 22 | |||||||||

| I-AWS IMIGAQO | 390 | 490 | 620*1 | - | 22 | |||||||||

| UMZEKELO IXABISO | 477 | 570 | 620*1 | 150 / Ubushushu obuqhelekileyo | 28 | |||||||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| UMBANE (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

IINKCUKACHA ZOKUPAKA:

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

Amatyala aqhelekileyo

Isatifikethi

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T IMIGAQO | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| I-AWS IMIGAQO | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| UMZEKELO IXABISO | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | |||||||||

| GB/T IMIGAQO | 390 | 490 | 620*1 | - | 22 | |||||||||

| I-AWS IMIGAQO | 390 | 490 | 620*1 | - | 22 | |||||||||

| UMZEKELO IXABISO | 477 | 570 | 620*1 | 150 / Ubushushu obuqhelekileyo | 28 | |||||||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| UMBANE (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

IINKCUKACHA ZOKUPAKA:

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||