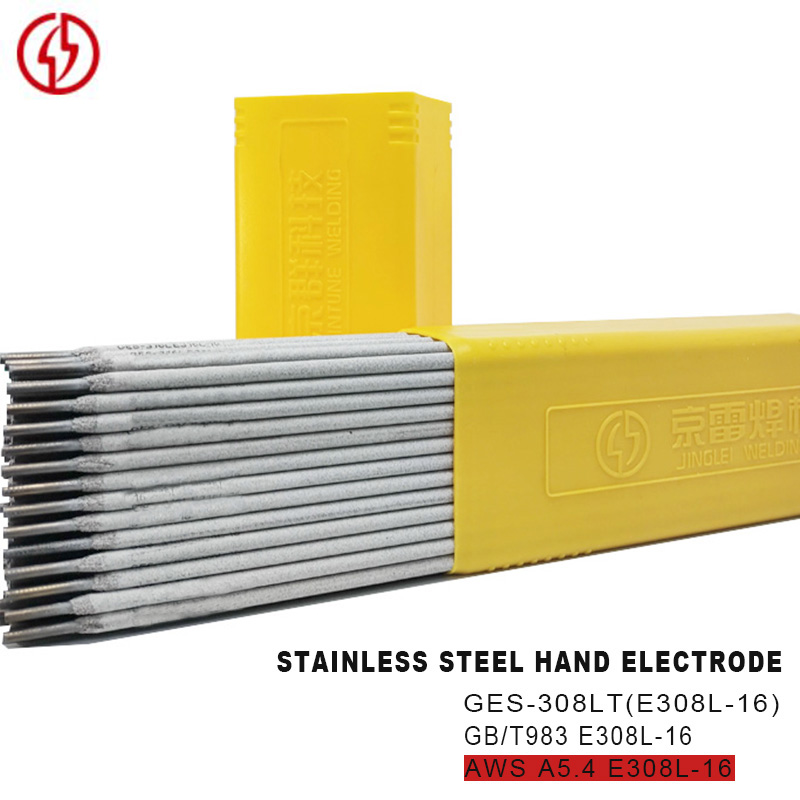

I-AWS E308L-16 Iintsimbi ezingenazintsimbi ezenziwe ngesandla ze-electrode weld fabrication

Isicelo&Mgangatho&Qaphela:

1. Ifanelekile ukuwelda iitanki zokugcina ubushushu obuphantsi, izitya kunye nezinye -196 ℃ izixhobo zokushisa eziphantsi, ezifana ne-SUS304L, njl.

2. Umgangatho esidibene nawo: GB/T983 E308L-16, AWS A5.4 E308L-16 & A5.4M E308L-16, ISO3581-A:E (19 9 L) R 1 2, ISO3581-B:ES308L-16

Electrodes intonga, AWS Classification E308-16, Material Stainless Steel, Process Stick Welding (SMAW), For Material Type Stainless Steel ukuya Stainless Steel, Welding Current Designation AC, DCEP, For Welding Position Flat, Horizontal, Overhead, Vertical-Up

Iimbonakalo

1. I-Titanium calcium stainless steel electrode, eyona nto iphambili yi-18% Cr-9%Ni

2. I-arc ezinzileyo, ukubunjwa okuhle, ama-ripples amahle, i-splashes embalwa, i-de-slagging elula, ukumelana nomlilo okulungileyo kwesikhumba samachiza, ukuxhathisa okulungileyo kwesisu.

3. Ukuqina okugqwesileyo kobushushu obuphantsi kwi -196℃.

Xa iinxalenye kunye neemveliso ezigqityiweyo zilungiswa, ubushushu akufanele bube ngaphantsi koku kulandelayo:

Izinto eziphantsi kwekhabhoni yentsimbi: -20 ℃;

Izinto eziphantsi zentsimbi yolwakhiwo: -15℃.

Ngokuqhelekileyo, ukushisa okuvumelekileyo kwe-welding yeengxenye ze-welding kufuneka kuhlangabezane neemfuno zeThebhile.

Inkampani kunye neFactory

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T IMIGAQO | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-12.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| I-AWS IMIGAQO | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| UMZEKELO IXABISO | 0.037 | 0.85 | 0.5 | 18.2 | 10.7 | 0.15 | 0.027 | 0.005 | 0.05 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | |||||||||

| GB/T IMIGAQO | - | 510 | - | - | 30 | |||||||||

| I-AWS IMIGAQO | - | 520 | - | - | 30 | |||||||||

| UMZEKELO IXABISO | - | 560 | - | 38/-196 | 42 | |||||||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| UMBANE (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

IINKCUKACHA ZOKUPAKA:

| UKWAHLUKANA | UBUDE | PCS/1KG | Ubunzima/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

PHAWULA:

H / W: ukuwelda indawo ethe tye

O / W: phezu-intloko isikhundla welding

Amatyala aqhelekileyo

Isatifikethi

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T IMIGAQO | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-12.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| I-AWS IMIGAQO | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| UMZEKELO IXABISO | 0.037 | 0.85 | 0.5 | 18.2 | 10.7 | 0.15 | 0.027 | 0.005 | 0.05 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | IXABISO LE-IMAPACT J/℃ | UBUDE(%) | |||||||||

| GB/T IMIGAQO | - | 510 | - | - | 30 | |||||||||

| I-AWS IMIGAQO | - | 520 | - | - | 30 | |||||||||

| UMZEKELO IXABISO | - | 560 | - | 38/-196 | 42 | |||||||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| UMBANE (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

IINKCUKACHA ZOKUPAKA:

| UKWAHLUKANA | UBUDE | PCS/1KG | Ubunzima/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

PHAWULA:

H / W: ukuwelda indawo ethe tye

O / W: phezu-intloko isikhundla welding