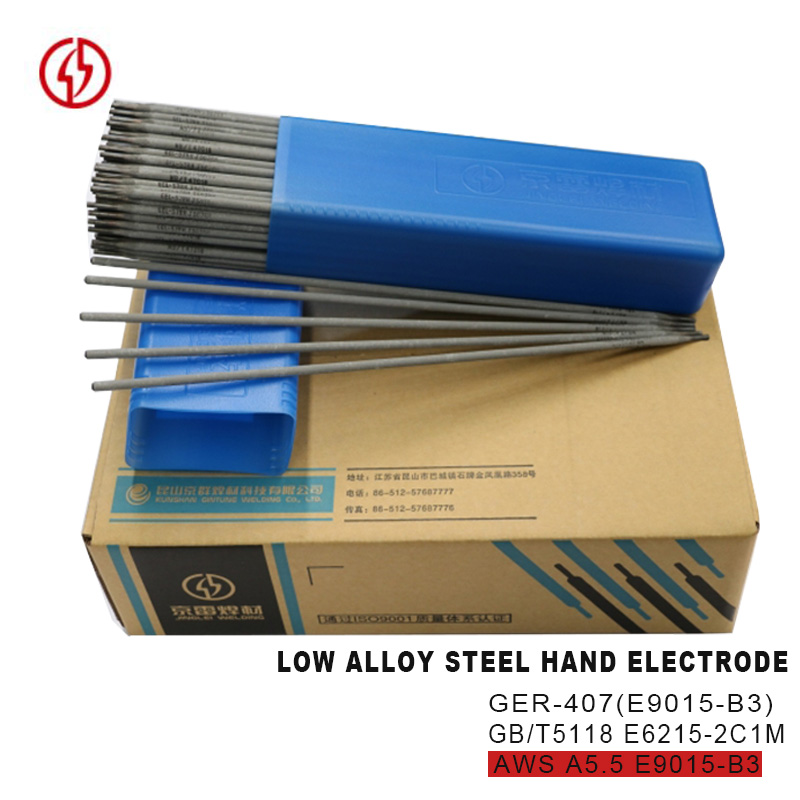

I-AWS A5.13 ENiCrFe-1 ialloyi zenikelo ezisetyenziswa ngesandla kwi-electrode yeWelding

Usetyenziso & noMgangatho

Le Electrode ESEKWE-COBALT INGASETYENZISWA KWISIVIVA SOKUPHAKATHI SESIKHONO SE-SHAFT, UKUSIKA UMDLA WE-CHEMICAL FIBER EQUIPMENT, SAWTOOTH, SCREW PUSH ROD, ubushushu obuphezulu kunye ne-valve yoxinzelelo oluphezulu kunye nempompo yoxinzelelo oluphezulu njl. Ubunzima bomphezulu we-workpiece kufuneka bube ngaphantsi kwe-Ra12.5μm, kunye ne-rust surface, ioli kunye nolunye ukungcola kufuneka lususwe ngokungqongqo. I-matrix ayifanele ibe nokuqhekeka, iipores, isanti kunye nezinye iziphene, kwaye imida kunye neekona kufuneka zijikelezwe. Ngaphambi kokubeka phezulu, amaqondo okushisa ahlukeneyo kufuneka akhethwe ngokwe-substrate material for preheating. Xa imathiriyeli yematrix iyintsimbi ekwaziyo ukumelana nobushushu okanye intsimbi ye-martensitic engasebenzi kakuhle kunye nezinye izinto ezingasebenzi kakuhle, umaleko we-austenitic wentsimbi egqwesileyo kufuneka udityaniswe kumphezulu we-matrix, kwaye emva koko ialloyi esekwe kwi-cobalt kufuneka ibe ngaphezulu emva kokusetyenzwa kakuhle ukuya. phucula ukuxhathisa kokuqhekeka kwaye uphephe iintanda. Nokuba i-AC okanye i-DC arc welding power supply ingasetyenziselwa i-D802 kunye ne-D812 electrode. Dc arc welding power supply iyacetyiswa.

Iimbonakalo

I-GEH-SL12 titanium calcium coated cobalt-base surfacing electrode. Ingxubevange yeCobalt-cr-tungsten isetyenziswa njengengcingo engundoqo. Dc uqhagamshelo reverse kuyacetyiswa. Intsimbi ephezu komhlaba inokugcina ukunganyangeki kakuhle kunye nokumelana nomhlwa kwi-650 ℃. Ngaphambi kwe-welding, kufuneka ibhakwe kwi-300-350 ℃ ngeyure enye; Uluhlu olunzima kwisiseko sesinyithi kufuneka lususwe ukuze lugweme ukuqhekeka kunye nokuphazamiseka. Ngokobungakanani besiseko sentsimbi kunye nohlobo lwesiseko sesinyithi, kufuneka sifudunyezwe kwi-300-600 ℃, kwaye i-welding encinci ye-arc yangoku ifanelekile.

Inkampani kunye neFactory

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T IMIGAQO | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| I-AWS IMIGAQO | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| UMZEKELO IXABISO | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||

| UMBANE (Amp) | Ukuwelda okucaba/okuthe tye | 69-95 | 70-115 | 95-145 | ||||

| Ukuwelda ngokuthe nkqo/ngaphezulu | 55-80 | 65-110 | 80-130 | |||||

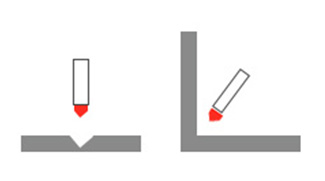

IMIXEKO EQHELEKILEYO

Izatifikethi

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T IMIGAQO | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| I-AWS IMIGAQO | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| UMZEKELO IXABISO | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||

| UMBANE (Amp) | Ukuwelda okucaba/okuthe tye | 69-95 | 70-115 | 95-145 | ||||

| Ukuwelda ngokuthe nkqo/ngaphezulu | 55-80 | 65-110 | 80-130 | |||||