490Mpa Hand Electrode For High Amandla Steel

Isicelo&Mgangatho&Qaphela

1. Ifanele UKUSHIYWA KWESITIMI ESIKABHABHONI KUNYE NENTENYE YE-ALLOY EPHANTSI, KWAKUNYE NAMANDLA OKUFANELEKILEYO WEBOILER, umbhobho, isithuthi, i-BUILDING, BRIDGE KUNYE NEZINYE IZIQULATHO, ezifana ne-Q345.

2. Umgangatho esidibene nawo: GB/T5117 E5018, AWS A5.1 E7018 & A5.1M E4918, ISO2560-A:E 42 3 B 3 2, ISO 2560-B: E4918 A

Ekubeni i-electrode ye-E7018 ithatha kalula umswakama, igcinwe kwi-oven yokumisa i-electrode. I-electrode egcinwe emoyeni inokuphinda ifakwe kwi-350 ~ 400℃ nge-1h ~ 2h. Ukuze ubuyisele iimpawu zesikhumba. Intsimbi ethambileyo inokudityaniswa ngee-electrode ze-E7018 ezingabhakwanga, kodwa amandla okugqibela asenokungabi phezulu ngokwaneleyo.

Iimbonakalo

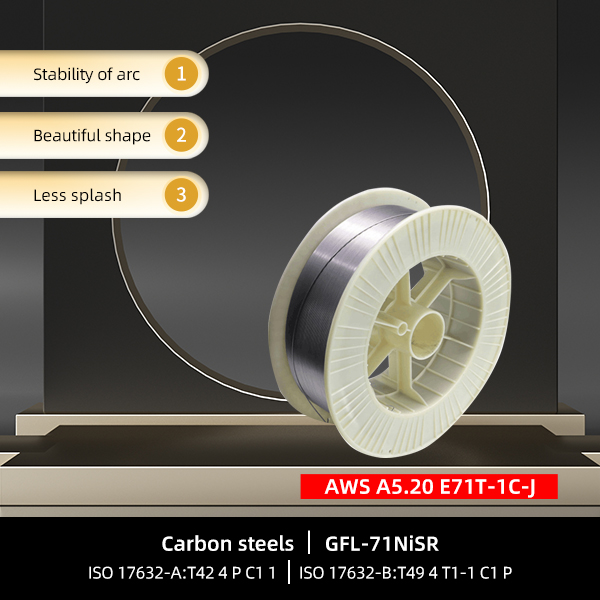

I-Iron powder ephantsi ye-hydrogen yohlobo lwe-electrode yesandla, ukusebenza kakuhle kwe-welding, i-arc ezinzileyo, ukubunjwa okuhle, ukonakala, ukuchaphaza okuncinci, ukutyibilika ngokulula, ukumelana nomlilo kweziyobisi, ukuxhathisa kakuhle kwesisu. Iipropati ezizinzileyo zoomatshini, iplastiki elungileyo kunye nefuthe eliphantsi lobushushu obuphantsi.

I-E7018 ngumgangatho ophezulu we-carbon steel electrode kunye nomgubo wesinyithi ophantsi we-hydrogen potassium yokwaleka. I-electrode inentsebenzo yenkqubo ye-welding egqwesileyo, ukuqina kwe-arc kulungile, akulula ukuvelisa i-bias magnetic evuthelayo, i-welding seam yenza i-clean ecocekileyo kwaye intle, i-splash encinci, i-slag ilula; Intsimbi ye-weld inokuqina kwaye izinzile kwiqondo lokushisa eliphantsi kunye nokumelana nokuqhekeka. Ukusetyenziswa kabini kwe-Ac kunye ne-DC, inokuqhubeka nayo yonke indawo yokuwelda. Uphawu lwayo kukuba ulusu lweziyobisi luqulethe i-iron powder, enokunciphisa inani le-welding layers. Bhaka i-electrode kwi-350 ~ 400 degrees Celsius kwi-1 ~ 2 iiyure, kwaye usebenzise ngokubhaka. Ngokuqhelekileyo le electrode esemgangathweni isetyenziselwa ukuwelda intsimbi yenqanawa (A, B, D okanye E, A36, E36) kunye nezakhiwo ezibalulekileyo zentsimbi ephantsi kwe-alloy yomgangatho ofanayo wamandla, njengamabhoyila, iinqanawa zoxinzelelo kunye namaqonga okuqhuba unxweme, njl.

Inkampani kunye neFactory

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T IMIGAQO | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| I-AWS IMIGAQO | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| UMZEKELO IXABISO | 0.075 | 1.17 | 0.5 | 0.04 | 0.02 | 0.007 | 0.017 | 0.009 | 0.01 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | UBUDE(%) | ||||||

| GB/T IMIGAQO | 400 | 490 | AW | 20 | ||||||

| I-AWS IMIGAQO | 400 | 490 | AW | 22 | ||||||

| UMZEKELO IXABISO | 460 | 555 | AW | 30 | ||||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| UMBANE | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

PHAWULA:

H / W: ukuwelda indawo ethe tye

O / W: phezu-intloko isikhundla welding

Amatyala aqhelekileyo

Isatifikethi

Ukubunjwa kwemveliso kunye neempawu zemishini isingeniso

INXENYE YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T IMIGAQO | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| I-AWS IMIGAQO | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| UMZEKELO IXABISO | 0.075 | 1.17 | 0.5 | 0.04 | 0.02 | 0.007 | 0.017 | 0.009 | 0.01 |

IPROPATI YOOMATSHINI:

| IPROPATI | IZIVUNO ZAMANDLA (MPa) | UKWANDISA AMANDLA (MPa) | UBUSHUSHU℃xh | UBUDE(%) | ||||||

| GB/T IMIGAQO | 400 | 490 | AW | 20 | ||||||

| I-AWS IMIGAQO | 400 | 490 | AW | 22 | ||||||

| UMZEKELO IXABISO | 460 | 555 | AW | 30 | ||||||

IZIQINISEKISO ZOKUSHISA IZIQULATHO:

| INGCACISO YEDIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| UMBANE | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

PHAWULA:

H / W: ukuwelda indawo ethe tye

O / W: phezu-intloko isikhundla welding