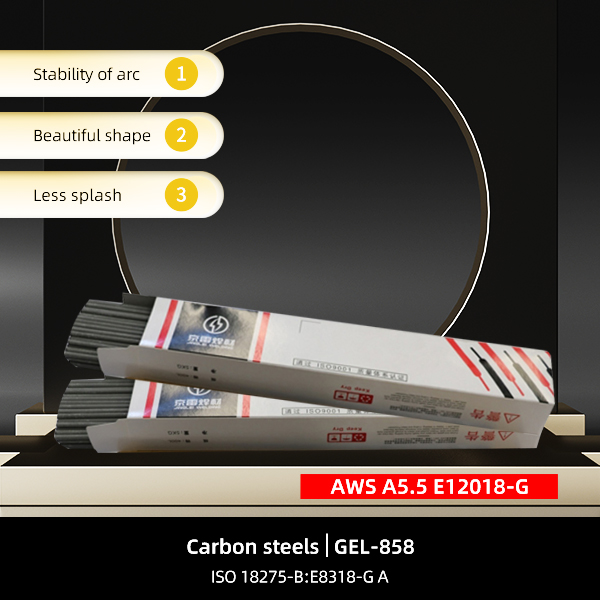

620Mpa Hand Electrode For High Amandla Steel

Isicelo&Standard

1. Ilungele intsimbi ephantsi yealloy yegolide, i-medium carbon steel welding, njengoomatshini bokwakha, oomatshini bezibuko kunye nezinye izihlandlo.

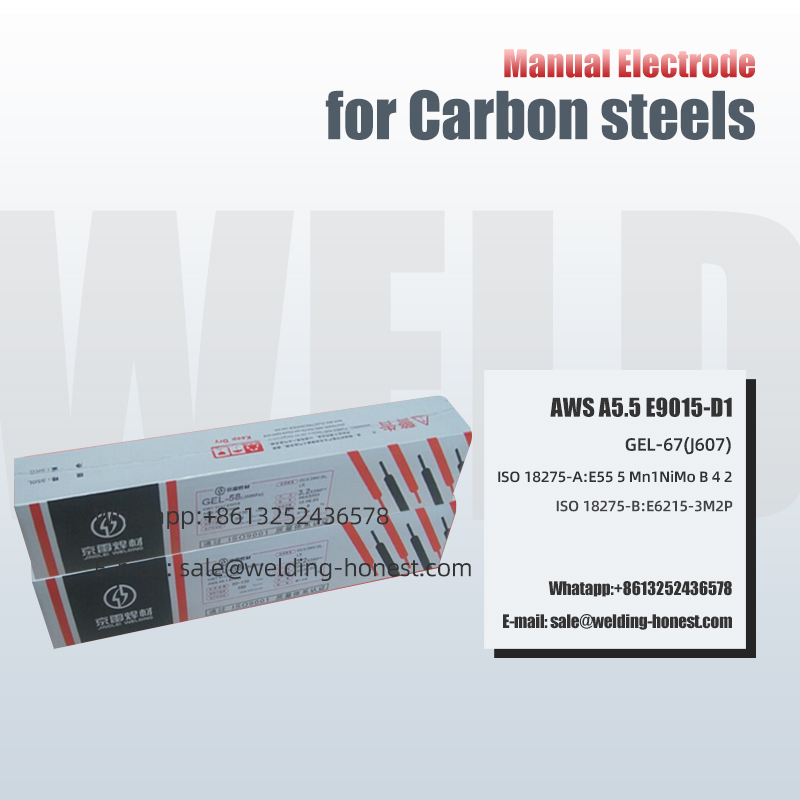

2. Umgangatho esidibene nawo: GB/T32533 E5918-G P, AWS A5.5 E9018-G & A5.5M E6218-G, ISO18275-A: E 55 5 1.5NiMo B 3 2, ISO18275-B: E6218-G P

Preheating kunye nobushushu inter-channel: 150±15℃, unyango ubushushu ngokweemfuno umgangatho welding impahla, 620±15℃*1 iyure post-welding ubushushu unyango.

I-E9016 lulusu oluphantsi lwe-hydrogen potassium ye-alloy yentsimbi ephantsi, i-AC kunye ne-DC yokusetyenziswa kabini, i-AC welding, ekusebenzeni kozinzo, ingaphantsi kancinane kune-DC welding, esetyenziselwa ukuwelda intsimbi ye-carbon medium kunye namandla ahambelanayo. i-alloy high-force structure steel, njengentsimbi ye-15MnVN. Ngaphambi kwe-welding, i-electrode kufuneka ibhakwe kwi-350 ℃ nge-1h, kwaye isetyenziswe ngokubhaka. Xa i-weldment ingqindilili, kufuneka ifudunyezwe ngaphezulu kwe-150℃ kwaye ipholiswe kancinane emva kwe-welding.

Iimbonakalo

1. I-Iron powder low hydrogen hand electrode, ukusebenza kakuhle okuphezulu, i-arc ezinzileyo, i-splash encinci, ukubunjwa okulungileyo, ukuchithwa okulula, ukusebenza kwe-X-ray kuhle kakhulu.

2. Inokumelana nokuqhekeka okulungileyo kunye neempawu ezizinzileyo zoomatshini.

Imodeli ye-electrode yentsimbi ye-J606 yamandla aphezulu: I-E9016-G iimpawu zentsimbi ye-electrode yamandla aphezulu: uhlobo oluphantsi lwe-hydrogen potassium uhlobo olusezantsi lwe-alloy yentsimbi, i-AC kunye ne-DC yokusetyenziswa kabini, inokuthi ibe nokuwelda kwindawo epheleleyo, ukuwelda kwe-AC, ukuzinza kwenkqubo kungaphantsi kancinci DC welding. Injongo: Intsimbi yekhabhoni ephakathi kunye nenqanaba lamandla elihambelanayo eliphantsi kwentsimbi, njengentsimbi ye-15MnVN.

Inkampani kunye neFactory

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T IMIGAQO | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| I-AWS IMIGAQO | - | ≥1.01 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.03 | 0.03 | ≥0.11 |

| UMZEKELO IXABISO | 0.068 | 1.258 | 0.28 | 0.03 | 1.65 | 0.42 | 0.011 | 0.007 | 0.01 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | ||||||

| GB/T IMIGAQO | 490 | 590 | 620*1 | ||||||

| I-AWS IMIGAQO | 530 | 620 | 620*1 | ||||||

| UMZEKELO IXABISO | 600 | 685 | 620*1 | ||||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| UMBANE | H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

PHAWULA:

H / W: ukuwelda indawo ethe tye

O / W: phezu-intloko isikhundla welding

Amatyala aqhelekileyo

Isatifikethi

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T IMIGAQO | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| I-AWS IMIGAQO | - | ≥1.01 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.03 | 0.03 | ≥0.11 |

| UMZEKELO IXABISO | 0.068 | 1.258 | 0.28 | 0.03 | 1.65 | 0.42 | 0.011 | 0.007 | 0.01 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | ||||||

| GB/T IMIGAQO | 490 | 590 | 620*1 | ||||||

| I-AWS IMIGAQO | 530 | 620 | 620*1 | ||||||

| UMZEKELO IXABISO | 600 | 685 | 620*1 | ||||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| UMBANE | H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

PHAWULA:

H / W: ukuwelda indawo ethe tye

O / W: phezu-intloko isikhundla welding